Direct injection delivers fuel straight into the combustion chamber, enhancing fuel efficiency and power by allowing precise control over the air-fuel mixture. Indirect heating warms the fuel before combustion, leading to smoother operation but typically lower efficiency compared to direct injection systems.

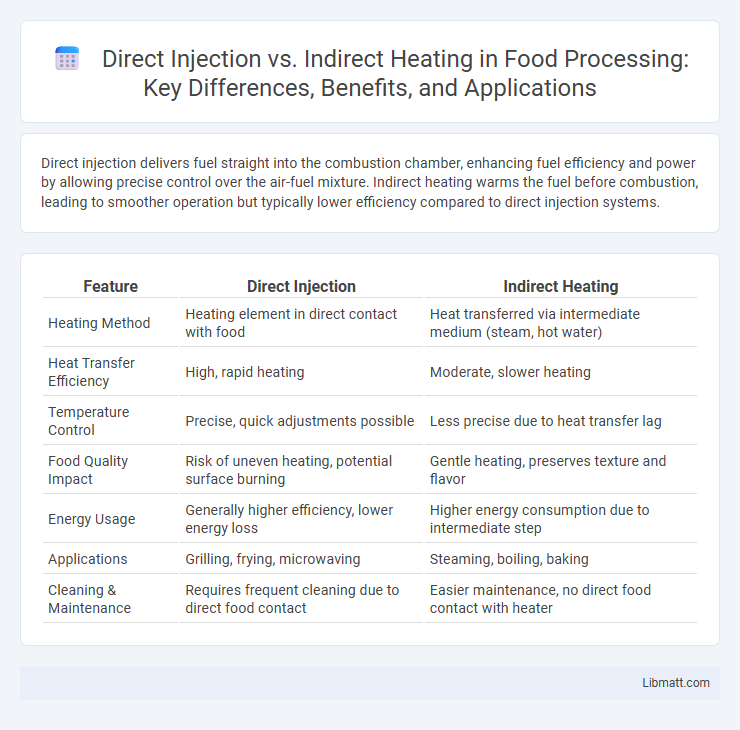

Table of Comparison

| Feature | Direct Injection | Indirect Heating |

|---|---|---|

| Heating Method | Heating element in direct contact with food | Heat transferred via intermediate medium (steam, hot water) |

| Heat Transfer Efficiency | High, rapid heating | Moderate, slower heating |

| Temperature Control | Precise, quick adjustments possible | Less precise due to heat transfer lag |

| Food Quality Impact | Risk of uneven heating, potential surface burning | Gentle heating, preserves texture and flavor |

| Energy Usage | Generally higher efficiency, lower energy loss | Higher energy consumption due to intermediate step |

| Applications | Grilling, frying, microwaving | Steaming, boiling, baking |

| Cleaning & Maintenance | Requires frequent cleaning due to direct food contact | Easier maintenance, no direct food contact with heater |

Introduction to Fuel Heating Technologies

Direct injection systems heat fuel by injecting it straight into the combustion chamber, achieving rapid temperature rise and improved atomization, which enhances engine efficiency. Indirect heating, on the other hand, warms the fuel before injection using external heat exchangers, providing consistent fuel temperature but with slower response times. Your choice between these fuel heating technologies impacts combustion performance, emissions, and overall engine operation.

What is Direct Injection Heating?

Direct injection heating is a process where heat is generated by injecting fuel directly into the combustion chamber, ensuring rapid and efficient energy transfer. This method allows for precise temperature control and reduced energy losses compared to indirect heating techniques. It is commonly used in industrial applications requiring fast heating cycles and high thermal efficiency.

Understanding Indirect Heating Systems

Indirect heating systems utilize a heat exchanger to transfer energy from a combustion chamber or heat source to the target material, preventing direct contact between the flame and your product. This method ensures uniform temperature distribution and reduces contamination risks, making it ideal for processes requiring precise thermal control. Understanding the efficiency and safety advantages of indirect heating can help optimize your industrial heating applications.

Key Differences Between Direct and Indirect Heating

Direct heating transfers heat directly to the material through flames, hot gases, or electric elements, offering rapid temperature increase and energy efficiency. Indirect heating uses a heat transfer medium like steam, water, or thermal oil to transfer heat without direct contact, providing uniform temperature control and preventing contamination. The primary differences lie in heat transfer methods, temperature uniformity, and suitability for sensitive materials or processes requiring strict hygiene standards.

Efficiency Comparison: Direct vs Indirect Methods

Direct injection systems achieve higher thermal efficiency by injecting fuel directly into the combustion chamber, minimizing heat loss and maximizing energy transfer. Indirect heating relies on intermediate heat exchangers or burners, resulting in greater energy dissipation and lower overall efficiency. Studies show direct injection can improve fuel efficiency by up to 15% compared to indirect heating methods in similar applications.

Impact on Fuel Quality and Consistency

Direct injection heating systems offer superior control over fuel delivery, ensuring more consistent combustion and better fuel quality management compared to indirect heating. Indirect heating relies on intermediary fluids or surfaces, which can lead to variations in temperature and fuel degradation, affecting overall efficiency. Your choice between these methods directly influences fuel quality stability and operational consistency, impacting performance and maintenance requirements.

Cost Implications of Each Heating Method

Direct injection systems typically offer lower installation and operational costs because they transfer heat more efficiently by directly heating the target material, reducing energy waste. Indirect heating methods incur higher expenses due to the need for intermediary heat exchangers and extended heat transfer processes, which also increase maintenance requirements. Companies often choose direct injection to minimize long-term energy costs, while indirect heating is preferred in applications requiring precise temperature control despite higher upfront investments.

Maintenance and Operational Considerations

Direct injection heating systems typically require less maintenance as they have fewer components exposed to heat, reducing wear and tear compared to indirect heating systems, which rely on heat exchangers that need regular cleaning to prevent fouling. Indirect heating systems often involve higher operational costs due to energy losses in heat transfer and more frequent inspection requirements to ensure efficient heat exchanger performance. Your choice between the two should consider ease of servicing and the balance between operational efficiency and maintenance demands.

Suitability for Various Industrial Applications

Direct injection heating offers rapid and efficient thermal transfer, making it ideal for industries requiring instant temperature changes, such as chemical processing and food production. Indirect heating provides precise temperature control and uniform heat distribution, better suited for applications like pharmaceuticals and electronics manufacturing where product integrity is crucial. Understanding your specific industrial needs will help determine whether direct injection or indirect heating optimizes performance and energy efficiency.

Choosing the Right Heating System for Your Needs

Direct injection heating delivers rapid, efficient heat by injecting fuel directly into the combustion chamber, making it ideal for applications requiring quick temperature rise and precise control. Indirect heating uses a heat exchanger to transfer warmth, offering cleaner combustion and better suitability for sensitive environments where contamination must be avoided. You should consider factors such as energy efficiency, operational environment, and maintenance requirements to select the heating system best aligned with your specific needs.

Direct Injection vs Indirect Heating Infographic

libmatt.com

libmatt.com