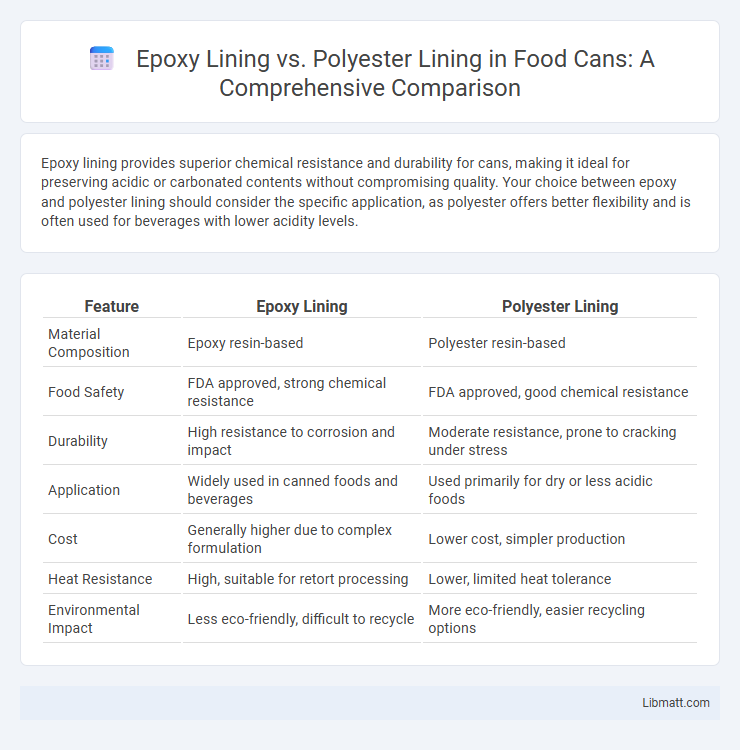

Epoxy lining provides superior chemical resistance and durability for cans, making it ideal for preserving acidic or carbonated contents without compromising quality. Your choice between epoxy and polyester lining should consider the specific application, as polyester offers better flexibility and is often used for beverages with lower acidity levels.

Table of Comparison

| Feature | Epoxy Lining | Polyester Lining |

|---|---|---|

| Material Composition | Epoxy resin-based | Polyester resin-based |

| Food Safety | FDA approved, strong chemical resistance | FDA approved, good chemical resistance |

| Durability | High resistance to corrosion and impact | Moderate resistance, prone to cracking under stress |

| Application | Widely used in canned foods and beverages | Used primarily for dry or less acidic foods |

| Cost | Generally higher due to complex formulation | Lower cost, simpler production |

| Heat Resistance | High, suitable for retort processing | Lower, limited heat tolerance |

| Environmental Impact | Less eco-friendly, difficult to recycle | More eco-friendly, easier recycling options |

Overview of Can Lining Materials

Epoxy lining for cans offers superior corrosion resistance and durability, making it ideal for preserving acidic or carbonated beverages. Polyester lining provides excellent chemical resistance and flexibility but may not perform as well under high-temperature conditions compared to epoxy. Your choice between epoxy and polyester linings depends on the specific beverage properties and storage requirements to ensure optimal product safety and shelf life.

What Is Epoxy Lining?

Epoxy lining is a protective coating applied inside cans to prevent corrosion and contamination, providing a durable and chemical-resistant barrier. It consists of epoxy resins that cure to form a strong, adhesive layer ensuring the safety and longevity of canned products. Your choice of epoxy lining enhances the preservation of food and beverage quality by resisting acidic or moisture-related damage.

What Is Polyester Lining?

Polyester lining is a durable coating applied inside cans to protect the metal from corrosion and prevent contamination of the contents. It provides excellent chemical resistance and is commonly used for packaging food, beverages, and pharmaceuticals due to its inert properties. Polyester linings offer flexibility and adhesion that help maintain the integrity of both the can and its contents during storage and transport.

Chemical Resistance Comparison

Epoxy lining exhibits superior chemical resistance to aggressive substances such as acids, alkalis, and solvents, making it highly effective for preserving cans exposed to harsh chemicals. Polyester lining offers moderate chemical resistance but tends to degrade faster when in contact with strong acids or organic solvents. The durability of epoxy in maintaining can integrity under chemically demanding conditions typically surpasses polyester, ensuring longer service life and reduced contamination risk.

Food and Beverage Safety Considerations

Epoxy lining offers strong chemical resistance and durability, making it suitable for food and beverage cans by preventing contamination and preserving product integrity. Polyester lining provides excellent flexibility and resistance to high temperatures, reducing the risk of flavor alteration and ensuring safety during heat processing. Your choice between epoxy and polyester linings impacts compliance with food safety regulations and the prevention of harmful substance migration into consumables.

Durability and Shelf Life

Epoxy lining offers superior durability compared to polyester lining due to its high resistance to chemicals, corrosion, and abrasion, making it ideal for preserving the integrity of canned products. Polyester lining provides a decent barrier but tends to degrade faster under acidic or high-temperature conditions, which can shorten shelf life. Choosing epoxy lining for your cans ensures extended shelf stability and protection against contamination, preserving product quality for longer periods.

Environmental Impact and Sustainability

Epoxy lining in cans offers strong corrosion resistance but often contains bisphenol A (BPA), raising concerns about environmental toxicity and potential health risks during disposal. Polyester lining, typically BPA-free, provides a more environmentally friendly alternative with better biodegradability and lower chemical leaching, contributing to improved sustainability in packaging. Choosing polyester lining supports reduced ecological footprint and aligns with evolving regulations on safer materials in food and beverage containers.

Regulatory Approvals and Industry Standards

Epoxy lining for cans meets rigorous FDA and EU regulatory approvals, ensuring compliance with food safety standards and resistance to chemical migration. Polyester lining also adheres to global industry standards such as NSF and ISO certifications, offering excellent corrosion resistance and maintaining product integrity. Both materials are frequently evaluated under GMP guidelines, although epoxy linings typically demonstrate superior performance in high-acid and heat applications.

Cost Differences: Epoxy vs Polyester

Epoxy lining typically incurs higher initial costs compared to polyester lining due to more complex application processes and material properties. Polyester lining offers a more cost-effective solution, especially for large-scale can production, while maintaining adequate durability and chemical resistance. Long-term maintenance expenses can be lower for epoxy linings because of their superior adhesion and resistance to corrosion.

Choosing the Right Lining for Your Products

Selecting the appropriate lining for your cans depends on the chemical compatibility and durability requirements of your products. Epoxy lining offers excellent corrosion resistance and strong adhesion, making it ideal for acidic or high-temperature contents, while polyester lining provides superior flexibility and is better suited for products requiring resistance to solvents and alkalis. Your choice should align with the specific formulation and storage conditions to ensure product safety and container integrity.

Epoxy Lining vs Polyester Lining (cans) Infographic

libmatt.com

libmatt.com