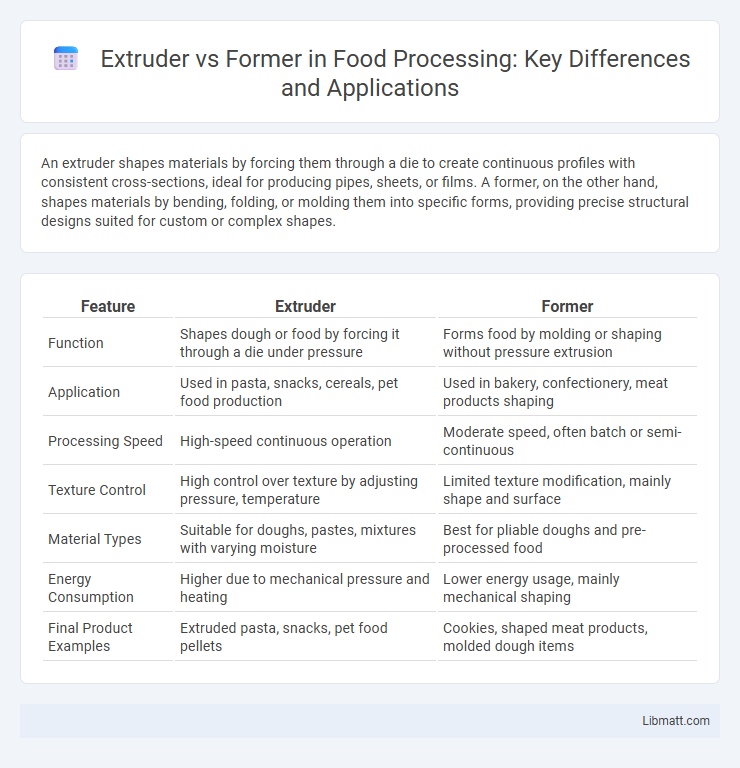

An extruder shapes materials by forcing them through a die to create continuous profiles with consistent cross-sections, ideal for producing pipes, sheets, or films. A former, on the other hand, shapes materials by bending, folding, or molding them into specific forms, providing precise structural designs suited for custom or complex shapes.

Table of Comparison

| Feature | Extruder | Former |

|---|---|---|

| Function | Shapes dough or food by forcing it through a die under pressure | Forms food by molding or shaping without pressure extrusion |

| Application | Used in pasta, snacks, cereals, pet food production | Used in bakery, confectionery, meat products shaping |

| Processing Speed | High-speed continuous operation | Moderate speed, often batch or semi-continuous |

| Texture Control | High control over texture by adjusting pressure, temperature | Limited texture modification, mainly shape and surface |

| Material Types | Suitable for doughs, pastes, mixtures with varying moisture | Best for pliable doughs and pre-processed food |

| Energy Consumption | Higher due to mechanical pressure and heating | Lower energy usage, mainly mechanical shaping |

| Final Product Examples | Extruded pasta, snacks, pet food pellets | Cookies, shaped meat products, molded dough items |

Introduction to Extruders and Formers

Extruders and formers are essential machines in manufacturing, shaping raw materials into continuous profiles or specific shapes. An extruder pushes material through a die to create uniform, elongated products like pipes or sheets, while a former molds materials by bending or pressing them into desired forms. Both devices optimize production efficiency by ensuring consistent dimensions and material properties in various industries such as plastics, food processing, and metal fabrication.

Defining Extruders: Function and Applications

Extruders are industrial machines designed to shape materials by forcing them through a die, commonly used in plastics, food processing, and metal manufacturing. Their function involves melting, mixing, and forming raw materials into continuous profiles or specific shapes, enabling mass production with high precision and uniformity. Applications of extruders range from producing plastic films, pipes, and sheets to creating pasta, pet food, and rubber products.

Understanding Formers: Purpose and Uses

Formers serve the primary purpose of shaping and molding materials into consistent, repeatable forms, essential in industries like manufacturing and construction. Typically used in processes involving materials such as plastics, metals, or composites, formers ensure structural integrity and precise dimensions. Their applications span from producing automotive parts to architectural components where uniformity and durability are critical.

Key Differences Between Extruders and Formers

Extruders shape materials by forcing them through a die to create continuous profiles, commonly used in plastic and metal manufacturing, whereas formers primarily manipulate materials by bending, stamping, or pressing to achieve desired shapes, often seen in sheet metal and glass production. Extrusion allows for consistent cross-sectional geometries and is ideal for producing long, uniform parts, while forming offers greater flexibility in creating complex, three-dimensional shapes. The extrusion process typically involves heating and high pressure, contrasting with forming, which relies more on mechanical deformation at room or elevated temperatures.

Advantages of Using an Extruder

An extruder offers precise control over product shape and consistency, making it ideal for producing uniform materials in industries like food processing and plastics. Its continuous operation enhances production efficiency and reduces labor costs compared to former machines. You benefit from better scalability and customization options, ensuring your products meet specific quality standards.

Benefits of Implementing a Former

Implementing a former offers precise shaping and uniform thickness control, enhancing product consistency and reducing material waste in manufacturing processes. Formers enable faster production speeds by streamlining the shaping phase without compromising the integrity of the material. Your operations benefit from lower energy consumption and reduced maintenance costs compared to extruders, making formers a cost-effective solution for high-volume, quality-focused production.

Common Industries Using Extruders and Formers

Extruders are widely used in industries such as plastics manufacturing, food processing, and pharmaceuticals for shaping materials through continuous profiles, while formers find extensive application in textiles, metalworking, and woodworking for creating specific shapes or patterns. The plastic extrusion industry heavily relies on extruders for producing pipes, sheets, and films, whereas formers are crucial in automotive manufacturing and packaging for bending and molding components. Both machines enhance production efficiency, with extruders excelling in volume output and formers providing precision shaping across diverse industrial applications.

Material Compatibility: Extruder vs Former

Extruders excel in processing a wide range of thermoplastics, including ABS, PLA, and nylon, due to their precise temperature control and consistent melting capabilities. Formers are typically best suited for softer or pre-formed materials that require shaping without melting, such as foam or certain flexible sheets. Understanding your material compatibility ensures you choose the right equipment for optimal manufacturing efficiency and product quality.

Choosing the Right Machine for Your Process

Selecting the right machine between an extruder and former depends on your material type and product specifications. Extruders excel in shaping continuous profiles from plastic, metal, or food materials through a die, ideal for complex cross-sections. Formers suit applications requiring precise shaping and cutting of sheets or films, ensuring your process efficiency and product quality align with operational goals.

Future Trends in Extrusion and Forming Technology

Future trends in extrusion and forming technology emphasize advanced automation, smart sensors, and AI integration to enhance precision and efficiency. Extruders are increasingly adopting sustainable materials and energy-efficient processes, while formers are evolving with adaptive tooling and real-time quality monitoring. Your manufacturing capabilities will benefit from these innovations through improved product consistency and faster production cycles.

Extruder vs Former Infographic

libmatt.com

libmatt.com