Microencapsulation involves enclosing active ingredients within tiny capsules typically ranging from 1 to 1000 micrometers, providing controlled release and protection from environmental factors. Nanoencapsulation offers even smaller particle sizes, usually below 100 nanometers, enhancing bioavailability and targeted delivery, which may improve the effectiveness of Your products in pharmaceuticals, cosmetics, or food industries.

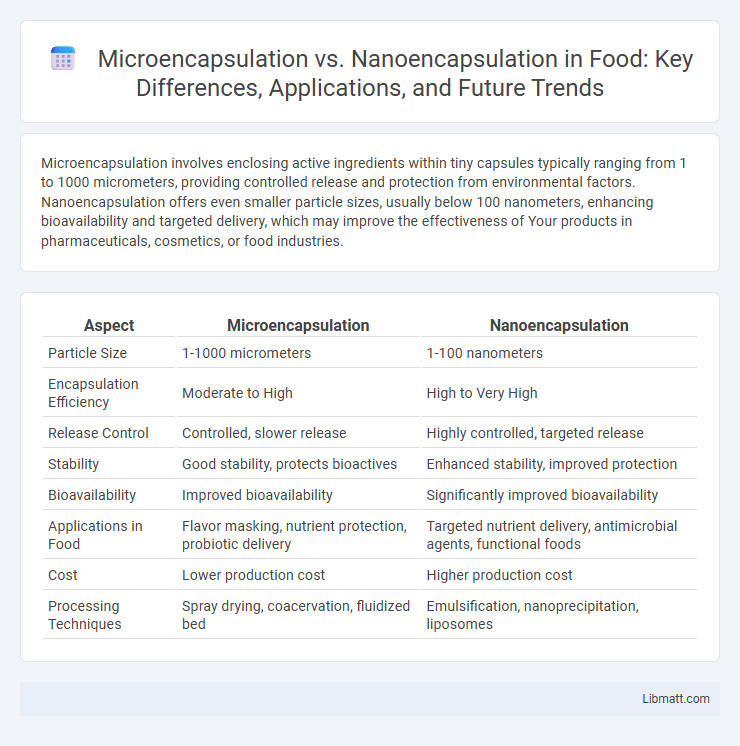

Table of Comparison

| Aspect | Microencapsulation | Nanoencapsulation |

|---|---|---|

| Particle Size | 1-1000 micrometers | 1-100 nanometers |

| Encapsulation Efficiency | Moderate to High | High to Very High |

| Release Control | Controlled, slower release | Highly controlled, targeted release |

| Stability | Good stability, protects bioactives | Enhanced stability, improved protection |

| Bioavailability | Improved bioavailability | Significantly improved bioavailability |

| Applications in Food | Flavor masking, nutrient protection, probiotic delivery | Targeted nutrient delivery, antimicrobial agents, functional foods |

| Cost | Lower production cost | Higher production cost |

| Processing Techniques | Spray drying, coacervation, fluidized bed | Emulsification, nanoprecipitation, liposomes |

Introduction to Microencapsulation and Nanoencapsulation

Microencapsulation and nanoencapsulation involve enveloping active ingredients within protective coatings to enhance stability, control release, and improve bioavailability. Microencapsulation typically produces particles ranging from 1 to 1000 microns, suitable for applications in pharmaceuticals, food, and agriculture. Nanoencapsulation, with particle sizes below 100 nanometers, offers higher surface area and improved cellular absorption, making it ideal for targeted drug delivery and advanced biomedical uses.

Defining Microencapsulation

Microencapsulation is a process that involves enclosing active ingredients within microscopic capsules, typically ranging from 1 to 1000 micrometers in diameter, to protect them from environmental factors and control their release. Unlike nanoencapsulation, which deals with particles under 100 nanometers, microencapsulation offers greater stability for larger molecules and is widely used in pharmaceuticals, food technology, and agriculture. This technique enhances the shelf life, bioavailability, and targeted delivery of sensitive compounds by providing a physical barrier against moisture, oxygen, and light.

Understanding Nanoencapsulation

Nanoencapsulation involves enclosing active ingredients within nanometer-sized carriers, typically ranging from 10 to 1000 nanometers, which enhances bioavailability, targeted delivery, and controlled release. Compared to microencapsulation, nanoencapsulation offers superior penetration and protection of sensitive compounds by improving stability and solubility at the nanoscale. Your formulations can benefit from nanoencapsulation's precise delivery mechanisms, making it ideal for pharmaceuticals, cosmetics, and food applications seeking enhanced efficacy.

Key Differences Between Microencapsulation and Nanoencapsulation

Microencapsulation involves enclosing active ingredients within microscopic particles typically ranging from 1 to 1000 micrometers, whereas nanoencapsulation confines substances within nanoparticles sized between 1 and 100 nanometers, offering enhanced surface area and bioavailability. Key differences include particle size, with nanoencapsulation providing superior cellular uptake and controlled release properties due to its smaller scale. Additionally, nanoencapsulation enables improved stability and targeted delivery in drug delivery systems and food applications compared to conventional microencapsulation techniques.

Core Materials and Encapsulation Techniques

Microencapsulation typically involves encapsulating core materials such as oils, flavors, and pharmaceuticals within micron-sized polymer or lipid shells using techniques like spray drying, coacervation, and fluidized bed coating. Nanoencapsulation targets nanoscale core materials, often enhancing bioavailability of drugs, antioxidants, and nutrients, using methods like nanoprecipitation, emulsification-solvent evaporation, and self-assembly. Both encapsulation processes optimize release profiles and protection of sensitive core materials, but nanoencapsulation offers improved surface area-to-volume ratios enabling more efficient delivery and controlled release at the molecular level.

Advantages of Microencapsulation

Microencapsulation offers advantages such as enhanced protection of active ingredients from environmental factors, controlled release properties, and improved handling and dosing accuracy in pharmaceuticals and food industries. Its larger particle size compared to nanoencapsulation allows for easier production, cost-effectiveness, and reduced risks related to toxicity and regulatory concerns. The technology is widely used for flavor masking, stability enhancement, and targeted delivery in various applications including nutraceuticals and agriculture.

Benefits of Nanoencapsulation

Nanoencapsulation offers enhanced bioavailability and targeted delivery of active compounds due to its ultra-small particle size, which improves cellular uptake and absorption. It provides superior protection of sensitive ingredients from environmental degradation, ensuring sustained release and increased stability. This technology enables precise control over drug or nutrient release profiles, boosting therapeutic efficacy and reducing side effects compared to microencapsulation.

Applications in Pharmaceuticals and Food Industry

Microencapsulation and nanoencapsulation enhance targeted drug delivery by improving bioavailability and controlled release in pharmaceuticals, with microcapsules commonly used for sustained-release formulations and nanoparticles designed for precision therapy and improved cellular uptake. In the food industry, microencapsulation protects sensitive nutrients and flavors from degradation while nanoencapsulation offers greater solubility and bioaccessibility of vitamins and antioxidants, supporting functional food development. Your choice between micro- and nanoencapsulation depends on the desired release profile, stability, and application method within these industries.

Challenges and Limitations of Each Method

Microencapsulation faces challenges such as limited control over particle size, which can impact release rates and bioavailability, along with potential issues in maintaining stability during processing. Nanoencapsulation, while offering enhanced bioavailability and targeted delivery, encounters limitations including complex manufacturing processes, higher costs, and potential toxicity concerns due to the ultra-small size of particles. Your choice between these methods should consider the trade-offs between scalability, control, and application-specific safety requirements.

Future Trends in Encapsulation Technologies

Future trends in encapsulation technologies emphasize enhanced control over release profiles and increased bioavailability through nanoencapsulation, leveraging smaller particle sizes for improved cellular uptake. Microencapsulation remains crucial for protecting sensitive ingredients and enabling targeted delivery in food and pharmaceuticals, with advancements focusing on sustainable and biodegradable materials. Integration of smart stimuli-responsive systems and scalable manufacturing processes will drive innovation in both micro- and nanoencapsulation, fostering more efficient and precise applications across industries.

microencapsulation vs nanoencapsulation Infographic

libmatt.com

libmatt.com