Rack drying offers more uniform airflow around each item, making it ideal for delicate or small batches that require gentle handling, while tunnel drying excels in high-volume production with continuous processing and faster drying times. Your choice depends on whether precision and care or speed and capacity are the priority in your drying process.

Table of Comparison

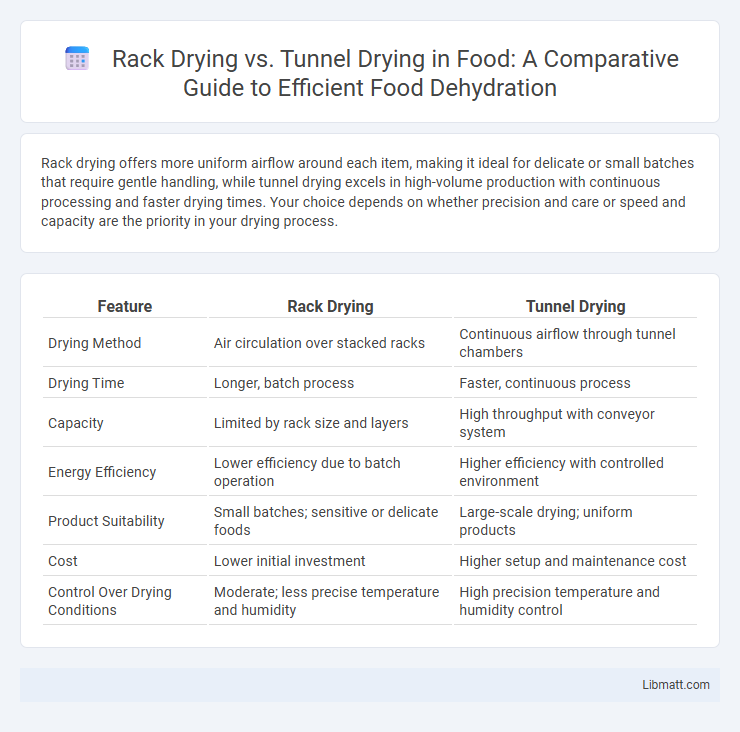

| Feature | Rack Drying | Tunnel Drying |

|---|---|---|

| Drying Method | Air circulation over stacked racks | Continuous airflow through tunnel chambers |

| Drying Time | Longer, batch process | Faster, continuous process |

| Capacity | Limited by rack size and layers | High throughput with conveyor system |

| Energy Efficiency | Lower efficiency due to batch operation | Higher efficiency with controlled environment |

| Product Suitability | Small batches; sensitive or delicate foods | Large-scale drying; uniform products |

| Cost | Lower initial investment | Higher setup and maintenance cost |

| Control Over Drying Conditions | Moderate; less precise temperature and humidity | High precision temperature and humidity control |

Introduction to Rack Drying and Tunnel Drying

Rack drying involves placing items on multiple shelves or racks, allowing air to circulate freely around each product for uniform moisture removal, commonly used in industries such as food processing and pharmaceuticals. Tunnel drying employs a continuous conveyor system that moves products through a controlled environment, enabling high-capacity drying with consistent temperature and humidity levels, often utilized in large-scale manufacturing. Both methods optimize drying efficiency but differ significantly in batch size, processing speed, and application scope.

Core Principles of Rack Drying

Rack drying relies on air circulation around individual trays or racks to remove moisture, optimizing drying efficiency for small or delicate batches. This method provides uniform drying by exposing each product layer to controlled airflow and temperature, preserving quality and preventing over-drying. Your choice of rack drying can enhance precision in moisture content, making it ideal for sensitive materials requiring gentle handling.

Core Principles of Tunnel Drying

Tunnel drying operates by moving products through a controlled heated air flow within a long, enclosed chamber, ensuring uniform moisture removal through constant temperature and airflow regulation. This method enhances drying efficiency by maintaining consistent environmental conditions, reducing drying time compared to rack drying. Your choice of tunnel drying can improve product quality and throughput due to its ability to handle larger volumes with precise control over drying parameters.

Equipment and Setup Requirements

Rack drying requires individual racks or trays to hold products, making it suitable for small to medium-scale operations with flexible and modular setups. Tunnel drying involves a continuous conveyor system within an enclosed tunnel, necessitating more extensive infrastructure and higher initial investment, ideal for large-scale, uniform drying processes. Equipment for tunnel drying includes fans, heaters, and sensors integrated for precise control, while rack drying setups rely on simpler airflow systems and manual loading.

Energy Consumption Comparison

Rack drying consumes less energy by allowing air to circulate naturally around stored items, making it more efficient for small-scale or batch drying processes. Tunnel drying requires a continuous airflow system and higher temperatures, resulting in significantly increased energy consumption suited for large-scale industrial operations. Understanding your production volume helps in choosing the drying method that optimizes energy use and reduces operational costs.

Drying Time and Efficiency

Rack drying typically requires longer drying time due to limited airflow and heat distribution, resulting in lower efficiency for large-scale operations. Tunnel drying accelerates the process by using continuous airflow and controlled temperatures, significantly reducing drying time and increasing energy efficiency. Optimizing your drying method between rack and tunnel can directly impact productivity and operational costs.

Impact on Product Quality

Rack drying preserves product quality by ensuring even airflow and gentle handling, reducing the risk of physical damage and nutrient loss. Tunnel drying offers faster moisture removal but may cause uneven drying and heat stress, potentially compromising texture and nutritional value. Choosing the appropriate drying method directly influences the retention of essential qualities like color, flavor, and bioactive compounds in the final product.

Cost Analysis: Rack vs Tunnel Drying

Rack drying incurs lower initial capital investment and reduced maintenance expenses compared to tunnel drying, making it cost-effective for small to medium-scale operations. Tunnel drying demands higher energy consumption and operational costs due to continuous processing and larger infrastructure. Evaluating production volume and energy efficiency is crucial for determining the most economical choice between rack and tunnel drying systems.

Suitable Applications for Each Method

Rack drying suits small to medium-sized batches of delicate or irregularly shaped items, allowing precise air circulation around each piece for uniform moisture removal. Tunnel drying is ideal for large-scale, continuous production processes involving bulk materials with consistent shapes and sizes, offering higher throughput and efficiency. Your choice depends on the volume and nature of the product, with rack drying favoring customization and tunnel drying emphasizing speed and capacity.

Choosing the Right Drying Method

Selecting the optimal drying method depends on product type, volume, and drying time requirements; rack drying suits small batches needing gentle handling, while tunnel drying excels in large-scale, continuous operations with consistent airflow. Rack dryers offer precise control for delicate items but have lower throughput compared to tunnel dryers, which deliver faster, uniform drying ideal for mass production. Evaluating energy efficiency, space availability, and desired moisture content ensures the drying method aligns with operational goals and product quality standards.

Rack Drying vs Tunnel Drying Infographic

libmatt.com

libmatt.com