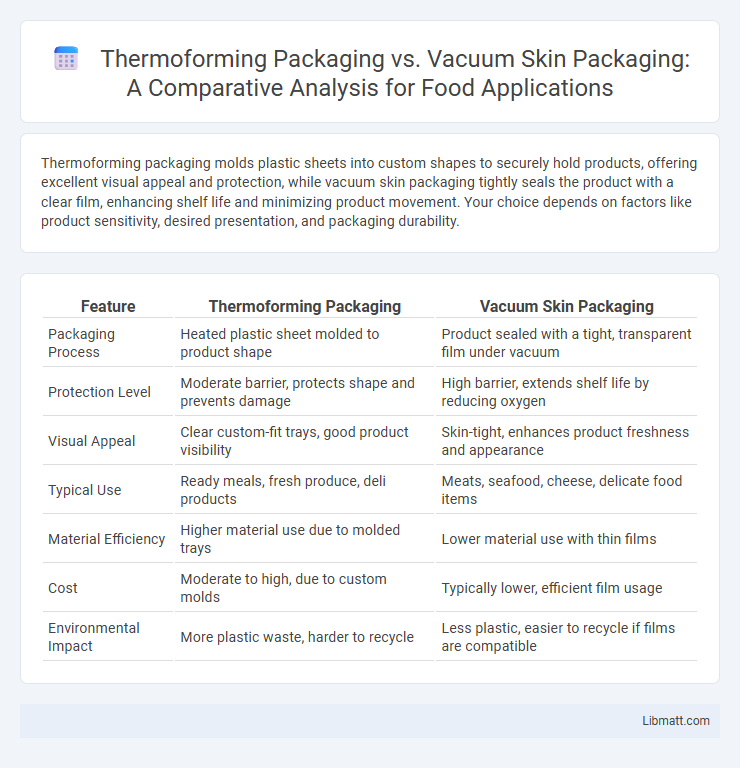

Thermoforming packaging molds plastic sheets into custom shapes to securely hold products, offering excellent visual appeal and protection, while vacuum skin packaging tightly seals the product with a clear film, enhancing shelf life and minimizing product movement. Your choice depends on factors like product sensitivity, desired presentation, and packaging durability.

Table of Comparison

| Feature | Thermoforming Packaging | Vacuum Skin Packaging |

|---|---|---|

| Packaging Process | Heated plastic sheet molded to product shape | Product sealed with a tight, transparent film under vacuum |

| Protection Level | Moderate barrier, protects shape and prevents damage | High barrier, extends shelf life by reducing oxygen |

| Visual Appeal | Clear custom-fit trays, good product visibility | Skin-tight, enhances product freshness and appearance |

| Typical Use | Ready meals, fresh produce, deli products | Meats, seafood, cheese, delicate food items |

| Material Efficiency | Higher material use due to molded trays | Lower material use with thin films |

| Cost | Moderate to high, due to custom molds | Typically lower, efficient film usage |

| Environmental Impact | More plastic waste, harder to recycle | Less plastic, easier to recycle if films are compatible |

Introduction to Thermoforming and Vacuum Skin Packaging

Thermoforming packaging involves heating a plastic sheet until pliable, then molding it into a specific shape to create custom containers and trays ideal for food and industrial products. Vacuum Skin Packaging (VSP) uses a heat-sealed, transparent film that tightly conforms to the contours of the product, offering enhanced protection and extended shelf life by reducing oxygen exposure. Both methods improve product visibility and freshness but differ in application and sealing techniques.

Key Differences Between Thermoforming and Vacuum Skin Packaging

Thermoforming packaging involves heating a plastic sheet until pliable, then molding it into a specific shape to create a rigid container, while vacuum skin packaging (VSP) tightly seals the product with a transparent film under vacuum, conforming to its shape. Thermoforming typically uses thicker plastic for structural support, ideal for rigid trays, whereas VSP excels in extending shelf life by reducing oxygen exposure and preserving freshness. Your choice depends on product protection needs, visual appeal, and cost efficiency in packaging design.

How Thermoforming Packaging Works

Thermoforming packaging works by heating a plastic sheet until it becomes pliable, then shaping it over a mold using vacuum or pressure to create a custom-fitted container. The formed plastic closely contours the product, providing a secure and visually appealing packaging solution that enhances product protection and shelf life. Your choice of thermoforming packaging ensures durability and precision for a wide range of food and consumer goods applications.

How Vacuum Skin Packaging Works

Vacuum Skin Packaging (VSP) works by sealing a product between a pre-formed thermoformed tray and a transparent film, which is vacuum-sealed tightly around the item to eliminate air and extend shelf life. This process creates a secure, tamper-evident package that enhances product visibility and protects against oxidation and contamination. Your products benefit from the firm, skin-tight fit that preserves freshness and reduces the risk of freezer burn compared to traditional thermoforming packaging.

Advantages of Thermoforming Packaging

Thermoforming packaging offers superior design flexibility, allowing for custom shapes and sizes that enhance product presentation and protection. It provides excellent barrier properties against moisture, oxygen, and contaminants, ensuring longer shelf life and freshness. Your products benefit from cost-effective production and faster turnaround times compared to vacuum skin packaging, making it ideal for high-volume manufacturing.

Benefits of Vacuum Skin Packaging

Vacuum Skin Packaging (VSP) extends product shelf life by tightly sealing items in clear, durable film that conforms to their shape, minimizing oxygen and moisture exposure. This method enhances product visibility and appeal, reduces product waste through better preservation, and improves transportation efficiency by minimizing package size and weight. VSP is especially beneficial for fresh meats, cheeses, and delicate food products requiring both protection and attractive presentation.

Packaging Applications: Suitability and Industry Usage

Thermoforming packaging excels in protecting larger, irregularly shaped products such as fresh produce, baked goods, and medical devices, making it widely used in food, pharmaceuticals, and electronics industries. Vacuum skin packaging offers superior sealing for fresh meats, seafood, and cheeses by tightly conforming to the product, enhancing shelf life and presentation, predominantly utilized in meat processing and gourmet food sectors. Your choice depends on product sensitivity, required shelf life, and industry standards, ensuring optimal protection and market appeal.

Sustainability and Environmental Impact

Thermoforming packaging typically uses lightweight plastic films, allowing for material efficiency and recyclability, but its environmental impact varies based on the plastic type and local recycling infrastructure. Vacuum skin packaging (VSP) offers extended shelf life by tightly sealing products, which reduces food waste and thereby indirectly benefits the environment despite often using multilayer films that are less recyclable. Choosing between the two depends on balancing the packaging material's recyclability and its role in minimizing food spoilage to optimize overall sustainability.

Cost Comparison: Thermoforming vs Vacuum Skin Packaging

Thermoforming packaging generally offers lower upfront tooling costs compared to vacuum skin packaging, making it more cost-effective for high-volume production runs. Vacuum skin packaging, however, provides superior product protection and extended shelf life, which can justify higher material and processing expenses in premium or perishable goods markets. Your choice depends on balancing budget constraints with product preservation needs to optimize overall cost efficiency.

Choosing the Right Packaging Solution for Your Product

Thermoforming packaging offers customizable, rigid protection ideal for products requiring secure support and visibility, while vacuum skin packaging excels in extending shelf life by tightly sealing the product with a protective film that enhances freshness and appearance. Your choice depends on product sensitivity, required shelf life, and presentation needs, with thermoforming suited for fragile or multi-compartment items and vacuum skin packaging best for preserving perishable goods. Evaluating factors like cost, durability, and consumer appeal ensures you select the optimal packaging solution for your product's success.

Thermoforming Packaging vs Vacuum Skin Packaging Infographic

libmatt.com

libmatt.com