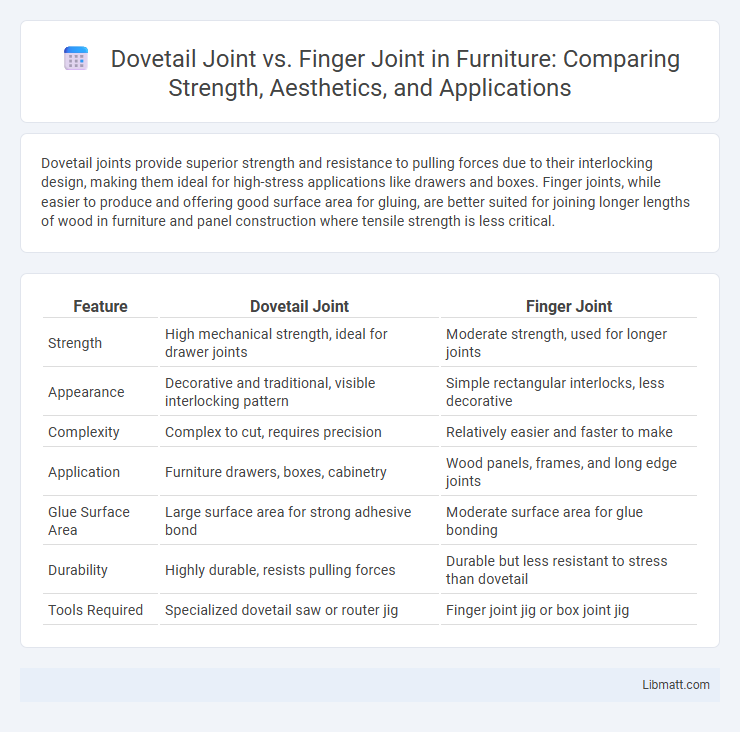

Dovetail joints provide superior strength and resistance to pulling forces due to their interlocking design, making them ideal for high-stress applications like drawers and boxes. Finger joints, while easier to produce and offering good surface area for gluing, are better suited for joining longer lengths of wood in furniture and panel construction where tensile strength is less critical.

Table of Comparison

| Feature | Dovetail Joint | Finger Joint |

|---|---|---|

| Strength | High mechanical strength, ideal for drawer joints | Moderate strength, used for longer joints |

| Appearance | Decorative and traditional, visible interlocking pattern | Simple rectangular interlocks, less decorative |

| Complexity | Complex to cut, requires precision | Relatively easier and faster to make |

| Application | Furniture drawers, boxes, cabinetry | Wood panels, frames, and long edge joints |

| Glue Surface Area | Large surface area for strong adhesive bond | Moderate surface area for glue bonding |

| Durability | Highly durable, resists pulling forces | Durable but less resistant to stress than dovetail |

| Tools Required | Specialized dovetail saw or router jig | Finger joint jig or box joint jig |

Introduction to Wood Joinery

Dovetail joints and finger joints are fundamental techniques in wood joinery, each offering distinct strengths for crafting durable furniture and cabinetry. Dovetail joints feature interlocking wedge-shaped pins and tails that provide exceptional tensile strength and resistance to being pulled apart, making them ideal for drawer construction and fine woodworking. Finger joints consist of rectangular interlocking fingers that maximize gluing surface area, often used for lengthening wood pieces or creating box joints, balancing strength and ease of assembly for your woodworking projects.

What is a Dovetail Joint?

A dovetail joint is a woodworking technique characterized by interlocking trapezoidal-shaped pins and tails, creating a strong mechanical bond commonly used in cabinetry and drawer construction. This joint offers superior resistance to being pulled apart compared to finger joints, due to its angled design that locks components securely. The precision required for cutting dovetails enhances the aesthetic appeal, making it both functional and decorative in fine woodworking projects.

What is a Finger Joint?

A finger joint, also known as a box joint, consists of interlocking rectangular pins that fit together to form a strong, straight-grain connection ideal for box construction and panel edges. Unlike a dovetail joint, which uses trapezoidal tails for added tensile strength and resistance to pulling apart, the finger joint offers ease of fabrication and increased gluing surface area. Your woodworking projects benefit from the finger joint's precise alignment and mechanical strength, making it a preferred choice for simple, durable corner joints.

Key Differences Between Dovetail and Finger Joints

Dovetail joints feature interlocking trapezoidal pins and tails that provide superior tensile strength and resistance to pulling apart, making them ideal for drawer construction and high-stress applications. Finger joints, also known as box joints, consist of rectangular interlocking fingers that offer easier manufacturing and greater surface area for gluing, enhancing overall bond strength mainly in box and frame assemblies. The key differences lie in the joint shape, mechanical strength, and complexity of cutting, with dovetails being more decorative and robust, while finger joints prioritize simplicity and gluing surface area.

Strength and Durability Comparison

Dovetail joints offer superior strength and durability due to their interlocking trapezoidal pins and tails, which provide excellent resistance to pulling forces and mechanical stress, making them ideal for heavy-duty woodworking projects like drawers and cabinetry. Finger joints, while also strong and durable, rely on multiple rectangular pins and grooves glued together, which can be susceptible to shear stress and may require precise adhesive application to maximize stability. Overall, dovetail joints generally outperform finger joints in long-term durability and mechanical strength, particularly in applications demanding high tensile resistance.

Visual Appeal and Aesthetics

Dovetail joints offer a distinct visual appeal with their interlocking, trapezoidal shapes that emphasize craftsmanship and strength, often enhancing the aesthetic value of fine woodworking projects. Finger joints present a more uniform, rectangular pattern that provides a clean, modern look suitable for contemporary designs and large surface areas. Your choice depends on whether you prefer the traditional, decorative elegance of dovetails or the sleek, repetitive appearance of finger joints.

Applications and Best Use Cases

Dovetail joints are ideal for high-strength applications in drawer construction and fine woodworking, offering superior resistance to pulling forces due to their interlocking trapezoidal shapes. Finger joints excel in manufacturing longer wood pieces from shorter lengths, commonly used in door panels, molding, and furniture components, providing enhanced surface area for strong glue bonds. Both joints improve structural integrity, but dovetails are preferred for visible, decorative joints while finger joints suit mass production and material optimization.

Tools and Skill Level Required

Dovetail joints require precision hand tools like dovetail saws, chisels, and marking gauges, demanding advanced woodworking skills for accurate angled cuts and tight-fitting interlocking tails and pins. Finger joints utilize simpler tools such as table saws or router tables with straight bits, making them more accessible for intermediate woodworkers seeking strong, straight-cut joints. While both require careful measurement, dovetail joints typically involve greater craftsmanship and experience compared to the relatively straightforward finger joint technique.

Cost and Efficiency Factors

Dovetail joints typically require more time and precision, resulting in higher labor costs compared to finger joints, which are easier to machine and assemble, making them more cost-effective for mass production. Finger joints offer increased efficiency in manufacturing due to their compatibility with automated cutting tools, reducing overall production time and labor expenses. Choosing between the two depends on your project's budget and desired balance between traditional craftsmanship and cost-efficient assembly.

Choosing the Right Joint for Your Project

Dovetail joints offer superior strength and an aesthetically pleasing interlocking pattern, making them ideal for high-quality furniture and drawer construction. Finger joints provide a simpler, more efficient way to join wood at right angles with increased gluing surface area, suitable for box frameworks and mass production. Your choice depends on the balance between visual appeal, structural integrity, and the specific demands of your woodworking project.

Dovetail joint vs finger joint Infographic

libmatt.com

libmatt.com