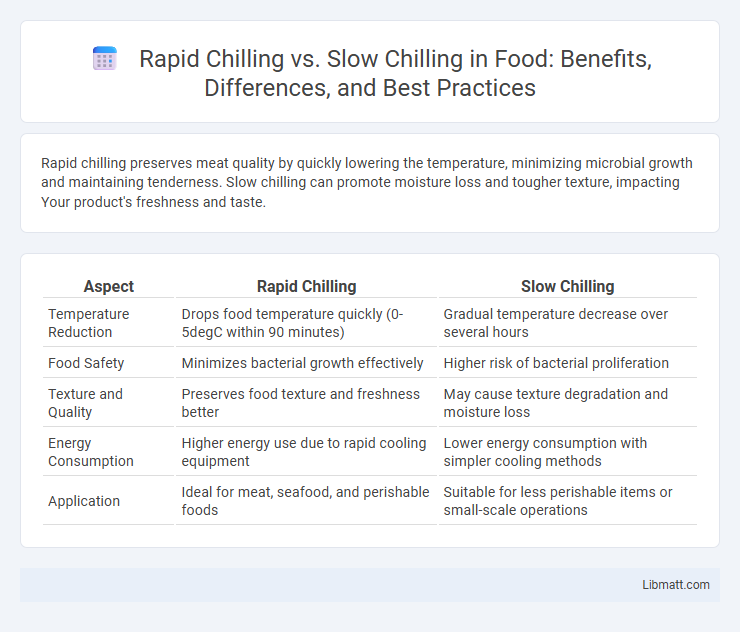

Rapid chilling preserves meat quality by quickly lowering the temperature, minimizing microbial growth and maintaining tenderness. Slow chilling can promote moisture loss and tougher texture, impacting Your product's freshness and taste.

Table of Comparison

| Aspect | Rapid Chilling | Slow Chilling |

|---|---|---|

| Temperature Reduction | Drops food temperature quickly (0-5degC within 90 minutes) | Gradual temperature decrease over several hours |

| Food Safety | Minimizes bacterial growth effectively | Higher risk of bacterial proliferation |

| Texture and Quality | Preserves food texture and freshness better | May cause texture degradation and moisture loss |

| Energy Consumption | Higher energy use due to rapid cooling equipment | Lower energy consumption with simpler cooling methods |

| Application | Ideal for meat, seafood, and perishable foods | Suitable for less perishable items or small-scale operations |

Introduction to Chilling Methods

Rapid chilling quickly lowers the temperature of perishable products to inhibit bacterial growth and preserve freshness, making it ideal for meat, seafood, and dairy. Slow chilling gradually reduces temperature, which can be beneficial for some fruits and vegetables to maintain texture and flavor but increases the risk of microbial activity. Your choice between rapid and slow chilling depends on the specific product requirements and desired shelf life.

What is Rapid Chilling?

Rapid chilling is a preservation process that quickly lowers the temperature of food products, especially meat and seafood, to inhibit bacterial growth and maintain freshness. This method reduces the time food spends in the temperature danger zone (40degF to 140degF), thereby minimizing spoilage and extending shelf life. You benefit from improved food safety and quality by choosing rapid chilling over slow chilling techniques.

What is Slow Chilling?

Slow chilling is a food preservation method that gradually reduces the temperature of perishable products, typically to just above freezing, to maintain quality and extend shelf life. This process minimizes moisture loss and prevents thermal shock, preserving texture, flavor, and nutritional value. Slow chilling is often used for delicate items like fresh meat, seafood, and fruits to ensure optimal freshness and safety.

Key Differences Between Rapid and Slow Chilling

Rapid chilling involves quickly lowering the temperature of a product, typically meat or produce, to inhibit microbial growth and preserve freshness, whereas slow chilling gradually reduces temperature over a longer period, which may allow for enzyme activity and moisture redistribution. Key differences include the impact on texture and shelf life; rapid chilling maintains firmness and extends shelf life by minimizing bacterial proliferation, while slow chilling can lead to increased drip loss and potential textural changes due to enzymatic reactions. Energy consumption also varies, with rapid chilling requiring higher immediate energy input but improving overall product quality and safety compared to the more energy-efficient but slower process.

Effects on Product Quality

Rapid chilling preserves product quality by reducing microbial growth and minimizing enzymatic activity, which helps maintain freshness, texture, and color. Slow chilling often leads to increased moisture loss and greater protein denaturation, resulting in reduced tenderness and flavor. By implementing rapid chilling, you ensure superior product quality and extended shelf life.

Impact on Microbial Safety

Rapid chilling significantly reduces microbial growth by quickly lowering the temperature of food products, thereby inhibiting the proliferation of pathogenic bacteria such as Salmonella and Listeria. Slow chilling allows for extended periods within the danger zone (5degC to 60degC), increasing the risk of microbial contamination and toxin production. Maintaining rapid chilling protocols is essential for ensuring enhanced microbial safety and extending the shelf life of perishable foods.

Energy Consumption and Cost Analysis

Rapid chilling consumes significantly more energy initially due to powerful refrigeration systems but reduces overall operational costs by minimizing spoilage and preserving product quality longer. Slow chilling has lower immediate energy usage but often leads to higher cumulative expenses from increased energy consumption over extended cooling periods and greater product degradation. Your choice between rapid and slow chilling impacts both energy efficiency and long-term cost management in food processing.

Applications in Food Processing Industries

Rapid chilling in food processing industries significantly enhances product quality by minimizing microbial growth and preserving freshness, especially in meat and seafood sectors. Slow chilling is traditionally used for products like dairy and certain fruits, where gradual temperature reduction helps maintain texture and flavor integrity. Optimizing chilling methods based on product type improves shelf life, reduces spoilage, and ensures compliance with food safety standards.

Environmental Considerations

Rapid chilling significantly reduces energy consumption by shortening cooling time, thereby decreasing greenhouse gas emissions compared to slow chilling methods. Slow chilling often requires prolonged refrigeration, leading to higher electricity use and increased carbon footprint from extended machinery operation. Optimizing your cooling process by choosing rapid chilling can enhance sustainability and reduce environmental impact in food storage and processing.

Choosing the Right Chilling Method

Choosing the right chilling method depends on the type of meat and desired quality outcomes. Rapid chilling preserves meat freshness by quickly reducing temperature, minimizing bacterial growth and moisture loss, ideal for high-value cuts. Slow chilling, while energy-efficient, can result in increased drip loss and microbial activity, making it suitable for less delicate products where extended shelf life is not critical.

rapid chilling vs slow chilling Infographic

libmatt.com

libmatt.com