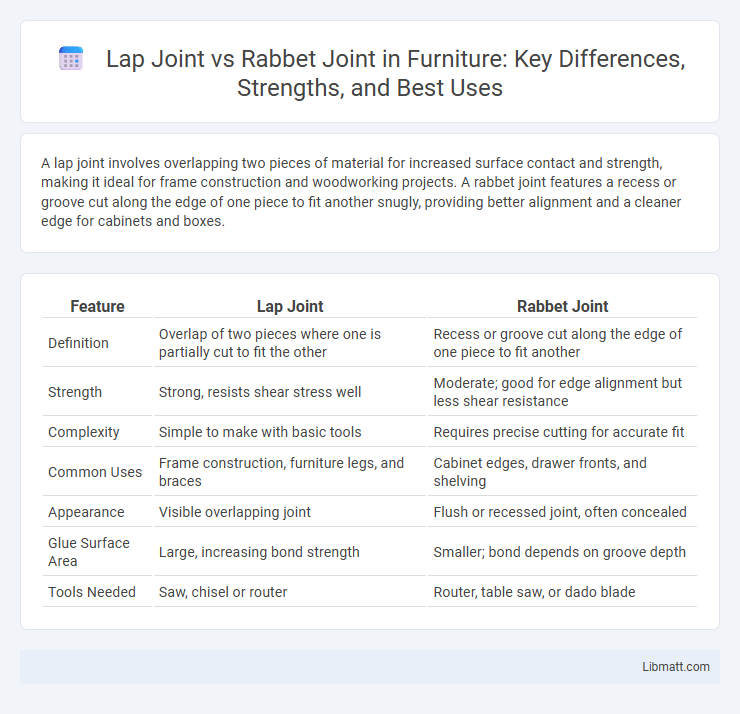

A lap joint involves overlapping two pieces of material for increased surface contact and strength, making it ideal for frame construction and woodworking projects. A rabbet joint features a recess or groove cut along the edge of one piece to fit another snugly, providing better alignment and a cleaner edge for cabinets and boxes.

Table of Comparison

| Feature | Lap Joint | Rabbet Joint |

|---|---|---|

| Definition | Overlap of two pieces where one is partially cut to fit the other | Recess or groove cut along the edge of one piece to fit another |

| Strength | Strong, resists shear stress well | Moderate; good for edge alignment but less shear resistance |

| Complexity | Simple to make with basic tools | Requires precise cutting for accurate fit |

| Common Uses | Frame construction, furniture legs, and braces | Cabinet edges, drawer fronts, and shelving |

| Appearance | Visible overlapping joint | Flush or recessed joint, often concealed |

| Glue Surface Area | Large, increasing bond strength | Smaller; bond depends on groove depth |

| Tools Needed | Saw, chisel or router | Router, table saw, or dado blade |

Introduction to Lap Joint and Rabbet Joint

Lap joints create strong, overlapping connections commonly used in woodworking and metalworking for frames and boxes. Rabbet joints, featuring a recess cut along the edge of one piece, provide flush surfaces often applied in cabinetmaking and drawer construction. Understanding the structural differences between lap and rabbet joints ensures Your projects achieve optimal strength and aesthetic appeal.

Definition of Lap Joint

A lap joint is a woodworking or metalworking joint where two materials overlap each other, creating a strong, flush connection by fastening through welding, adhesives, or mechanical fasteners. Unlike a rabbet joint, which involves a recess or groove cut along the edge of one piece to accept another, the lap joint relies on the overlapping surface area to provide strength and stability. Your choice between a lap joint and a rabbet joint depends on the specific structural requirements and aesthetic preferences of your project.

Definition of Rabbet Joint

A rabbet joint is a woodworking technique where an edge or end of a board is cut to form a recess or groove, allowing another piece to fit snugly into it for a strong corner connection. Unlike a lap joint, which involves overlapping two pieces of wood of equal thickness, the rabbet joint creates a stepped edge, enhancing alignment and strength in frames or cabinet construction. You can achieve cleaner edges and improved stability in your projects by choosing a rabbet joint for joining boards at right angles.

Key Structural Differences

Lap joints feature two overlapping pieces of wood joined by adhesive or fasteners, providing increased surface area for stronger bonding and resistance to shear forces. Rabbet joints involve one piece with a recessed edge fitting into a corresponding groove on the other piece, offering greater alignment precision but less surface area for bonding compared to lap joints. The lap joint's overlapping design excels in load distribution, while the rabbet joint is often preferred for edge-to-edge assembly requiring neat corner alignment.

Strength and Durability Comparison

Lap joints offer superior strength and durability due to the increased gluing surface area and mechanical interlocking, making them ideal for load-bearing applications. Rabbet joints provide moderate strength, primarily relying on adhesive bonding and fasteners, which may result in reduced durability under stress or heavy loads. Choosing between lap and rabbet joints depends on the structural requirements and desired longevity of the woodworking or construction project.

Common Applications

Lap joints are commonly used in woodworking and metalworking for frames, cabinets, and furniture due to their strength and ease of assembly. Rabbet joints are often applied in cabinetry, drawer construction, and box making where edge alignment and surface area for gluing are critical. Both joints provide stability, but lap joints are preferred for load-bearing structures while rabbet joints excel in creating flush and precise edges.

Material Compatibility

Lap joints offer great material compatibility, working well with wood, metal, and plastic due to their overlapping design that distributes stress evenly. Rabbet joints are primarily suited for woodworking, especially in cabinet and drawer construction, where the recessed edge provides a strong, precise fit. The choice between lap and rabbet joints depends on the specific materials involved and the required joint strength for the application.

Ease of Construction

Lap joints offer easier construction due to their simple overlapping design, requiring minimal tools and precise cuts, making them ideal for quick and sturdy assemblies. Rabbet joints involve cutting a notch or recess along the edge, which demands more accurate measurements and specialized tools but provides a neat, flush finish. Your choice depends on balancing ease of construction with the desired joint appearance and strength.

Cost and Resource Implications

Lap joints typically require less material and simpler tools, making them more cost-effective for basic woodworking projects. Rabbet joints often demand precise cutting and additional labor, increasing both time and resource investment. Manufacturers choosing between these joints must balance material savings against the complexity and skill required during assembly.

Choosing the Right Joint for Your Project

Selecting the appropriate joint between a lap joint and a rabbet joint depends on the required strength and aesthetic finish of the project. Lap joints offer superior load-bearing capacity and are ideal for structural applications like framing, while rabbet joints provide a cleaner edge suitable for cabinetry and decorative boxes. Consider factors such as material thickness, stress distribution, and visible seams to ensure durability and desired appearance in your woodworking project.

lap joint vs rabbet joint Infographic

libmatt.com

libmatt.com