The dovetail joint offers exceptional resistance to pulling forces due to its interlocking design, making it ideal for drawer construction and box making. Mortise and tenon joints provide superior strength and stability in framing and furniture, as the tenon fits securely into the mortise, creating a durable connection for your woodworking projects.

Table of Comparison

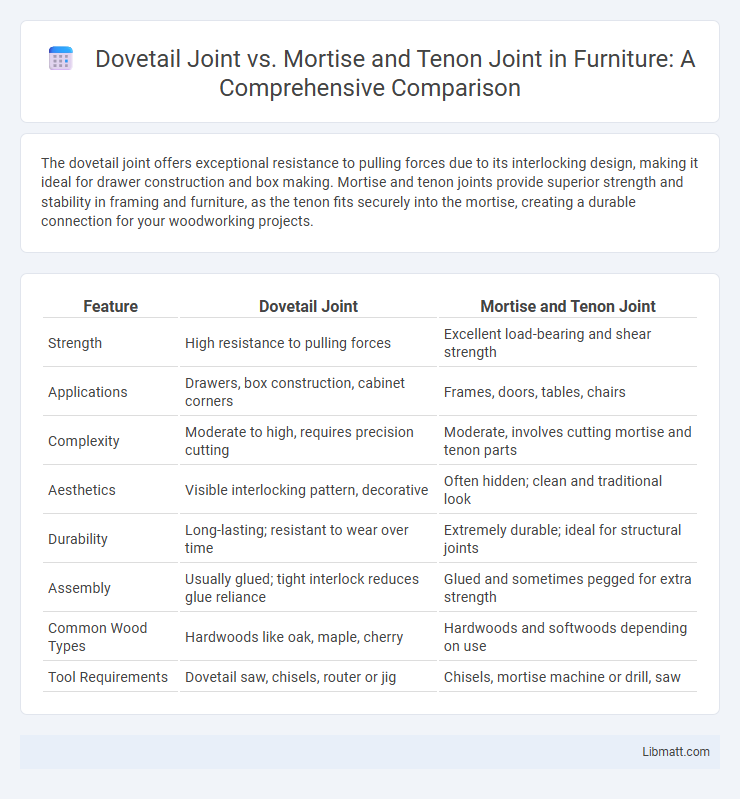

| Feature | Dovetail Joint | Mortise and Tenon Joint |

|---|---|---|

| Strength | High resistance to pulling forces | Excellent load-bearing and shear strength |

| Applications | Drawers, box construction, cabinet corners | Frames, doors, tables, chairs |

| Complexity | Moderate to high, requires precision cutting | Moderate, involves cutting mortise and tenon parts |

| Aesthetics | Visible interlocking pattern, decorative | Often hidden; clean and traditional look |

| Durability | Long-lasting; resistant to wear over time | Extremely durable; ideal for structural joints |

| Assembly | Usually glued; tight interlock reduces glue reliance | Glued and sometimes pegged for extra strength |

| Common Wood Types | Hardwoods like oak, maple, cherry | Hardwoods and softwoods depending on use |

| Tool Requirements | Dovetail saw, chisels, router or jig | Chisels, mortise machine or drill, saw |

Overview of Dovetail and Mortise & Tenon Joints

Dovetail and mortise and tenon joints are fundamental woodworking techniques renowned for their strength and durability in furniture making. The dovetail joint features interlocking trapezoidal pins and tails, providing excellent resistance to pulling forces, making it ideal for drawer construction. Mortise and tenon joints involve a rectangular tenon fitting snugly into a corresponding mortise, offering superior structural stability for frames and heavy load-bearing furniture, ensuring Your projects endure over time.

Historical Background and Traditional Uses

Dovetail joints date back to ancient Egypt and were primarily used in fine woodworking for drawers and boxes due to their exceptional tensile strength. Mortise and tenon joints have an even older history, appearing in Neolithic woodworking and widely employed in timber framing and furniture construction for their durable, load-bearing properties. Both joints remain fundamental in traditional craftsmanship, embodying centuries of structural ingenuity and aesthetic refinement.

Structural Strength Comparison

Dovetail joints offer exceptional resistance to tension and pulling forces due to their interlocking design, making them ideal for drawer construction and box joints. Mortise and tenon joints provide superior compressive strength and stability under load, commonly used in chair and frame assemblies where weight-bearing capacity is crucial. Your choice depends on the specific structural demands, with dovetails excelling in tensile strength and mortise and tenon joints excelling in load-bearing applications.

Aesthetic Appeal and Visual Differences

Dovetail joints feature interlocking trapezoidal pins and tails that create a distinctive, decorative pattern often highlighted in fine woodworking and drawer construction. Mortise and tenon joints, characterized by a rectangular tenon fitting snugly into a matching mortise, offer a more subtle and traditional appearance, frequently concealed within the wood for a clean, minimalist look. The visible complexity of dovetail joints typically enhances aesthetic appeal, while mortise and tenon joints prioritize structural integrity with understated elegance.

Ease of Construction and Required Skill Level

Dovetail joints require precise cutting and fitting, demanding advanced woodworking skills and specialized tools to achieve tight, interlocking tails and pins. Mortise and tenon joints are generally easier to construct with common woodworking tools and can be mastered by intermediate woodworkers through practice. Both joints offer strong structural integrity, but mortise and tenon is often favored for projects requiring faster assembly and less intricate craftsmanship.

Material Suitability and Application

Dovetail joints are ideally suited for hardwoods like oak and maple, offering superior resistance to tension and often used in drawer construction and cabinetry where strength and aesthetic appeal are critical. Mortise and tenon joints excel in both hardwood and softwood applications, commonly employed in structural framing, furniture making, and door construction due to their ability to withstand heavy loads and provide robust, long-lasting connections. The choice between these joints depends on the material characteristics and the specific mechanical demands of the project.

Common Uses in Woodworking Projects

Dovetail joints are commonly used in drawer construction and box-making due to their strong mechanical interlocking and resistance to pulling apart. Mortise and tenon joints are frequently found in furniture framing and door construction, providing robust load-bearing strength and stability. Your choice depends on the project's need for precise alignment and structural integrity, with dovetails excelling in fine joinery and mortise and tenon favored for heavy-duty connections.

Durability and Long-term Performance

Dovetail joints offer exceptional durability and resistance to pulling forces due to their interlocking design, making them ideal for drawer construction where long-term performance is critical. Mortise and tenon joints provide superior strength in framework applications, effectively bearing heavy loads and stress over time by creating a strong, tight-fitting connection. Your choice between these joints should consider the specific structural demands and longevity requirements of your woodworking project.

Cost and Tool Requirements

Dovetail joints generally require more specialized tools such as dovetail saws and chisels, which can increase initial costs and demand higher skill levels, making them more time-consuming and potentially expensive for beginners. Mortise and tenon joints typically need fewer specialized tools--like a mortise chisel and saw--and can be more cost-effective for both materials and execution, especially in mass production or furniture-making settings. Your choice between these joints may depend on budget constraints and available tools, with mortise and tenon joints offering a balance of strength and lower tool investment.

Choosing the Right Joint for Your Project

Choosing the right joint for your project depends on the desired strength, aesthetics, and application. Dovetail joints offer superior tensile strength and are ideal for drawer construction due to their interlocking pins and tails. Mortise and tenon joints provide excellent load-bearing capacity and are preferred for framing and furniture assembling where structural integrity is critical.

dovetail joint vs mortise and tenon joint Infographic

libmatt.com

libmatt.com