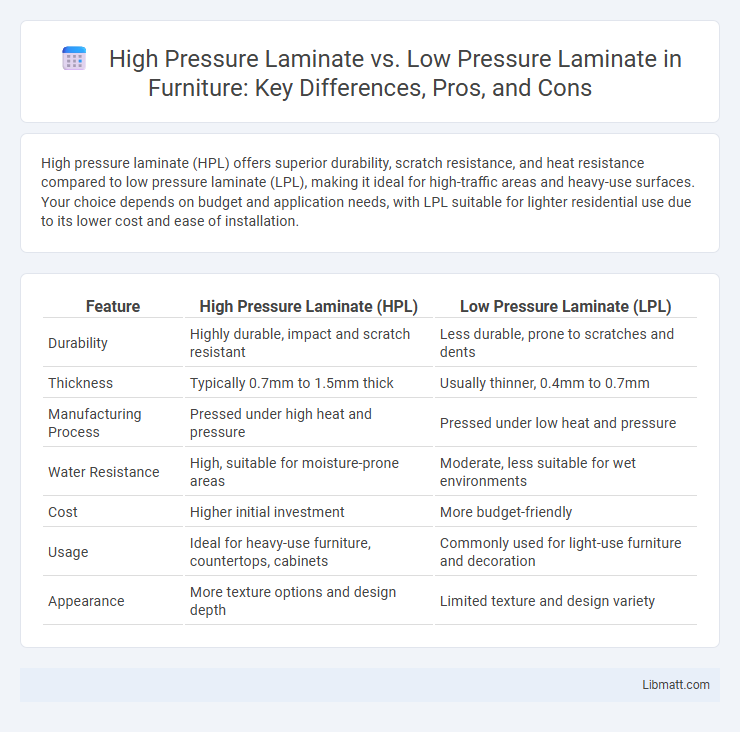

High pressure laminate (HPL) offers superior durability, scratch resistance, and heat resistance compared to low pressure laminate (LPL), making it ideal for high-traffic areas and heavy-use surfaces. Your choice depends on budget and application needs, with LPL suitable for lighter residential use due to its lower cost and ease of installation.

Table of Comparison

| Feature | High Pressure Laminate (HPL) | Low Pressure Laminate (LPL) |

|---|---|---|

| Durability | Highly durable, impact and scratch resistant | Less durable, prone to scratches and dents |

| Thickness | Typically 0.7mm to 1.5mm thick | Usually thinner, 0.4mm to 0.7mm |

| Manufacturing Process | Pressed under high heat and pressure | Pressed under low heat and pressure |

| Water Resistance | High, suitable for moisture-prone areas | Moderate, less suitable for wet environments |

| Cost | Higher initial investment | More budget-friendly |

| Usage | Ideal for heavy-use furniture, countertops, cabinets | Commonly used for light-use furniture and decoration |

| Appearance | More texture options and design depth | Limited texture and design variety |

Introduction to High Pressure Laminate (HPL) and Low Pressure Laminate (LPL)

High Pressure Laminate (HPL) is a durable surface material manufactured by bonding multiple layers of kraft paper impregnated with resin under high heat and pressure, resulting in a tough, water-resistant finish commonly used in countertops and furniture. Low Pressure Laminate (LPL), also known as melamine, is made by fusing decorative paper to particleboard or MDF with lower heat and pressure, offering a cost-effective option with less impact resistance and durability compared to HPL. Understanding the differences in production and performance helps you select the right laminate type for your specific home or commercial application.

Manufacturing Process: HPL vs LPL

High Pressure Laminate (HPL) is produced by applying high heat (typically around 120-150degC) and pressure (usually 1000-1500 psi) to resin-impregnated layers of kraft paper and decorative sheets, resulting in a dense, durable surface. Low Pressure Laminate (LPL), also known as melamine, is manufactured by fusing resin-coated decorative paper onto a substrate like particleboard using lower heat and pressure, typically in a single-stage pressing process. Your choice between HPL and LPL depends on the required durability, with HPL offering superior strength due to its intensive manufacturing process.

Material Composition Differences

High pressure laminate (HPL) consists of multiple layers of kraft paper impregnated with phenolic resin, topped with a decorative paper layer saturated with melamine resin, all bonded together under high heat (around 120-150degC) and pressure (up to 1,400 psi), resulting in a dense, durable surface. Low pressure laminate (LPL) uses a similar decorative paper soaked in melamine resin but is fused onto substrate material like particleboard or MDF using lower heat and pressure, usually below 100degC and 300 psi, leading to a thinner, less robust finish. The key difference in material composition lies in HPL's compacted layers and resin saturation, which provides superior resistance to impact, heat, and moisture compared to the thinner, less resin-saturated LPL.

Durability and Strength Comparison

High pressure laminate (HPL) offers superior durability and strength due to its dense composition and heat-pressed layers, making it highly resistant to impact, scratches, and wear. Low pressure laminate (LPL) features a thinner, less compressed structure, resulting in lower resistance to damage and reduced longevity under heavy use. HPL is preferred for high-traffic and demanding environments, while LPL suits lighter applications with minimal stress.

Aesthetic Options and Design Flexibility

High Pressure Laminate (HPL) offers superior aesthetic options and design flexibility with its wide range of vibrant colors, textures, and patterns that mimic natural materials such as wood and stone more convincingly than Low Pressure Laminate (LPL). HPL's durability allows for more complex shapes and applications, including curved surfaces and high-traffic areas, without compromising visual appeal. LPL, while more limited in design variety and prone to wear, remains a cost-effective choice for basic interior applications with less demanding aesthetic requirements.

Cost Analysis: HPL vs LPL

High Pressure Laminate (HPL) typically costs more upfront due to its dense, durable construction and superior resistance to wear, making it ideal for high-traffic areas. Low Pressure Laminate (LPL) offers a more budget-friendly option but may compromise on longevity and scratch resistance, affecting long-term value. Your choice depends on balancing initial expenditure with durability needs, where HPL often provides better cost efficiency over time despite higher initial investment.

Ideal Applications for High Pressure Laminate

High Pressure Laminate (HPL) is ideal for high-traffic environments such as commercial countertops, office furniture, and wall panels due to its superior durability and resistance to scratches, heat, and impact. It is commonly used in healthcare facilities and educational institutions where hygiene and longevity are critical. Compared to Low Pressure Laminate (LPL), HPL offers enhanced structural integrity, making it suitable for heavy-use surfaces requiring long-lasting performance.

Best Use Cases for Low Pressure Laminate

Low Pressure Laminate (LPL) is best suited for applications requiring cost-effective, lightweight, and moderately durable surfaces, such as office furniture, cabinetry, and wall paneling. Its resistance to scratches, moisture, and heat makes it ideal for environments with moderate wear and tear, including residential kitchens and commercial interiors. LPL is preferred over High Pressure Laminate (HPL) when budget constraints and ease of installation are primary considerations without compromising on basic durability.

Maintenance and Longevity Considerations

High pressure laminate (HPL) offers superior durability and resistance to scratches, heat, and impact, resulting in lower maintenance requirements and a longer lifespan compared to low pressure laminate (LPL). LPL is more prone to wear and damage from moisture and abrasion, necessitating more frequent repairs or replacement in high-traffic or demanding environments. Choosing HPL enhances overall longevity and reduces long-term maintenance costs, making it ideal for commercial settings and heavy-use applications.

Conclusion: Choosing Between HPL and LPL

High Pressure Laminate (HPL) offers superior durability, resistance to impact, heat, and scratches, making it ideal for high-traffic areas and heavy-use surfaces, while Low Pressure Laminate (LPL) provides a cost-effective, lighter option suitable for low-traffic applications. Your choice should depend on the required durability, budget, and intended use, with HPL favored for commercial or demanding environments and LPL fitting more affordable or decorative needs. Evaluating surface performance, longevity, and installation requirements ensures the optimal laminate selection for your specific project.

high pressure laminate vs low pressure laminate Infographic

libmatt.com

libmatt.com