Inversion sugar, created by splitting sucrose into glucose and fructose, offers a natural alternative with a balanced sweetness compared to high-fructose corn syrup (HFCS), which is industrially processed and often contains higher fructose levels. Understanding the differences in their composition and impact on blood sugar can help you make informed choices for healthier recipes or product formulations.

Table of Comparison

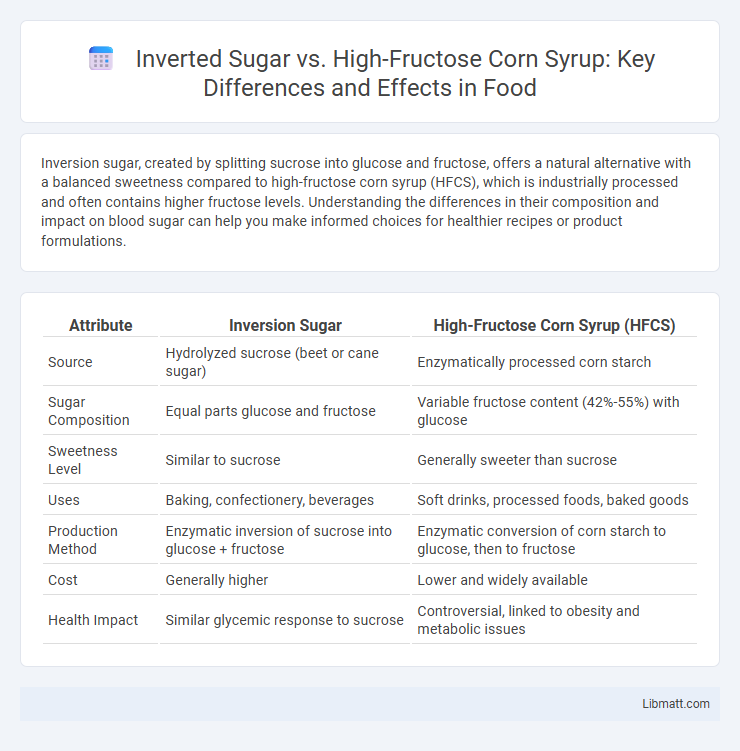

| Attribute | Inversion Sugar | High-Fructose Corn Syrup (HFCS) |

|---|---|---|

| Source | Hydrolyzed sucrose (beet or cane sugar) | Enzymatically processed corn starch |

| Sugar Composition | Equal parts glucose and fructose | Variable fructose content (42%-55%) with glucose |

| Sweetness Level | Similar to sucrose | Generally sweeter than sucrose |

| Uses | Baking, confectionery, beverages | Soft drinks, processed foods, baked goods |

| Production Method | Enzymatic inversion of sucrose into glucose + fructose | Enzymatic conversion of corn starch to glucose, then to fructose |

| Cost | Generally higher | Lower and widely available |

| Health Impact | Similar glycemic response to sucrose | Controversial, linked to obesity and metabolic issues |

Introduction to Inversion Sugar and High-Fructose Corn Syrup

Inversion sugar is a mixture of glucose and fructose created by hydrolyzing sucrose, offering enhanced sweetness and moisture retention in food products. High-fructose corn syrup (HFCS) is a liquid sweetener derived from corn starch, processed to increase fructose content, commonly used in beverages and processed foods for its cost-effectiveness and sweetness profile. Understanding the differences between inversion sugar and HFCS can help you choose the right sweetener for your specific culinary or manufacturing needs.

Chemical Structure and Composition

Inversion sugar is a mixture of glucose and fructose obtained by hydrolyzing sucrose, resulting in a roughly 1:1 ratio of these monosaccharides. High-fructose corn syrup (HFCS) is produced by enzymatically converting glucose from corn starch into fructose, varying in fructose content from 42% to 90%, depending on the type. Chemically, inversion sugar consists of free glucose and fructose molecules, whereas HFCS is a liquid sweetener with specific fructose-to-glucose ratios tailored for industrial applications.

Production Processes Compared

Inversion sugar is produced by hydrolyzing sucrose into glucose and fructose through acid or enzymatic methods, resulting in a sweeter and more soluble syrup ideal for confectionery. High-fructose corn syrup (HFCS) is manufactured by enzymatically converting corn starch into glucose, followed by isomerization to increase fructose content, commonly used in beverages and processed foods for sweetness and shelf life extension. Understanding these distinct production processes helps you choose the appropriate sweetener based on product formulation, sweetness level, and textural requirements.

Sweetness and Taste Profiles

Inversion sugar contains nearly equal parts glucose and fructose, resulting in a sweetness level close to that of sucrose with a clean, mild taste profile ideal for balanced flavor enhancement. High-fructose corn syrup (HFCS), especially HFCS-55, has a higher fructose content, making it significantly sweeter than inversion sugar and lending a more intense, syrupy sweetness with subtle caramel notes. The choice between inversion sugar and HFCS impacts the overall sweetness intensity and flavor characteristics in food and beverage formulations.

Applications in Food and Beverage Industry

Inversion sugar is widely used in bakery products, confectionery, and beverages due to its ability to retain moisture, enhance sweetness, and prevent crystallization, improving texture and shelf life. High-fructose corn syrup (HFCS) dominates in soft drinks, processed foods, and desserts because of its cost-effectiveness and high sweetness level that boosts flavor intensity and product stability. Your choice between inversion sugar and HFCS depends on specific formulation needs, including sweetness profile, texture control, and labeling preferences within the food and beverage industry.

Nutritional Value and Caloric Content

Inversion sugar and high-fructose corn syrup (HFCS) both serve as sweeteners but differ in nutritional value and caloric content. Inversion sugar is a mixture of glucose and fructose created by splitting sucrose, providing approximately 4 calories per gram similar to HFCS, which also contains a blend of these sugars but may vary in fructose concentration from 42% to 55%. Your choice between the two can impact blood sugar levels and metabolism differently due to the distinct ratios of fructose and glucose they contain.

Health Impacts and Controversies

Inversion sugar, a mixture of glucose and fructose, is often lauded for its natural origins and slightly easier digestibility compared to high-fructose corn syrup (HFCS), which undergoes extensive enzymatic processing. HFCS has been linked to increased risks of obesity, insulin resistance, and metabolic disorders due to its high fructose content and widespread use in processed foods. Your health may benefit from choosing inversion sugar over HFCS, but moderation remains key amid ongoing debates about their long-term effects.

Labeling and Regulatory Differences

Inversion sugar is typically labeled as invert sugar or inverted syrup, containing a roughly equal mix of glucose and fructose, while high-fructose corn syrup (HFCS) must be specified by its fructose content, such as HFCS-42 or HFCS-55, under food regulations. Regulatory agencies classify HFCS under corn syrup derivatives, often subjected to stricter scrutiny due to its industrial processing and higher fructose levels, whereas inversion sugar, often considered a natural enzymatic product, faces fewer labeling restrictions. Your choice between these sweeteners impacts compliance with labeling laws and consumer transparency, especially in markets with stringent nutritional disclosure requirements.

Market Trends and Consumer Preferences

Inversion sugar is gaining traction in the market due to its natural production process and perceived health benefits, appealing to consumers seeking clean-label ingredients. High-fructose corn syrup remains dominant because of its cost-effectiveness and widespread availability in processed foods and beverages. Your choice between these sweeteners can influence product positioning, given the growing consumer preference for natural and less processed options.

Sustainability and Environmental Considerations

Inversion sugar is derived from sucrose enzymatic hydrolysis, promoting sustainability by utilizing natural, renewable sugar sources and generating less industrial waste compared to high-fructose corn syrup (HFCS), which is primarily produced from genetically modified corn with significant pesticide and fertilizer inputs. HFCS production demands more energy and water, contributing to higher greenhouse gas emissions and environmental degradation, whereas inversion sugar processing is generally less resource-intensive with a smaller carbon footprint. Sustainable sourcing and reduced chemical usage position inversion sugar as a more environmentally friendly alternative in food manufacturing.

Inversion Sugar vs High-Fructose Corn Syrup Infographic

libmatt.com

libmatt.com