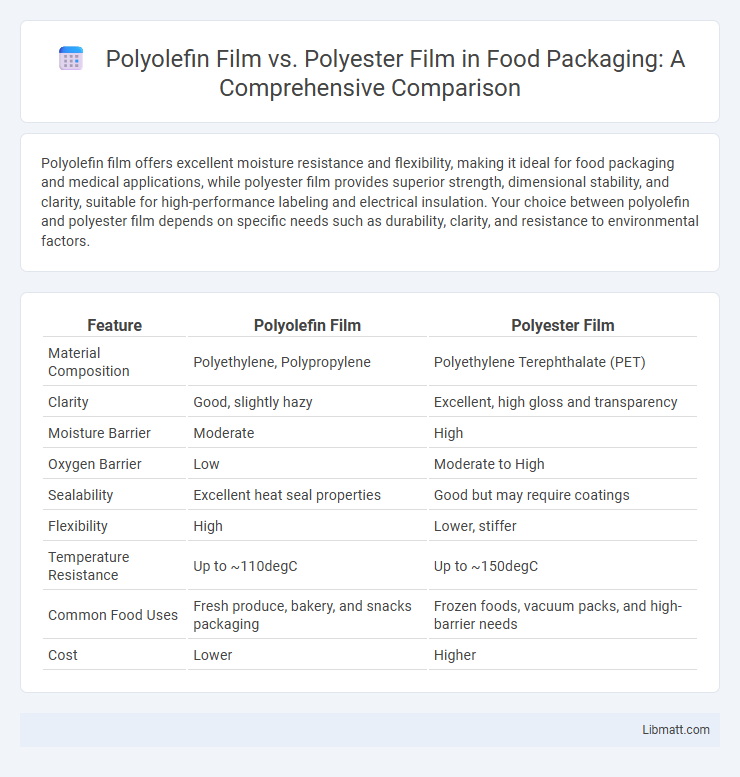

Polyolefin film offers excellent moisture resistance and flexibility, making it ideal for food packaging and medical applications, while polyester film provides superior strength, dimensional stability, and clarity, suitable for high-performance labeling and electrical insulation. Your choice between polyolefin and polyester film depends on specific needs such as durability, clarity, and resistance to environmental factors.

Table of Comparison

| Feature | Polyolefin Film | Polyester Film |

|---|---|---|

| Material Composition | Polyethylene, Polypropylene | Polyethylene Terephthalate (PET) |

| Clarity | Good, slightly hazy | Excellent, high gloss and transparency |

| Moisture Barrier | Moderate | High |

| Oxygen Barrier | Low | Moderate to High |

| Sealability | Excellent heat seal properties | Good but may require coatings |

| Flexibility | High | Lower, stiffer |

| Temperature Resistance | Up to ~110degC | Up to ~150degC |

| Common Food Uses | Fresh produce, bakery, and snacks packaging | Frozen foods, vacuum packs, and high-barrier needs |

| Cost | Lower | Higher |

Introduction to Polyolefin and Polyester Films

Polyolefin films, made from polymers like polyethylene and polypropylene, offer flexibility, excellent moisture barrier properties, and cost-effectiveness, making them ideal for packaging applications. Polyester films, primarily polyethylene terephthalate (PET), provide superior mechanical strength, thermal stability, and chemical resistance, often used in industrial and electrical industries. Your choice between polyolefin and polyester film depends on specific requirements such as durability, clarity, and environmental resistance.

Chemical Structure Comparison

Polyolefin film consists primarily of long chains of polyethylene or polypropylene, featuring a saturated hydrocarbon backbone that imparts high chemical resistance and flexibility. Polyester film, typically made from polyethylene terephthalate (PET), contains aromatic rings and ester functional groups, resulting in superior tensile strength and thermal stability. The chemical structure differences influence their barrier properties, with polyester films offering better moisture and gas resistance compared to the more permeable polyolefin films.

Key Physical Properties

Polyolefin film exhibits excellent moisture resistance, high clarity, and superior flexibility, making it ideal for packaging applications requiring conformability and sealing performance. Polyester film offers exceptional tensile strength, dimensional stability, and resistance to chemicals and UV radiation, suitable for durable, high-temperature environments. Both films vary significantly in their thermal resistance, with polyester films typically withstanding higher temperatures than polyolefin films.

Mechanical Strength and Durability

Polyolefin film offers excellent impact resistance and flexibility, making it highly durable in applications requiring toughness and stretchability. Polyester film exhibits superior tensile strength and dimensional stability, ensuring mechanical durability under high stress and temperature conditions. Your choice depends on whether enhanced flexibility or long-term strength under thermal load is the priority.

Optical Clarity and Appearance

Polyester film offers superior optical clarity with high transparency and excellent gloss, making it ideal for applications requiring sharp, bright visuals. Polyolefin film has a slightly lower clarity and haziness, but provides a softer, matte appearance preferred for specific packaging aesthetics. Your choice between these films depends on whether you prioritize crystal-clear visuals (polyester) or a subtle, muted look (polyolefin).

Barrier Properties: Moisture, Gas, and Odor

Polyolefin film offers moderate moisture barrier properties but generally has lower gas and odor barrier performance compared to polyester film. Polyester film excels in providing superior barrier resistance against moisture, gases like oxygen and carbon dioxide, and odor retention, making it ideal for packaging sensitive products. Your choice depends on the required protection level, with polyester film being preferable for applications demanding high barrier capabilities.

Printability and Surface Treatment

Polyolefin film typically requires surface treatment such as corona or plasma to enhance its low surface energy for better printability, allowing inks and coatings to adhere effectively. Polyester film has inherently higher surface energy, offering superior print quality without extensive surface treatment, making it ideal for high-resolution graphics and durability. Choosing the right film depends on your print application, where polyolefin suits cost-effective projects and polyester excels in premium, high-performance prints.

Common Applications and Uses

Polyolefin film is widely used in food packaging, medical device packaging, and shrink wrapping due to its excellent moisture resistance and flexibility. Polyester film is favored in electrical insulation, solar panel protection, and graphic arts for its superior tensile strength, clarity, and dimensional stability. Your choice depends on specific application needs such as durability, clarity, or barrier properties.

Environmental Impact and Recyclability

Polyolefin film offers a lower environmental impact due to its easier recyclability and biodegradability compared to polyester film, which is derived from petroleum-based resins and often requires specialized recycling processes. Polyolefin films decompose more rapidly and emit fewer greenhouse gases during production, enhancing their eco-friendliness. Polyester films, while durable and recyclable, typically face challenges in waste management due to their longer degradation time and reliance on energy-intensive recycling infrastructures.

Cost Considerations and Market Trends

Polyolefin film generally offers a lower-cost alternative to polyester film, making it attractive for budget-sensitive packaging applications without compromising flexibility and sealability. Market trends indicate a growing demand for polyolefin due to its recyclability and environmental benefits, driving wider adoption in sustainable packaging solutions. If your priority is cost-efficiency aligned with eco-friendly materials, polyolefin film presents a more economically viable option compared to polyester film.

polyolefin film vs polyester film Infographic

libmatt.com

libmatt.com