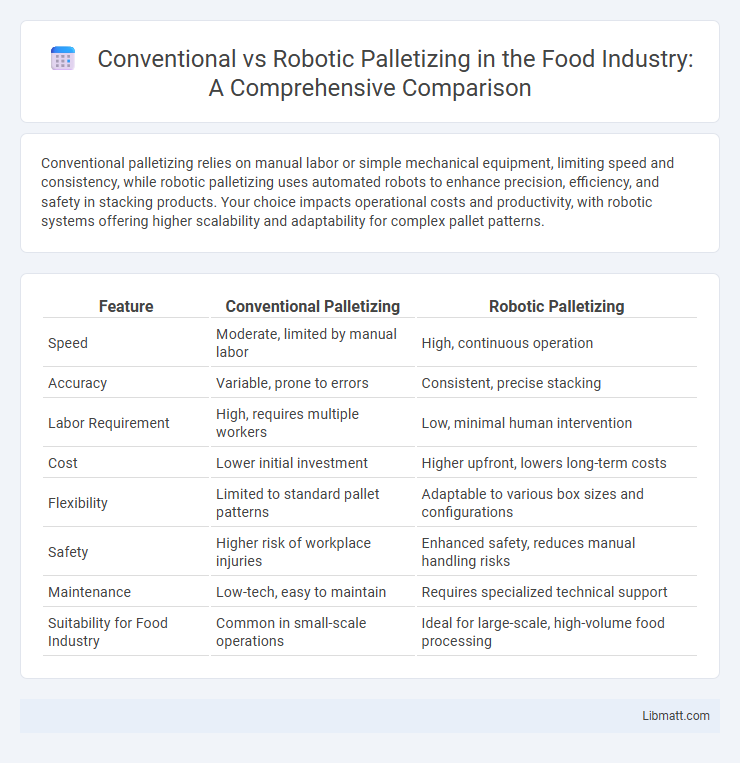

Conventional palletizing relies on manual labor or simple mechanical equipment, limiting speed and consistency, while robotic palletizing uses automated robots to enhance precision, efficiency, and safety in stacking products. Your choice impacts operational costs and productivity, with robotic systems offering higher scalability and adaptability for complex pallet patterns.

Table of Comparison

| Feature | Conventional Palletizing | Robotic Palletizing |

|---|---|---|

| Speed | Moderate, limited by manual labor | High, continuous operation |

| Accuracy | Variable, prone to errors | Consistent, precise stacking |

| Labor Requirement | High, requires multiple workers | Low, minimal human intervention |

| Cost | Lower initial investment | Higher upfront, lowers long-term costs |

| Flexibility | Limited to standard pallet patterns | Adaptable to various box sizes and configurations |

| Safety | Higher risk of workplace injuries | Enhanced safety, reduces manual handling risks |

| Maintenance | Low-tech, easy to maintain | Requires specialized technical support |

| Suitability for Food Industry | Common in small-scale operations | Ideal for large-scale, high-volume food processing |

Introduction to Palletizing Methods

Conventional palletizing relies on manual labor or basic mechanized systems to stack products on pallets, often limiting accuracy and speed. Robotic palletizing uses advanced automation and programmable robots to enhance precision, increase throughput, and handle diverse product types. Industrial sectors integrating robotic palletizers report improved operational efficiency and reduced workplace injuries compared to traditional methods.

Defining Conventional Palletizing

Conventional palletizing involves manual or semi-automated stacking of goods onto pallets, relying heavily on human labor or basic machinery such as conveyors and lifts. This method typically results in lower throughput and higher labor costs compared to advanced solutions. It is commonly used in industries with lower production volumes or where product variation limits automation feasibility.

Overview of Robotic Palletizing

Robotic palletizing uses automated robotic arms to precisely stack products onto pallets, increasing efficiency and reducing labor costs compared to conventional palletizing methods that rely on manual labor or basic machinery. Advanced sensors and AI integration allow robotic systems to handle varied product sizes and weights with high accuracy and speed. Your facility benefits from improved safety, less product damage, and scalable operations through robotic palletizing technology.

Key Components and Technologies Involved

Conventional palletizing relies on manual labor and basic mechanical conveyors, using simple stackers and pallet jacks for arranging goods, which often limits speed and flexibility. Robotic palletizing incorporates advanced technologies such as programmable robotic arms, vision systems, and automated guided vehicles (AGVs) to enhance precision, adaptability, and throughput. Integration of sensors, machine learning algorithms, and IoT connectivity allows robotic systems to handle complex pallet patterns and real-time adjustments, optimizing warehouse efficiency.

Speed and Efficiency Comparison

Conventional palletizing typically relies on manual labor or basic automation, which limits speed and efficiency due to human fatigue and slower cycle times. Robotic palletizing systems significantly enhance throughput by operating continuously with precise, repeatable movements, reducing errors and downtime. Your facility can achieve faster order fulfillment and improved productivity by integrating advanced robotic solutions over conventional methods.

Flexibility and Adaptability in Operations

Conventional palletizing systems rely on fixed mechanical processes, limiting flexibility and requiring manual adjustments to accommodate different product sizes or packaging types. Robotic palletizing offers superior adaptability through programmable arms and advanced sensors, enabling quick transitions between varied product lines and complex stacking patterns. This flexibility significantly enhances operational efficiency and reduces downtime in dynamic production environments.

Labor Requirements and Workforce Impact

Conventional palletizing relies heavily on manual labor, requiring multiple workers to stack and organize products, which increases labor costs and risk of injury. Robotic palletizing automates these tasks, significantly reducing the need for physical labor and improving workplace safety. This transition can lead to workforce shifts, with a greater demand for skilled technicians to oversee robotic systems rather than manual laborers.

Safety Considerations and Workplace Hazards

Conventional palletizing often involves manual labor, increasing risks of musculoskeletal injuries and accidents due to repetitive lifting and handling of heavy loads. Robotic palletizing significantly reduces workplace hazards by automating these tasks, minimizing human exposure to dangerous environments and improving overall safety standards. Your facility can benefit from enhanced safety protocols and lower injury rates by adopting robotic palletizing systems.

Cost Analysis: Initial Investment and ROI

Conventional palletizing typically involves lower initial investment costs but higher ongoing labor expenses, which can reduce long-term ROI. Robotic palletizing requires a significant upfront capital outlay for robots and integration, yet offers faster throughput, reduced labor costs, and improved consistency, resulting in a more favorable ROI over time. Companies analyzing cost should consider scalability, maintenance expenses, and labor market volatility when choosing between conventional and robotic palletizing solutions.

Future Trends in Palletizing Technology

Conventional palletizing relies on manual labor and basic mechanical systems, limiting speed and adaptability in modern logistics environments, whereas robotic palletizing leverages advanced automation, AI, and machine vision to enhance precision and efficiency. Future trends in palletizing technology emphasize increased integration of AI-driven robotics, IoT connectivity for real-time monitoring, and collaborative robots (cobots) designed to work safely alongside human operators. Your operations can benefit from these advancements by adopting scalable, flexible solutions that address growing demands for speed, customization, and reduced labor costs.

Conventional Palletizing vs Robotic Palletizing Infographic

libmatt.com

libmatt.com