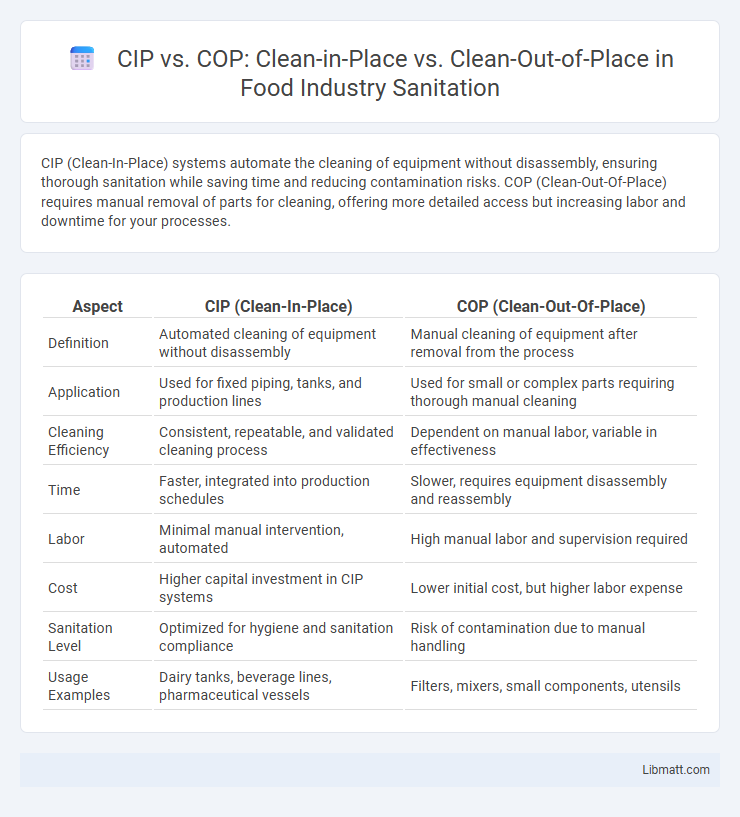

CIP (Clean-In-Place) systems automate the cleaning of equipment without disassembly, ensuring thorough sanitation while saving time and reducing contamination risks. COP (Clean-Out-Of-Place) requires manual removal of parts for cleaning, offering more detailed access but increasing labor and downtime for your processes.

Table of Comparison

| Aspect | CIP (Clean-In-Place) | COP (Clean-Out-Of-Place) |

|---|---|---|

| Definition | Automated cleaning of equipment without disassembly | Manual cleaning of equipment after removal from the process |

| Application | Used for fixed piping, tanks, and production lines | Used for small or complex parts requiring thorough manual cleaning |

| Cleaning Efficiency | Consistent, repeatable, and validated cleaning process | Dependent on manual labor, variable in effectiveness |

| Time | Faster, integrated into production schedules | Slower, requires equipment disassembly and reassembly |

| Labor | Minimal manual intervention, automated | High manual labor and supervision required |

| Cost | Higher capital investment in CIP systems | Lower initial cost, but higher labor expense |

| Sanitation Level | Optimized for hygiene and sanitation compliance | Risk of contamination due to manual handling |

| Usage Examples | Dairy tanks, beverage lines, pharmaceutical vessels | Filters, mixers, small components, utensils |

Introduction to CIP and COP

Clean-in-Place (CIP) is an automated cleaning process designed to clean interior surfaces of equipment without disassembly, commonly used in food, beverage, and pharmaceutical industries to maintain hygiene standards. Clean-out-of-Place (COP) involves manual removal of equipment components for thorough cleaning externally, often utilized when CIP cannot effectively reach all areas or for heavy soil. Understanding the differences between CIP and COP helps you optimize cleaning protocols for efficiency, safety, and regulatory compliance.

What Is Clean-In-Place (CIP)?

Clean-In-Place (CIP) is an automated cleaning method used for internal surfaces of pipes, vessels, and equipment without disassembly. It utilizes a series of chemical solutions, water, and sanitation phases to remove soil, biofilm, and contaminants efficiently. CIP systems are essential in industries such as food processing and pharmaceuticals for maintaining hygiene while reducing downtime.

What Is Clean-Out-Of-Place (COP)?

Clean-Out-Of-Place (COP) refers to the process of manually removing equipment or components from their installed locations for thorough cleaning, often used when intricate parts cannot be effectively cleaned in situ. COP allows for meticulous inspection and sanitization of equipment surfaces, reducing the risk of contamination in food and pharmaceutical manufacturing environments. By understanding your cleaning needs, choosing COP ensures comprehensive hygiene control where Clean-In-Place (CIP) systems are impractical.

Key Differences Between CIP and COP

CIP (Clean-In-Place) and COP (Clean-Out-Of-Place) differ primarily in where and how equipment is cleaned; CIP involves automated cleaning of equipment without disassembly, typically used for fixed process systems, while COP requires manual disassembly and cleaning of parts externally. CIP systems use controlled chemical, temperature, and flow parameters to ensure thorough cleaning and sanitization, optimizing hygiene and minimizing downtime in industries like food and beverage. COP offers flexibility for complex or delicate components that cannot be cleaned effectively in place but involves higher labor and operational costs compared to CIP.

Advantages of CIP Systems

Clean-in-place (CIP) systems offer significant advantages by enabling automated cleaning of complex equipment without disassembly, reducing downtime and labor costs. CIP ensures consistent hygiene through controlled chemical concentrations, temperature, and flow rates, minimizing human error and contamination risks. Your production efficiency improves as CIP systems facilitate faster turnaround times and comply with stringent sanitation standards in industries like food and pharmaceuticals.

Benefits of COP Methods

Clean-out-of-place (COP) methods offer superior cleaning precision by allowing thorough manual scrubbing and targeted application of cleaning agents, which ensures removal of stubborn residues and contaminants. You gain flexibility in cleaning intricate components that cannot be disassembled or adequately cleaned using clean-in-place (CIP) systems. COP techniques also reduce the risk of cross-contamination between batches by enabling complete disassembly and individual cleaning of parts.

Limitations of CIP and COP

CIP (Clean-In-Place) systems face limitations such as difficulty in thoroughly cleaning complex or heavily soiled equipment with intricate geometries, and potential chemical residue buildup due to insufficient rinsing. COP (Clean-Out-Of-Place) methods require disassembly of equipment, which can be time-consuming, labor-intensive, and may increase the risk of contamination during handling. Both CIP and COP face challenges balancing effective sanitation with operational efficiency and worker safety.

Choosing Between CIP and COP: Key Considerations

Choosing between Clean-in-Place (CIP) and Clean-Out-of-Place (COP) depends on equipment complexity, cleaning frequency, and contamination risks. CIP systems are ideal for automated, consistent cleaning in industries like food and pharmaceuticals, reducing downtime and labor costs. COP is preferred for simple equipment or components that require thorough manual cleaning to ensure complete removal of residues and contaminants.

Industry Applications: Where CIP or COP Excels

CIP (Clean-in-Place) is ideal for industries such as dairy, pharmaceuticals, and breweries where maintaining sterile conditions without disassembling equipment is critical for continuous production and contamination control. COP (Clean-Out-of-Place) is preferred in food processing and manufacturing environments where equipment components require thorough manual cleaning to address complex residue or cross-contamination risks. Both methods are essential in biotech and chemical industries, with CIP optimizing efficiency and COP ensuring deep cleaning of removable parts.

Future Trends in Cleaning Technologies

Future trends in cleaning technologies emphasize automation and sustainability in both Clean-In-Place (CIP) and Clean-Out-of-Place (COP) systems, integrating sensors and IoT for real-time monitoring and optimization. Advances in enzymatic and biodegradable cleaning agents are enhancing environmental safety while maintaining efficacy. The adoption of AI-driven data analytics is improving predictive maintenance, reducing downtime, and ensuring consistent hygiene standards across industries.

CIP vs COP (clean-in-place vs clean-out-of-place) Infographic

libmatt.com

libmatt.com