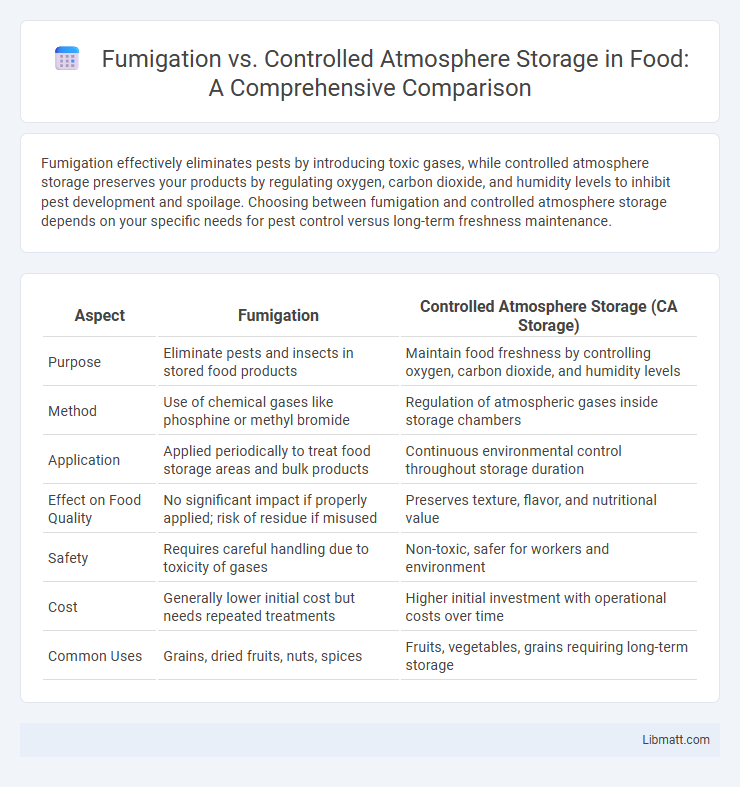

Fumigation effectively eliminates pests by introducing toxic gases, while controlled atmosphere storage preserves your products by regulating oxygen, carbon dioxide, and humidity levels to inhibit pest development and spoilage. Choosing between fumigation and controlled atmosphere storage depends on your specific needs for pest control versus long-term freshness maintenance.

Table of Comparison

| Aspect | Fumigation | Controlled Atmosphere Storage (CA Storage) |

|---|---|---|

| Purpose | Eliminate pests and insects in stored food products | Maintain food freshness by controlling oxygen, carbon dioxide, and humidity levels |

| Method | Use of chemical gases like phosphine or methyl bromide | Regulation of atmospheric gases inside storage chambers |

| Application | Applied periodically to treat food storage areas and bulk products | Continuous environmental control throughout storage duration |

| Effect on Food Quality | No significant impact if properly applied; risk of residue if misused | Preserves texture, flavor, and nutritional value |

| Safety | Requires careful handling due to toxicity of gases | Non-toxic, safer for workers and environment |

| Cost | Generally lower initial cost but needs repeated treatments | Higher initial investment with operational costs over time |

| Common Uses | Grains, dried fruits, nuts, spices | Fruits, vegetables, grains requiring long-term storage |

Introduction to Grain Preservation Methods

Fumigation and controlled atmosphere storage represent pivotal grain preservation methods designed to safeguard against insect infestation and microbial spoilage. Fumigation involves the application of chemical gases such as phosphine or methyl bromide to eliminate pests, ensuring immediate disinfestation. Controlled atmosphere storage modifies oxygen, carbon dioxide, and nitrogen levels within sealed environments, creating inhospitable conditions for pests while maintaining grain quality over extended periods.

Understanding Fumigation: Process and Purpose

Fumigation involves the application of chemical gases such as phosphine or methyl bromide to eliminate pests in stored products, ensuring effective pest control and safeguarding crop quality. This process penetrates stored commodities and packaging to eradicate insects, molds, and fungi, preventing contamination and loss. Your choice between fumigation and controlled atmosphere storage depends on factors like pest type, commodity sensitivity, and safety considerations.

What is Controlled Atmosphere Storage?

Controlled Atmosphere Storage is a preservation technique that regulates oxygen, carbon dioxide, and humidity levels to extend the shelf life of fruits and vegetables by slowing their respiration and delaying ripening. Unlike fumigation, which uses chemical gases to eliminate pests and pathogens, controlled atmosphere storage creates an optimal environment to maintain freshness naturally without chemical residues. This method is widely used for apples, pears, and leafy greens, ensuring quality preservation during long-term storage.

Key Differences Between Fumigation and Controlled Atmosphere Storage

Fumigation involves the application of chemical gases to eliminate pests and pathogens in stored products, while Controlled Atmosphere Storage regulates oxygen, carbon dioxide, and nitrogen levels to inhibit spoilage and extend shelf life. Fumigation is primarily a pest control method used intermittently, whereas Controlled Atmosphere Storage is a continuous technique maintaining specific gas compositions for long-term preservation. The chemical residues from fumigation may pose health risks, whereas Controlled Atmosphere Storage is a non-chemical approach that maintains product quality and freshness without toxic residues.

Effectiveness in Pest Control

Fumigation provides rapid and thorough pest elimination by penetrating stored products and confined spaces with gases like phosphine or methyl bromide, ensuring immediate pest mortality. Controlled Atmosphere Storage maintains low oxygen and high carbon dioxide levels to suppress pest metabolism and reproduction, offering prolonged pest management without chemical residues. While fumigation achieves quick disinfestation, Controlled Atmosphere Storage delivers safer, residue-free pest control optimal for long-term storage.

Impact on Grain Quality and Safety

Fumigation effectively eliminates insect pests but can leave chemical residues that may affect grain safety and quality, potentially altering taste and posing health risks. Controlled atmosphere storage maintains grain quality by using low oxygen and high carbon dioxide levels to suppress pests without chemical use, preserving nutritional value and flavor. This method ensures safer long-term storage while minimizing chemical residues, making it more favorable for maintaining grain integrity and consumer safety.

Environmental and Health Considerations

Fumigation involves the use of chemical pesticides like methyl bromide, which pose significant risks to human health and contribute to environmental pollution and ozone depletion. Controlled Atmosphere Storage relies on manipulating oxygen, carbon dioxide, and nitrogen levels, offering a non-toxic, environmentally friendly alternative that minimizes chemical residues. This method reduces health hazards for workers and consumers while ensuring produce preservation with minimal ecological impact.

Cost Comparison: Fumigation vs Controlled Atmosphere Storage

Fumigation typically incurs lower upfront costs but may require repeated treatments and specialized safety measures, increasing overall expenses. Controlled Atmosphere Storage involves higher initial investment due to advanced technology and monitoring systems but offers longer-term savings by reducing spoilage and maintaining product quality. Your choice depends on balancing immediate budget constraints with long-term storage goals and cost efficiency.

Regulatory Guidelines and Compliance

Fumigation and Controlled Atmosphere Storage both require strict adherence to regulatory guidelines to ensure safety and efficacy. Regulatory agencies such as the EPA and USDA enforce compliance with chemical usage limits for fumigants, while Controlled Atmosphere Storage must meet standards for atmospheric gas concentrations and monitoring protocols. Understanding these regulations helps ensure your storage practices prevent pest infestations without compromising product quality or legal compliance.

Choosing the Right Method for Your Storage Needs

Choosing the right method for your storage needs depends on factors such as the type of commodity, duration of storage, and pest control requirements. Fumigation offers immediate pest eradication by using chemical gases, while Controlled Atmosphere Storage relies on modifying oxygen, carbon dioxide, and nitrogen levels to suppress pests and extend shelf life without chemical residues. Evaluating your storage environment and safety considerations ensures you select the most effective and sustainable solution for protecting your products.

Fumigation vs Controlled Atmosphere Storage Infographic

libmatt.com

libmatt.com