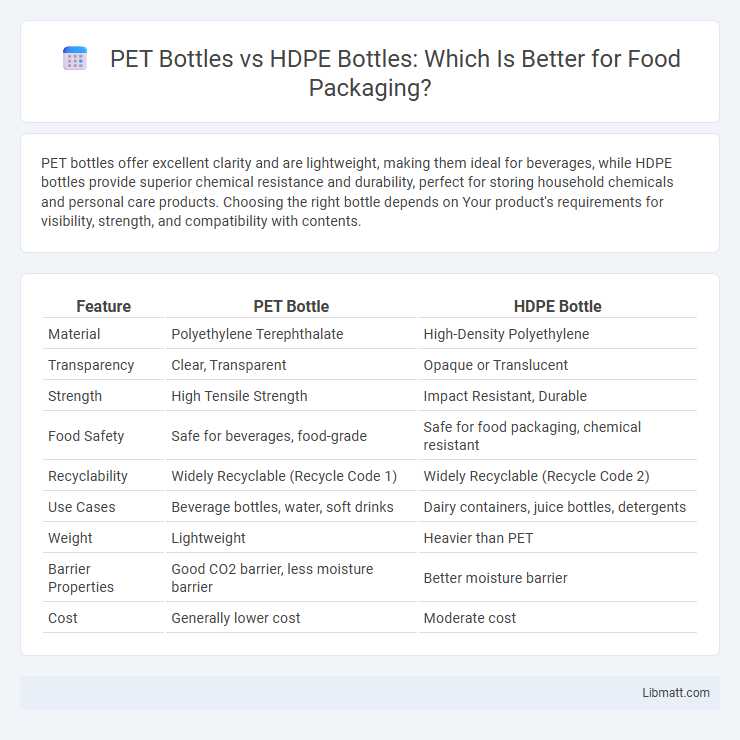

PET bottles offer excellent clarity and are lightweight, making them ideal for beverages, while HDPE bottles provide superior chemical resistance and durability, perfect for storing household chemicals and personal care products. Choosing the right bottle depends on Your product's requirements for visibility, strength, and compatibility with contents.

Table of Comparison

| Feature | PET Bottle | HDPE Bottle |

|---|---|---|

| Material | Polyethylene Terephthalate | High-Density Polyethylene |

| Transparency | Clear, Transparent | Opaque or Translucent |

| Strength | High Tensile Strength | Impact Resistant, Durable |

| Food Safety | Safe for beverages, food-grade | Safe for food packaging, chemical resistant |

| Recyclability | Widely Recyclable (Recycle Code 1) | Widely Recyclable (Recycle Code 2) |

| Use Cases | Beverage bottles, water, soft drinks | Dairy containers, juice bottles, detergents |

| Weight | Lightweight | Heavier than PET |

| Barrier Properties | Good CO2 barrier, less moisture barrier | Better moisture barrier |

| Cost | Generally lower cost | Moderate cost |

Introduction to PET and HDPE Bottles

PET bottles are made from polyethylene terephthalate, known for their clarity, lightweight structure, and high strength, making them ideal for beverage containers. HDPE bottles, composed of high-density polyethylene, offer excellent chemical resistance, durability, and are commonly used for household chemicals and milk containers. Your choice between PET and HDPE bottles depends on the required transparency, strength, and chemical resistance for your specific packaging needs.

Material Composition and Properties

PET bottles are composed of polyethylene terephthalate, a lightweight, transparent polymer known for its excellent gas barrier properties and high tensile strength, making it ideal for carbonated beverage packaging. HDPE bottles consist of high-density polyethylene, a more opaque, flexible material with superior chemical resistance and impact strength, commonly used for dairy products and household chemicals. The distinct molecular structures influence recyclability and durability, with PET offering clearer product visibility and HDPE providing better moisture barrier performance.

Manufacturing Processes

PET bottles are produced through injection molding followed by stretch blow molding, which ensures clarity, strength, and lightweight properties ideal for carbonated beverages. HDPE bottles utilize injection molding or extrusion blow molding techniques, offering excellent chemical resistance and flexibility, commonly used for opaque containers like milk jugs and detergent bottles. The manufacturing process for PET involves precise temperature control to achieve biaxial orientation, whereas HDPE molding focuses on material flow to maintain durability and impact resistance.

Environmental Impact and Sustainability

PET bottles offer higher recyclability rates and are commonly processed into new packaging, reducing landfill waste. HDPE bottles, while slightly less clear, are more durable and have a lower carbon footprint during production, contributing to long-term sustainability. Optimizing Your choice of bottle material can significantly influence environmental impact and resource conservation.

Durability and Strength Comparison

PET bottles exhibit superior clarity and tensile strength, making them highly resistant to impact and less prone to cracking under pressure. HDPE bottles offer excellent chemical resistance and are more flexible, which enhances their durability against bending and environmental stress. While PET bottles excel in maintaining shape and rigidity, HDPE bottles provide better performance in applications requiring shock absorption and resistance to harsh chemicals.

Applications and Common Uses

PET bottles are widely used for packaging carbonated beverages, water, and food products due to their clarity, strength, and lightweight properties. HDPE bottles are common in packaging household cleaners, detergents, and personal care products because of their chemical resistance and durability. Your choice between PET and HDPE bottles should consider the specific application requirements, such as product compatibility and shelf life.

Recyclability and Waste Management

PET bottles exhibit higher recyclability due to their widespread acceptance in curbside recycling programs and efficient processing into fibers, containers, and packaging materials. HDPE bottles are also recyclable but often face challenges in sorting and contamination, which can reduce recycling rates and material quality. Effective waste management systems prioritize PET bottle recycling for circular economy benefits, while innovations aim to improve HDPE bottle recovery and reuse potential.

Cost Considerations

PET bottles generally cost more than HDPE bottles due to higher raw material prices and more complex manufacturing processes, impacting your budget for large-scale production. HDPE bottles offer a cost-effective alternative with lower material and production expenses while maintaining durability and chemical resistance. Choosing between PET and HDPE bottles depends on balancing cost considerations with product requirements and brand positioning.

Safety and Health Implications

PET bottles offer superior resistance to leaching chemicals, making them safer for storing beverages and reducing health risks associated with BPA and phthalate exposure. HDPE bottles, while durable and less likely to crack, can sometimes release potentially harmful additives under high heat or prolonged storage conditions. Both materials require proper handling and recycling to minimize environmental health impacts and ensure consumer safety.

Choosing the Right Bottle for Your Needs

PET bottles offer superior clarity, lightweight design, and excellent gas barrier properties, making them ideal for beverages and food products requiring freshness and visibility. HDPE bottles provide greater chemical resistance, durability, and flexibility, suitable for household chemicals, cleaning products, and cosmetics. Selecting the right bottle depends on product compatibility, storage conditions, and desired shelf life to ensure optimal performance and safety.

PET bottle vs HDPE bottle Infographic

libmatt.com

libmatt.com