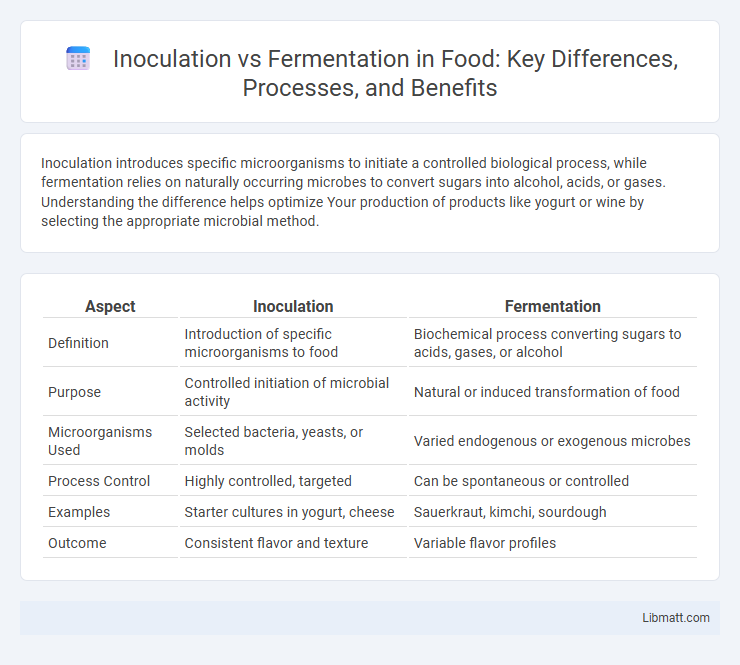

Inoculation introduces specific microorganisms to initiate a controlled biological process, while fermentation relies on naturally occurring microbes to convert sugars into alcohol, acids, or gases. Understanding the difference helps optimize Your production of products like yogurt or wine by selecting the appropriate microbial method.

Table of Comparison

| Aspect | Inoculation | Fermentation |

|---|---|---|

| Definition | Introduction of specific microorganisms to food | Biochemical process converting sugars to acids, gases, or alcohol |

| Purpose | Controlled initiation of microbial activity | Natural or induced transformation of food |

| Microorganisms Used | Selected bacteria, yeasts, or molds | Varied endogenous or exogenous microbes |

| Process Control | Highly controlled, targeted | Can be spontaneous or controlled |

| Examples | Starter cultures in yogurt, cheese | Sauerkraut, kimchi, sourdough |

| Outcome | Consistent flavor and texture | Variable flavor profiles |

Introduction to Inoculation and Fermentation

Inoculation involves introducing specific microorganisms, such as bacteria or yeast, into a substrate to initiate controlled biological processes. Fermentation is a metabolic process where these microorganisms convert sugars and other compounds into acids, gases, or alcohol under anaerobic conditions. Both techniques play crucial roles in food production, biotechnology, and pharmaceuticals, with inoculation serving as the precise starting point for fermentation-driven transformations.

Defining Inoculation in Food and Beverage Production

In food and beverage production, inoculation refers to the intentional introduction of specific microorganisms such as bacteria, yeast, or mold to initiate or control fermentation processes. This practice ensures consistent product quality by promoting the growth of desirable microbial strains that influence flavor, texture, and safety. Controlled inoculation contrasts with spontaneous fermentation, where indigenous microbes naturally present in the environment drive the process without targeted intervention.

Understanding the Fermentation Process

Understanding the fermentation process involves recognizing the role of microbial inoculation, where specific strains of bacteria or yeast are introduced to initiate and control fermentation. This controlled inoculation ensures consistent flavor development, safety, and efficiency, contrasting with spontaneous fermentation that relies on naturally occurring microbes. Your choice between inoculation and natural fermentation impacts product quality, fermentation duration, and microbial stability.

Key Differences Between Inoculation and Fermentation

Inoculation involves the intentional introduction of specific microorganisms to initiate a controlled biological process, while fermentation is the metabolic activity carried out by these microorganisms to convert substrates into desired products such as alcohol, acids, or gases. Inoculation is a precise step often used to start fermentation, ensuring the selection of beneficial strains, whereas fermentation encompasses the entire biochemical transformation driven by microbial activity. The key difference lies in inoculation being the method of introducing microbes, and fermentation being the resulting metabolic process that produces food, beverages, or biofuels.

The Role of Microorganisms in Inoculation and Fermentation

Microorganisms play a crucial role in both inoculation and fermentation processes by initiating and sustaining biochemical transformations. In inoculation, specific strains of bacteria, yeast, or molds are deliberately introduced to jumpstart desired microbial activity, ensuring controlled growth and metabolic outcomes. Fermentation relies on these microbes to convert substrates like sugars into valuable products such as alcohol, acids, or gases, driving flavor development, preservation, and nutritional enhancements in various foods and beverages.

Applications of Inoculation Across Industries

Inoculation plays a critical role in industries such as agriculture, pharmaceuticals, and food production by introducing specific microorganisms to promote desired biological processes. In agriculture, inoculation enhances soil fertility and crop yields through nitrogen-fixing bacteria. Your products in biotechnology and dairy manufacturing benefit from precise inoculation techniques that ensure consistency and safety during fermentation and microbial growth.

Common Fermentation Techniques and Their Uses

Common fermentation techniques include lactic acid fermentation, used for producing yogurt and sauerkraut, and alcoholic fermentation, essential for brewing beer and winemaking. Inoculation involves introducing specific microorganisms, such as yeast or bacteria, to initiate fermentation, ensuring consistent product quality. Understanding these methods allows you to optimize fermentation processes for diverse food and beverage applications.

Benefits of Controlled Inoculation in Fermentation

Controlled inoculation in fermentation enhances product consistency by introducing specific microbial strains, reducing the risk of contamination and spoilage. This method accelerates fermentation time and improves flavor profiles by optimizing metabolic activity. It also allows precise control over fermentation parameters, leading to higher quality and safety in fermented foods and beverages.

Factors Influencing Successful Fermentation and Inoculation

Successful fermentation relies on factors such as temperature control, pH levels, and the quality of microbial strains used for inoculation. Precise inoculation introduces specific beneficial bacteria or yeasts to initiate and steer fermentation, enhancing consistency and product quality. Environmental conditions, substrate composition, and inoculum size critically influence microbial activity, ensuring optimal fermentation outcomes.

Future Trends in Inoculation and Fermentation Technology

Emerging trends in inoculation and fermentation technology emphasize precision microbiome engineering and automation to enhance product consistency and scalability in food and pharmaceutical industries. Advanced metagenomic tools and AI-driven bioprocess optimization are accelerating the development of bespoke microbial consortia tailored for specific fermentation outcomes, improving flavor profiles, yield, and functional properties. Integration of real-time sensors and IoT platforms is streamlining process control, reducing contamination risks, and enabling adaptive fermentation strategies aligned with circular bioeconomy principles.

inoculation vs fermentation Infographic

libmatt.com

libmatt.com