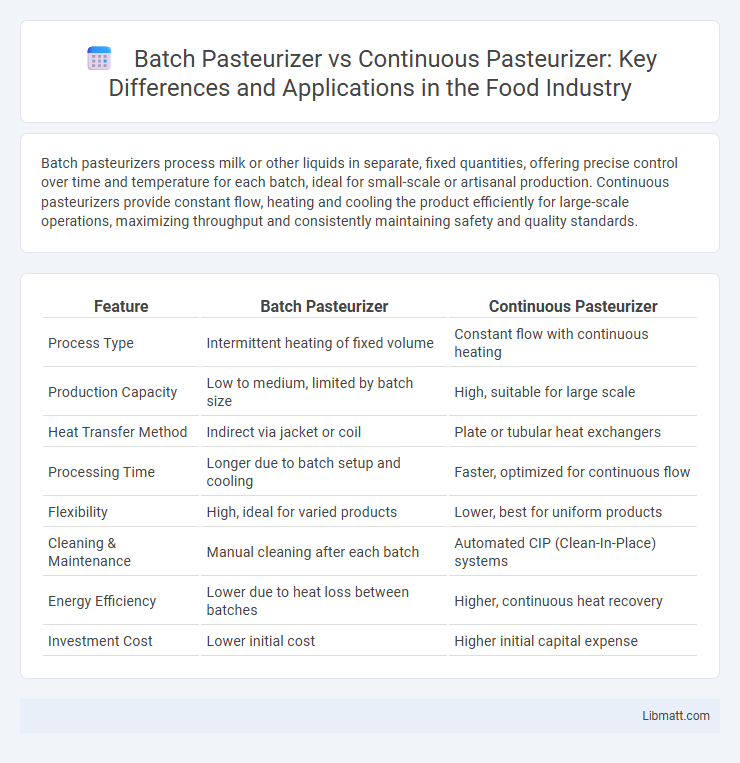

Batch pasteurizers process milk or other liquids in separate, fixed quantities, offering precise control over time and temperature for each batch, ideal for small-scale or artisanal production. Continuous pasteurizers provide constant flow, heating and cooling the product efficiently for large-scale operations, maximizing throughput and consistently maintaining safety and quality standards.

Table of Comparison

| Feature | Batch Pasteurizer | Continuous Pasteurizer |

|---|---|---|

| Process Type | Intermittent heating of fixed volume | Constant flow with continuous heating |

| Production Capacity | Low to medium, limited by batch size | High, suitable for large scale |

| Heat Transfer Method | Indirect via jacket or coil | Plate or tubular heat exchangers |

| Processing Time | Longer due to batch setup and cooling | Faster, optimized for continuous flow |

| Flexibility | High, ideal for varied products | Lower, best for uniform products |

| Cleaning & Maintenance | Manual cleaning after each batch | Automated CIP (Clean-In-Place) systems |

| Energy Efficiency | Lower due to heat loss between batches | Higher, continuous heat recovery |

| Investment Cost | Lower initial cost | Higher initial capital expense |

Introduction to Pasteurization Methods

Batch pasteurizers heat liquids in separate, controlled quantities ensuring precise temperature management for each batch, ideal for artisanal or small-scale production. Continuous pasteurizers use a constant flow system, quickly heating and cooling the product, maximizing efficiency and throughput in large-scale operations. Your choice between these methods depends on production volume, product type, and desired process control.

What Is a Batch Pasteurizer?

A batch pasteurizer heats a specific volume of liquid in a container for a set time to eliminate pathogens, ensuring product safety and quality. This method allows precise control over temperature and time but processes limited quantities per cycle, making it ideal for small-scale or specialty productions. Your choice between batch pasteurizer and continuous pasteurizer depends on production volume and operational efficiency.

What Is a Continuous Pasteurizer?

A continuous pasteurizer is an advanced heat treatment system designed to efficiently pasteurize large volumes of liquids, such as milk or juice, by continuously flowing the product through heated tubes or plates at precise temperatures. Unlike batch pasteurizers, which process fixed volumes in separate containers, continuous pasteurizers maintain consistent temperature control and minimize contamination risks, ensuring higher throughput and uniform product quality. Your production line benefits from improved energy efficiency and reduced processing time with continuous pasteurization technology.

Workflow Differences: Batch vs. Continuous Systems

Batch pasteurizers process milk or liquid products in discrete volumes, heating and cooling each batch separately, which allows for precise control over processing time and temperature. Continuous pasteurizers operate by flowing the product through a heated section without interruption, enabling higher throughput and consistent processing parameters. Your choice depends on production scale and workflow efficiency, with batch systems suited for small or diverse batches and continuous systems ideal for large-scale, uniform production.

Efficiency and Throughput Comparison

Continuous pasteurizers offer higher efficiency and throughput compared to batch pasteurizers due to their ability to process liquids nonstop, reducing downtime between cycles. Batch pasteurizers are better suited for smaller volumes with flexibility in handling different products but have slower processing speeds and lower overall output. Your choice should depend on production scale; continuous systems maximize output for large-scale operations while batch systems provide more control over product variability.

Quality and Consistency of Pasteurized Products

Batch pasteurizers offer precise control over processing time and temperature, resulting in high-quality products with uniform microbial reduction. Continuous pasteurizers provide consistent pasteurization through steady flow and rapid heating, ensuring uniform product quality ideal for large-scale production. Your choice depends on whether batch consistency or continuous throughput best suits your product quality requirements.

Cost Implications and Operational Expenses

Batch pasteurizers generally incur higher labor and maintenance costs due to frequent cleaning and manual monitoring, leading to increased operational expenses. Continuous pasteurizers, though requiring a higher initial investment, offer cost savings over time through automation, energy efficiency, and reduced labor input. The scalability of continuous systems further enhances cost-effectiveness in large-scale production compared to batch processing.

Maintenance and Equipment Requirements

Batch pasteurizers require more frequent maintenance due to their repetitive heating and cooling cycles and typically involve simpler mechanical components, making repairs straightforward but labor-intensive. Continuous pasteurizers incorporate advanced automation and complex heat exchange systems, demanding specialized maintenance personnel and higher equipment investment but offering greater reliability and lower downtime. Equipment requirements for batch systems emphasize flexibility and manual monitoring, whereas continuous systems prioritize integration with automated control systems and consistent throughput efficiency.

Best Use Cases for Batch and Continuous Pasteurizers

Batch pasteurizers are best suited for small-scale production, specialty products, and when precise control over each batch is essential, such as in artisanal dairy or craft beverage manufacturing. Continuous pasteurizers excel in high-volume operations requiring consistent flow and efficiency, making them ideal for large-scale dairy plants or juice processing facilities. Your choice depends on production volume, product type, and quality control needs, with batch systems favoring flexibility and continuous systems prioritizing speed.

Choosing the Right Pasteurizer for Your Business

Choosing the right pasteurizer for your business depends on production volume and product consistency requirements. Batch pasteurizers provide flexibility for small to medium-scale operations with varied products, ensuring precise control over each batch's temperature and timing. Continuous pasteurizers are ideal for high-volume production, offering efficiency and consistent heating for liquid products like milk and juice, minimizing downtime and labor costs.

batch pasteurizer vs continuous pasteurizer Infographic

libmatt.com

libmatt.com