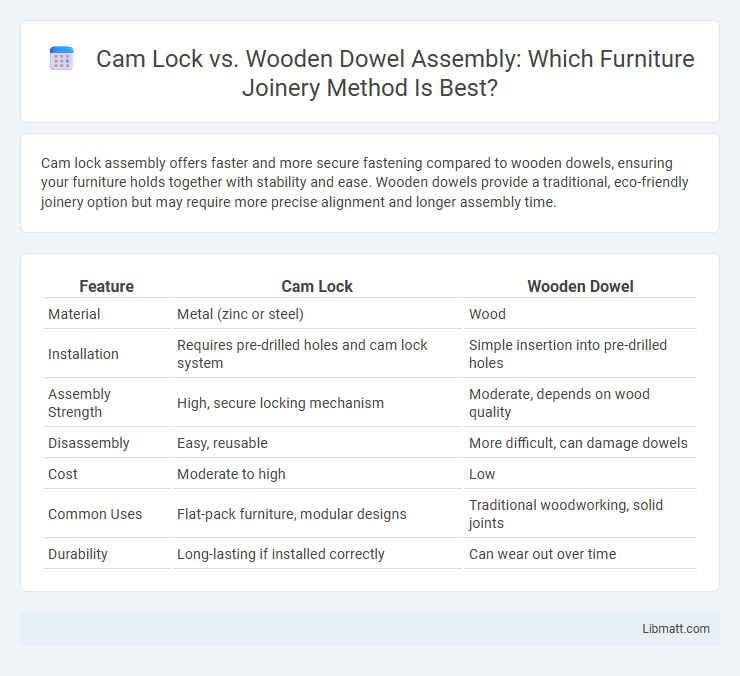

Cam lock assembly offers faster and more secure fastening compared to wooden dowels, ensuring your furniture holds together with stability and ease. Wooden dowels provide a traditional, eco-friendly joinery option but may require more precise alignment and longer assembly time.

Table of Comparison

| Feature | Cam Lock | Wooden Dowel |

|---|---|---|

| Material | Metal (zinc or steel) | Wood |

| Installation | Requires pre-drilled holes and cam lock system | Simple insertion into pre-drilled holes |

| Assembly Strength | High, secure locking mechanism | Moderate, depends on wood quality |

| Disassembly | Easy, reusable | More difficult, can damage dowels |

| Cost | Moderate to high | Low |

| Common Uses | Flat-pack furniture, modular designs | Traditional woodworking, solid joints |

| Durability | Long-lasting if installed correctly | Can wear out over time |

Introduction to Furniture Assembly Methods

Cam lock and wooden dowel assembly are common furniture joining methods that provide sturdy connections for flat-pack or modular pieces. Cam locks use metal fasteners and pre-drilled holes, offering easy installation and strong, hidden joints ideal for ready-to-assemble furniture. Wooden dowels rely on precise alignment and glue to secure parts, ensuring durability and a traditional woodworking appeal for your furniture projects.

What is a Cam Lock Assembly?

A Cam Lock Assembly is a fastening system commonly used in flat-pack furniture for quick and secure joining of panels. It consists of a cam, which is a cylindrical metal piece, and a dowel that fits into the cam, allowing you to tighten and lock components firmly together without tools like screws or nails. This mechanism ensures strong, stable connections and easy disassembly compared to traditional wooden dowel assembly methods.

Understanding Wooden Dowel Assembly

Wooden dowel assembly relies on cylindrical wooden pins inserted into pre-drilled holes to align and join two pieces of wood securely. This method offers natural strength and durability due to the hardwood composition of dowels, providing a seamless and invisible connection without the need for metal hardware. Properly sized and glued dowels ensure precise alignment and resistance to shear forces, making wooden dowel assembly a preferred choice in fine woodworking and furniture construction.

Key Differences Between Cam Lock and Wooden Dowel

Cam locks offer a stronger and more secure connection compared to wooden dowels, using metal fasteners that lock tightly, while wooden dowels rely on friction fit and glue for assembly. Cam locks allow for easier disassembly and reassembly without damaging the material, making them ideal for flat-pack furniture, whereas wooden dowels provide a more permanent joint with less hardware but can be harder to align correctly. Your choice between cam lock and wooden dowel assembly depends on whether you prioritize convenience and strength or a traditional, hardware-free connection.

Strength and Durability Comparison

Cam lock assemblies provide superior strength and durability compared to wooden dowels, thanks to their metal locking mechanism that secures joints tightly and resists loosening over time. Wooden dowels, while offering good alignment and ease of installation, are more prone to wear and weakening under repeated stress or humidity fluctuations. Ensuring your furniture uses cam locks can enhance long-term stability and minimize the risk of joint failure.

Assembly Time and Ease of Installation

Cam lock assemblies typically offer faster assembly times due to their simple locking mechanism that requires minimal tools, making installation straightforward and efficient. Wooden dowel assemblies often demand precise alignment and can be more time-consuming, requiring glue and clamps to secure joints properly. For projects prioritizing ease of installation and reduced labor time, cam locks provide a significant advantage over traditional wooden dowels.

Cost Implications: Cam Lock vs Wooden Dowel

Cam lock assemblies typically involve higher upfront costs due to the complexity of the hardware and installation process compared to wooden dowels. Wooden dowels offer a more economical solution because of their lower material cost and simpler assembly, making them ideal for budget-conscious projects. However, cam locks provide stronger joint stability, potentially reducing long-term maintenance expenses associated with wooden dowel connections.

Common Applications in Modern Furniture

Cam lock and wooden dowel assemblies serve distinct purposes in modern furniture construction, with cam locks favored for flat-pack furniture requiring quick and sturdy assembly, such as bookshelves, cabinets, and office desks. Wooden dowels are commonly used in traditional woodworking, offering strong joints in solid wood furniture like chairs, tables, and bed frames. Your choice depends on the desired balance between ease of assembly and long-term structural integrity.

Pros and Cons of Each Method

Cam lock assemblies offer quick installation and strong, reliable joints ideal for ready-to-assemble furniture, but they require precision machining and small parts that may loosen over time. Wooden dowel assembly provides natural alignment and strong connections without metal hardware, making it cost-effective and eco-friendly, yet it demands precise drilling and can be less durable under repeated disassembly. Both methods balance ease of assembly, strength, and cost, with cam locks favoring convenience and dowels prioritizing traditional craftsmanship.

Choosing the Right Assembly for Your Needs

Selecting the appropriate assembly method depends on factors such as strength requirements, ease of installation, and disassembly frequency. Cam locks offer quick, tool-free assembly with strong, reusable joints ideal for flat-pack furniture and frequent moves. Wooden dowels provide sturdier, permanent connections best suited for heavy-duty applications where long-term rigidity is essential.

Cam Lock vs Wooden Dowel Assembly Infographic

libmatt.com

libmatt.com