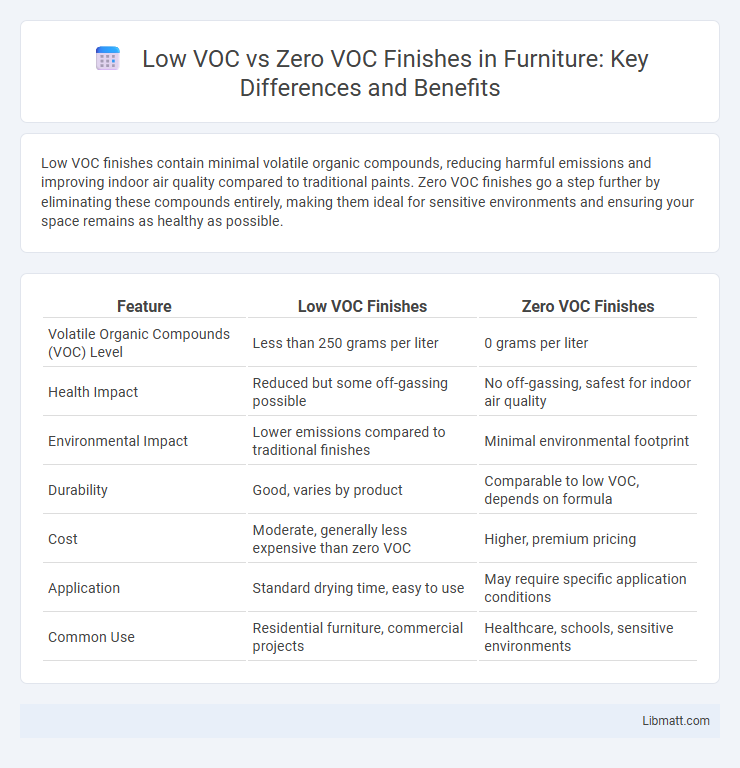

Low VOC finishes contain minimal volatile organic compounds, reducing harmful emissions and improving indoor air quality compared to traditional paints. Zero VOC finishes go a step further by eliminating these compounds entirely, making them ideal for sensitive environments and ensuring your space remains as healthy as possible.

Table of Comparison

| Feature | Low VOC Finishes | Zero VOC Finishes |

|---|---|---|

| Volatile Organic Compounds (VOC) Level | Less than 250 grams per liter | 0 grams per liter |

| Health Impact | Reduced but some off-gassing possible | No off-gassing, safest for indoor air quality |

| Environmental Impact | Lower emissions compared to traditional finishes | Minimal environmental footprint |

| Durability | Good, varies by product | Comparable to low VOC, depends on formula |

| Cost | Moderate, generally less expensive than zero VOC | Higher, premium pricing |

| Application | Standard drying time, easy to use | May require specific application conditions |

| Common Use | Residential furniture, commercial projects | Healthcare, schools, sensitive environments |

Understanding VOCs: What Are They?

VOCs, or volatile organic compounds, are chemicals that easily evaporate at room temperature, contributing to indoor air pollution and potential health risks. Low VOC finishes contain a reduced level of these compounds, minimizing harmful emissions, while zero VOC finishes have little to no detectable VOCs, offering a safer and more environmentally friendly option. Choosing the right finish for your project helps improve indoor air quality and supports a healthier living environment.

Health Impacts of VOC Exposure

Low VOC finishes contain reduced levels of volatile organic compounds compared to traditional paints, which helps decrease indoor air pollution and associated respiratory issues. Zero VOC finishes eliminate these harmful emissions entirely, significantly improving air quality and reducing risks of headaches, allergic reactions, and long-term health problems. Choosing zero VOC products supports healthier living spaces by minimizing your exposure to toxic chemicals.

Low VOC Finishes: Key Characteristics

Low VOC finishes contain reduced levels of volatile organic compounds compared to traditional paints, typically under 250 grams per liter, balancing environmental safety with performance. These finishes often maintain strong durability, color retention, and odor control while minimizing harmful emissions for improved indoor air quality. Low VOC coatings suit applications where moderate environmental benefits are needed without compromising on a broad range of surface protection qualities.

Zero VOC Finishes: What Sets Them Apart?

Zero VOC finishes contain no volatile organic compounds, distinguishing them from low VOC options that still emit minimal levels of these harmful chemicals. These finishes provide superior indoor air quality by eliminating toxic fumes that can cause health issues, making them ideal for sensitive environments like nurseries or healthcare facilities. Choosing zero VOC finishes ensures your space remains safer and more environmentally friendly without compromising on durability or appearance.

Comparing Low VOC vs Zero VOC Finishes

Low VOC finishes contain minimal volatile organic compounds, typically below 250 grams per liter, reducing indoor air pollution while maintaining performance and cost-effectiveness. Zero VOC finishes eliminate volatile organic compounds entirely, offering the highest indoor air quality benefits, ideal for sensitive environments like schools and hospitals. Choosing between low VOC and zero VOC finishes depends on project requirements for environmental impact, regulatory compliance, and budget constraints.

Environmental Benefits of VOC Reduction

Low VOC finishes emit fewer volatile organic compounds compared to traditional paints, significantly reducing indoor air pollution and smog formation. Zero VOC finishes eliminate these compounds almost entirely, providing superior environmental benefits by minimizing harmful emissions that contribute to respiratory problems and environmental degradation. Choosing zero VOC products supports healthier ecosystems and improves indoor air quality, aligning with stricter environmental regulations and sustainable building practices.

Performance and Durability: Low vs Zero VOC

Low VOC finishes often provide enhanced durability and superior performance due to a balanced blend of solvents that improve application and curing, while zero VOC finishes prioritize environmental safety but may compromise on toughness and longevity. Your choice between low and zero VOC finishes should consider that low VOC coatings typically resist wear and chipping better, making them suitable for high-traffic areas. Zero VOC options, although safer for indoor air quality, might require more frequent maintenance or recoating to maintain optimal appearance and protection.

Cost Differences Between Low and Zero VOC Finishes

Zero VOC finishes generally have a higher upfront cost compared to low VOC finishes due to more advanced formulations and stricter environmental standards. Low VOC paints often provide a more budget-friendly option while still reducing harmful emissions, making them popular for cost-sensitive projects. Long-term savings with zero VOC finishes may occur from improved indoor air quality and reduced health-related expenses.

Choosing the Right Finish for Your Project

Choosing the right finish for your project depends on balancing indoor air quality and environmental impact. Low VOC finishes contain small amounts of volatile organic compounds, offering effective performance with reduced odors and health risks compared to traditional paints. Zero VOC finishes eliminate these compounds almost entirely, making them an ideal choice for sensitive spaces where air purity is a priority.

Future Trends in Eco-Friendly Finishes

Future trends in eco-friendly finishes emphasize increased adoption of zero VOC (Volatile Organic Compounds) products due to stringent environmental regulations and growing consumer demand for healthier indoor air quality. Innovations in bio-based and waterborne formulas are driving advancements in zero VOC finishes, offering comparable durability and aesthetic appeal without harmful emissions. The market shift favors zero VOC options as sustainable building certifications and green construction practices prioritize these finishes to minimize environmental impact.

low VOC vs zero VOC finishes Infographic

libmatt.com

libmatt.com