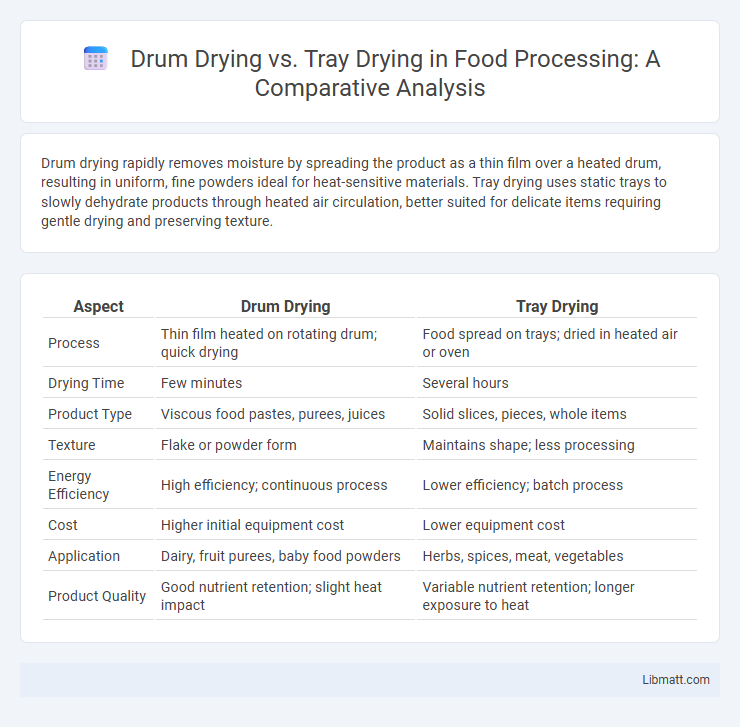

Drum drying rapidly removes moisture by spreading the product as a thin film over a heated drum, resulting in uniform, fine powders ideal for heat-sensitive materials. Tray drying uses static trays to slowly dehydrate products through heated air circulation, better suited for delicate items requiring gentle drying and preserving texture.

Table of Comparison

| Aspect | Drum Drying | Tray Drying |

|---|---|---|

| Process | Thin film heated on rotating drum; quick drying | Food spread on trays; dried in heated air or oven |

| Drying Time | Few minutes | Several hours |

| Product Type | Viscous food pastes, purees, juices | Solid slices, pieces, whole items |

| Texture | Flake or powder form | Maintains shape; less processing |

| Energy Efficiency | High efficiency; continuous process | Lower efficiency; batch process |

| Cost | Higher initial equipment cost | Lower equipment cost |

| Application | Dairy, fruit purees, baby food powders | Herbs, spices, meat, vegetables |

| Product Quality | Good nutrient retention; slight heat impact | Variable nutrient retention; longer exposure to heat |

Introduction to Drum Drying and Tray Drying

Drum drying involves spreading a liquid or slurry onto a heated rotating drum, which rapidly evaporates moisture to create flakes or powders, making it suitable for heat-sensitive materials like fruit purees and dairy products. Tray drying uses stacked trays to hold thin layers of material exposed to warm air circulation, ideal for drying herbs, spices, and small batches of food products with controlled temperature. Your choice between drum drying and tray drying depends on the product's thermal sensitivity, drying time, and production scale.

Principles of Drum Drying

Drum drying involves spreading a liquid or slurry onto the surface of a heated rotating drum, where rapid evaporation of moisture occurs as the material forms a thin film and dries into flakes or powder. This method provides efficient heat transfer and continuous drying, making it suitable for heat-sensitive food products like purees, dairy, and starches. In contrast, tray drying relies on convective hot air circulation for moisture removal, which generally results in longer drying times and lower product uniformity compared to the rapid, conductive heat transfer in drum drying.

Principles of Tray Drying

Tray drying operates by placing materials on perforated trays within a heated chamber where hot air circulates to remove moisture through evaporation. This method ensures uniform drying by controlling temperature, airflow, and humidity, preserving heat-sensitive properties in foods, pharmaceuticals, and chemicals. Your choice of tray drying is ideal for batch processing of delicate products requiring consistent drying conditions and minimal thermal degradation.

Key Equipment and Setup Differences

Drum drying utilizes a heated rotating drum to quickly dry materials by direct contact, making it ideal for viscous or heat-sensitive products, whereas tray drying employs stationary trays with forced hot air circulation for gradual moisture removal suitable for solid and granular items. The drum dryer's continuous operation and compact design contrast with the batch process and larger footprint of tray dryers. Temperature control in drum drying is precise due to direct drum heating, while tray drying relies on ambient air temperature and airflow regulation.

Comparative Energy Efficiency

Drum drying typically offers higher energy efficiency compared to tray drying due to its continuous process and better heat transfer capabilities, resulting in faster drying times and reduced energy consumption. Tray drying involves batch processing with longer exposure times and heat losses from repetitive loading and unloading, leading to increased energy usage. Studies indicate drum drying can consume up to 30-50% less energy per unit of dried product than tray drying, making it more suitable for large-scale industrial applications.

Product Quality and Nutrient Retention

Drum drying offers faster moisture removal, which helps preserve the color and flavor of heat-sensitive products better than tray drying, where longer exposure to heat may degrade nutrients. You can expect higher nutrient retention with drum drying due to its rapid drying process that minimizes thermal damage to vitamins and antioxidants. Tray drying, while more uniform, often results in lower product quality as prolonged drying times can lead to nutrient loss and altered texture.

Throughput and Drying Speed

Drum drying offers higher throughput and faster drying speeds due to continuous contact with heated rotating drums, enabling rapid moisture evaporation ideal for large-scale production. Tray drying involves batch processing with slower moisture removal as material is exposed to hot air in trays, resulting in lower throughput. Industries seeking quick processing and scalability prefer drum drying for its efficiency in handling high-volume, fast-drying applications.

Suitability for Different Food Materials

Drum drying is highly suitable for viscous food materials such as fruit purees, mashed potatoes, and starch pastes, offering rapid drying with minimal nutrient loss. Tray drying better accommodates solid or particulate foods like vegetables, herbs, and meats, ensuring uniform moisture removal without altering texture. Your choice depends on the food's consistency and desired product quality, with drum drying excelling in high-viscosity substances and tray drying fitting for discrete, solid items.

Cost Analysis: Drum Drying vs Tray Drying

Drum drying generally incurs higher initial investment costs due to complex machinery and energy consumption but offers faster drying rates and higher throughput, which can lower operational costs over time. Tray drying involves lower upfront expenses and simpler equipment, but it demands longer drying periods, increasing labor and energy costs per batch. Your choice between drum drying and tray drying should consider production volume, energy efficiency, and long-term maintenance expenses to optimize overall cost-effectiveness.

Conclusion: Choosing the Right Drying Method

Drum drying offers faster processing and better retention of heat-sensitive nutrients, making it ideal for large-scale production of powders and flakes. Tray drying provides more control over drying temperatures and is suitable for delicate products requiring gentle dehydration. Your choice between drum drying and tray drying should balance product quality, processing speed, and equipment availability to optimize efficiency and outcomes.

drum drying vs tray drying Infographic

libmatt.com

libmatt.com