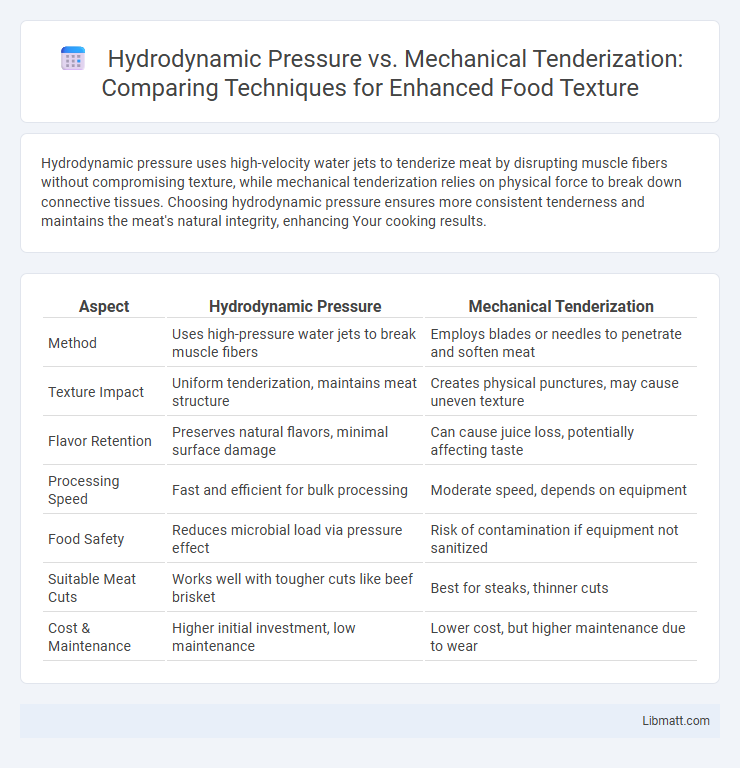

Hydrodynamic pressure uses high-velocity water jets to tenderize meat by disrupting muscle fibers without compromising texture, while mechanical tenderization relies on physical force to break down connective tissues. Choosing hydrodynamic pressure ensures more consistent tenderness and maintains the meat's natural integrity, enhancing Your cooking results.

Table of Comparison

| Aspect | Hydrodynamic Pressure | Mechanical Tenderization |

|---|---|---|

| Method | Uses high-pressure water jets to break muscle fibers | Employs blades or needles to penetrate and soften meat |

| Texture Impact | Uniform tenderization, maintains meat structure | Creates physical punctures, may cause uneven texture |

| Flavor Retention | Preserves natural flavors, minimal surface damage | Can cause juice loss, potentially affecting taste |

| Processing Speed | Fast and efficient for bulk processing | Moderate speed, depends on equipment |

| Food Safety | Reduces microbial load via pressure effect | Risk of contamination if equipment not sanitized |

| Suitable Meat Cuts | Works well with tougher cuts like beef brisket | Best for steaks, thinner cuts |

| Cost & Maintenance | Higher initial investment, low maintenance | Lower cost, but higher maintenance due to wear |

Introduction to Meat Tenderization Techniques

Meat tenderization techniques like hydrodynamic pressure and mechanical tenderization target the breakdown of muscle fibers and connective tissues to enhance texture and flavor. Hydrodynamic pressure uses high-velocity liquid shockwaves that disrupt muscle structures without physical blades, preserving moisture while increasing tenderness. Mechanical tenderization, by contrast, employs blades or needles to physically pierce the meat, improving tenderness and marination absorption but potentially increasing microbial risks if not handled properly.

Understanding Hydrodynamic Pressure in Meat Processing

Hydrodynamic pressure in meat processing uses high-velocity water jets to disrupt muscle fibers, enhancing tenderness without compromising the meat's structural integrity. This method contrasts with mechanical tenderization, which physically punctures or cuts the meat, potentially causing moisture loss and contamination. You benefit from hydrodynamic pressure's ability to improve meat texture while maintaining juiciness and food safety.

What is Mechanical Tenderization?

Mechanical tenderization is a process that uses blades, needles, or blades to physically break down muscle fibers and connective tissues in meat, enhancing its tenderness and improving texture. This technique increases meat's surface area, allowing marinades and seasonings to penetrate more effectively and reducing cooking time. Unlike hydrodynamic pressure, which relies on high-pressure water jets to disrupt muscle structure, mechanical tenderization directly punctures the meat to achieve the desired softness.

Mechanisms: How Hydrodynamic Pressure Works

Hydrodynamic pressure tenderization relies on high-velocity water jets that generate shockwaves, disrupting muscle fibers and connective tissues at a microscopic level. This process enhances meat texture by breaking down structural proteins more uniformly compared to mechanical methods. The rapid application of pressure ensures deeper penetration without compromising the meat's surface integrity, resulting in improved tenderness and flavor retention.

Mechanisms: How Mechanical Tenderization Works

Mechanical tenderization works by physically breaking down muscle fibers and connective tissues through repeated needle or blade punctures, improving meat texture and juiciness. This process increases enzyme access, enhancing protein breakdown for a more tender bite. Your steaks become softer as the mechanical action disrupts the dense structure of the meat.

Effects on Meat Texture and Quality

Hydrodynamic pressure improves meat texture by evenly disrupting muscle fibers without compromising juiciness, resulting in tender, succulent cuts. Mechanical tenderization, involving blades or needles, breaks down connective tissue but can cause uneven texture and potential moisture loss. Your choice between these methods affects overall meat quality, balancing tenderness with preservation of flavor and moisture.

Safety Concerns and Foodborne Pathogens

Hydrodynamic pressure effectively reduces foodborne pathogens by applying intense pressure waves that disrupt microbial cells without the heat damage associated with mechanical tenderization. Mechanical tenderization, involving blade penetration, can introduce pathogens from the surface into the interior of meat, increasing contamination risks. Understanding these safety concerns helps you choose processing methods that minimize pathogen exposure and enhance food safety.

Industrial Applications and Scalability

Hydrodynamic pressure technology offers high scalability for industrial meat processing due to its uniform tenderization and minimal impact on product structure, making it ideal for large-scale operations requiring consistent quality. Mechanical tenderization, while widely used, often presents challenges in scalability as it relies on physical penetration methods that can damage product integrity and vary in effectiveness across batch sizes. Your choice between these methods will depend on your production volume, desired texture, and the importance of maintaining meat quality at scale.

Consumer Perception and Market Trends

Hydrodynamic pressure tenderization gains consumer favor due to its non-invasive, chemical-free process that preserves natural meat texture and flavor. Mechanical tenderization faces scrutiny as consumers associate needle-based techniques with increased risk of contamination and compromised product quality. Market trends indicate a growing demand for clean-label, minimally processed meats, driving innovation toward hydrodynamic pressure technologies in premium and health-conscious segments.

Future Prospects in Meat Tenderization Technology

Hydrodynamic pressure technology offers a scalable, non-thermal method to enhance meat tenderness while preserving nutritional quality and flavor profiles, positioning it as a promising alternative to traditional mechanical tenderization. Advances in high-pressure processing equipment and automation are expected to reduce energy consumption and increase throughput efficiency. Ongoing research into combined treatments with enzymatic or ultrasonic methods could further improve tenderness and texture uniformity, expanding applications across various meat types and cuts.

Hydrodynamic Pressure vs Mechanical Tenderization Infographic

libmatt.com

libmatt.com