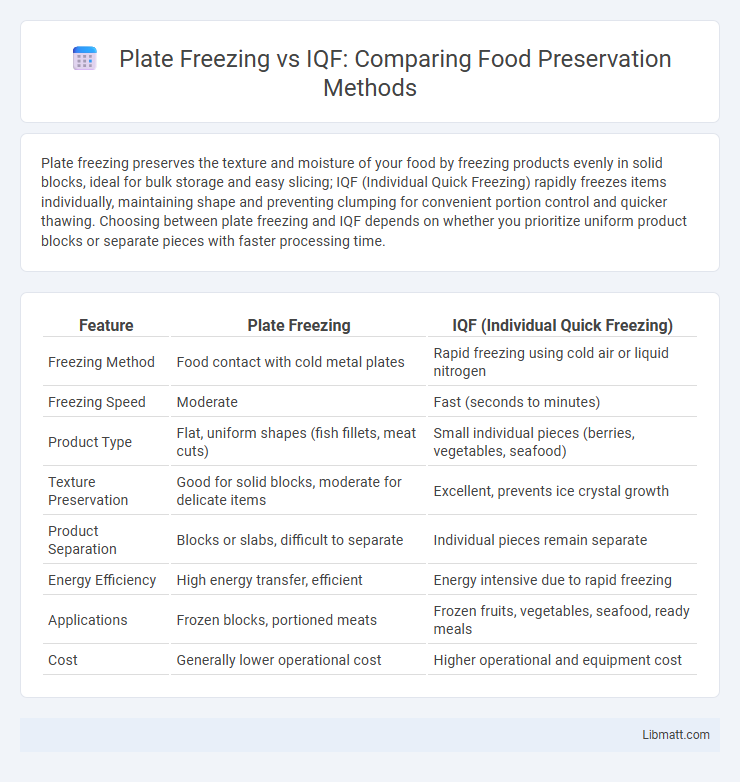

Plate freezing preserves the texture and moisture of your food by freezing products evenly in solid blocks, ideal for bulk storage and easy slicing; IQF (Individual Quick Freezing) rapidly freezes items individually, maintaining shape and preventing clumping for convenient portion control and quicker thawing. Choosing between plate freezing and IQF depends on whether you prioritize uniform product blocks or separate pieces with faster processing time.

Table of Comparison

| Feature | Plate Freezing | IQF (Individual Quick Freezing) |

|---|---|---|

| Freezing Method | Food contact with cold metal plates | Rapid freezing using cold air or liquid nitrogen |

| Freezing Speed | Moderate | Fast (seconds to minutes) |

| Product Type | Flat, uniform shapes (fish fillets, meat cuts) | Small individual pieces (berries, vegetables, seafood) |

| Texture Preservation | Good for solid blocks, moderate for delicate items | Excellent, prevents ice crystal growth |

| Product Separation | Blocks or slabs, difficult to separate | Individual pieces remain separate |

| Energy Efficiency | High energy transfer, efficient | Energy intensive due to rapid freezing |

| Applications | Frozen blocks, portioned meats | Frozen fruits, vegetables, seafood, ready meals |

| Cost | Generally lower operational cost | Higher operational and equipment cost |

Introduction to Plate Freezing and IQF

Plate freezing involves placing products between chilled metal plates, enabling rapid heat transfer for uniform freezing, commonly used for slabs, blocks, and filled products. Individual Quick Freezing (IQF) rapidly freezes small or loose items like fruits, vegetables, and seafood by exposing them to cold air blasts, ensuring product separation and preserving texture and quality. Both methods optimize freezing speed and product integrity tailored for different food types and processing needs.

How Plate Freezing Works

Plate freezing uses metal plates to rapidly freeze products by direct contact, ensuring efficient heat transfer and uniform freezing. The product is placed between chilled plates, which quickly lower the temperature and lock in freshness while minimizing moisture loss. This method optimizes the quality of dense or solid food items, preserving texture and flavor for Your frozen goods.

Understanding IQF (Individual Quick Freezing)

Individual Quick Freezing (IQF) rapidly freezes food items such as fruits, vegetables, and seafood by exposing them to extremely cold air, ensuring each piece is frozen separately. This method preserves texture, flavor, and nutritional value better than Plate Freezing, which freezes food in blocks and may cause clumping. IQF's rapid freezing minimizes ice crystal formation, maintaining product quality and allowing for easy portion control and reduced thawing times.

Key Differences Between Plate Freezing and IQF

Plate freezing uses metal plates to freeze products quickly by direct contact, resulting in uniform freeze and compact blocks ideal for storage. IQF (Individual Quick Freezing) freezes each item separately using cold air blasts, preserving texture and preventing clumping, suitable for items like berries or seafood. Understanding these key differences helps you choose the best freezing method for your product's quality and storage needs.

Speed and Efficiency Comparison

IQF (Individually Quick Frozen) technology offers higher freezing speeds by rapidly freezing products with minimal clumping, which enhances overall processing efficiency in high-volume production lines. Plate freezing, while slower due to conductive freezing through contact plates, provides uniform freezing ideal for flat or block-shaped products, optimizing energy use and reducing thaw drip loss. Choosing between IQF and plate freezing depends on production speed requirements and product type, with IQF excelled in speed and throughput, whereas plate freezing offers precise control and energy efficiency.

Impact on Product Quality and Texture

Plate freezing preserves the integrity of food products by applying uniform cold surfaces, resulting in consistent texture and minimal cellular damage, ideal for delicate items like fish fillets. IQF (Individually Quick Frozen) uses rapid airflow freezing to freeze products separately, preventing clumping and maintaining original shape, which enhances texture for irregularly shaped foods such as berries or shrimp. The choice between plate freezing and IQF directly influences product quality, with plate freezing offering smoother texture and IQF providing better portion control and reduced freezer burn.

Energy Consumption and Operational Costs

Plate freezing typically consumes less energy due to its direct contact method, resulting in efficient heat transfer and lower operational costs for batch processes. IQF (Individual Quick Freezing) uses blast freezing with high-velocity cold air, leading to higher energy consumption but offering flexibility and faster freezing times ideal for variable loads. You can reduce long-term expenses by choosing plate freezing for consistent large batches, while IQF suits smaller, varied production runs despite higher energy demands.

Best Applications for Plate Freezing

Plate freezing is ideal for solid food items requiring uniform freezing and compact storage, such as fish fillets, meat cuts, and bakery products. It excels in preserving product shape and quality by freezing items in stacked trays, making it suitable for bulk processing and efficient space utilization in your cold storage. Compared to IQF, plate freezing is less effective for small or irregularly shaped items that need individual quick freezing to prevent clumping.

Ideal Uses for IQF Technology

IQF (Individually Quick Frozen) technology is ideal for preserving the quality and texture of small, delicate food items such as berries, seafood, and diced vegetables, as it freezes each piece separately to prevent clumping. This method ensures faster freezing times and better retention of flavor, nutrients, and appearance compared to plate freezing, which is better suited for large, flat products like fish fillets or meat slabs. IQF technology is highly beneficial for products requiring easy portion control and minimal thawing time, making it a preferred choice in the food processing industry for frozen ready-to-eat meals and snack items.

Choosing the Right Freezing Method for Your Needs

Selecting the right freezing method depends on your product type, volume, and quality requirements. Plate freezing offers uniform temperature control ideal for flat or block-shaped items, ensuring efficient heat transfer and space-saving storage. IQF (Individual Quick Freezing) preserves texture and flavor by freezing products individually and rapidly, making it suitable for delicate or irregularly shaped items requiring easy portioning.

Plate Freezing vs IQF Infographic

libmatt.com

libmatt.com