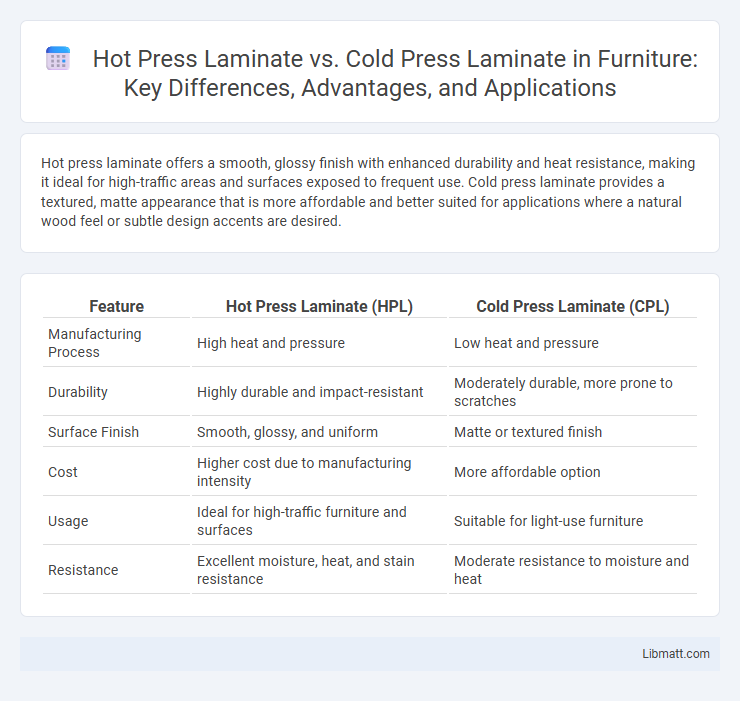

Hot press laminate offers a smooth, glossy finish with enhanced durability and heat resistance, making it ideal for high-traffic areas and surfaces exposed to frequent use. Cold press laminate provides a textured, matte appearance that is more affordable and better suited for applications where a natural wood feel or subtle design accents are desired.

Table of Comparison

| Feature | Hot Press Laminate (HPL) | Cold Press Laminate (CPL) |

|---|---|---|

| Manufacturing Process | High heat and pressure | Low heat and pressure |

| Durability | Highly durable and impact-resistant | Moderately durable, more prone to scratches |

| Surface Finish | Smooth, glossy, and uniform | Matte or textured finish |

| Cost | Higher cost due to manufacturing intensity | More affordable option |

| Usage | Ideal for high-traffic furniture and surfaces | Suitable for light-use furniture |

| Resistance | Excellent moisture, heat, and stain resistance | Moderate resistance to moisture and heat |

Introduction to Laminate Pressing Techniques

Hot press laminate uses heat and pressure to bond materials, enhancing durability and creating a smooth, glossy finish ideal for high-traffic surfaces. Cold press laminate relies on pressure without heat, preserving the texture and pattern integrity while offering a cost-effective and environmentally friendly option. Both techniques are essential in furniture manufacturing, with selection dependent on desired surface quality and application requirements.

What is Hot Press Laminate?

Hot Press Laminate (HPL) is a durable composite material created by bonding multiple layers of kraft paper or cellulose fiber with resin under high heat and pressure, resulting in a hard, dense surface resistant to scratches and impacts. Commonly used for countertops, furniture, and cabinetry, HPL provides excellent moisture resistance and heat tolerance compared to other laminates. The manufacturing process involves pressing the resin-impregnated layers between heated plates, which enhances the laminate's strength and adhesion properties.

What is Cold Press Laminate?

Cold Press Laminate is a type of decorative surface material created by bonding layers of paper or fabric with resin under low temperature and pressure, resulting in a smoother, less dense finish compared to Hot Press Laminate. This method preserves the texture of the underlying substrate, making it ideal for applications requiring a matte or natural look, such as furniture panels and wall coverings. Cold Press Laminate offers enhanced resistance to scratches and wear while maintaining a cost-effective production process suitable for large-scale manufacturing.

Key Differences Between Hot Press and Cold Press Laminate

Hot Press Laminate involves applying heat and pressure to bond layers, resulting in a smoother, more durable surface ideal for high-traffic areas. Cold Press Laminate uses pressure without heat, producing a less dense, more flexible finish suited for decorative applications and lighter use. The temperature difference during bonding significantly affects the laminate's strength, texture, and resistance to wear and moisture.

Advantages of Hot Press Laminating

Hot press laminating offers superior surface durability due to the high heat and pressure applied, resulting in a smoother, more resilient finish ideal for high-traffic materials. This method enhances adhesive bonding, reducing the risk of delamination and improving moisture resistance compared to cold press laminates. It also delivers better clarity and color vibrancy, making it the preferred choice for premium print protection and long-lasting graphic preservation.

Advantages of Cold Press Laminating

Cold press laminating offers advantages such as reduced heat exposure, preserving the integrity of heat-sensitive materials like photographs, artwork, and certain types of paper. The process ensures a smooth finish with minimal risk of bubbling or warping, resulting in high-quality, durable lamination. Cold press laminates are also ideal for items requiring strong adhesion without heat, making them suitable for delicate or synthetic substrates.

Common Applications: Hot vs Cold Press Laminate

Hot press laminate is commonly used in high-traffic surfaces like countertops, flooring, and cabinetry due to its durability and smooth finish. Cold press laminate is ideal for decorative applications such as wall panels, furniture veneer, and art projects where a more textured surface and cost-effectiveness are important. Your choice depends on whether you prioritize strength and heat resistance or texture and budget for your specific project.

Durability and Performance Comparison

Hot press laminate offers superior durability with a denser, more uniform finish that resists scratches, heat, and moisture better than cold press laminate. Cold press laminate, while more budget-friendly, tends to have a softer finish that may wear faster under heavy use or exposure to harsh conditions. For your projects requiring long-lasting, high-performance surfaces, hot press laminate provides enhanced strength and resilience.

Cost Considerations for Both Methods

Hot press laminate typically incurs higher costs due to its faster production time and superior surface finish, making it ideal for high-quality applications. Cold press laminate is generally more affordable but may require longer curing periods and can result in a less durable surface. Your choice should balance budget constraints with the desired finish quality and production speed.

Choosing the Right Laminate Pressing Method

Hot Press Laminate applies high heat and pressure, resulting in a smoother and more durable surface ideal for high-traffic areas and detailed designs. Cold Press Laminate uses minimal heat, preserving texture and preventing warping, making it suitable for delicate materials and cost-sensitive projects. Selecting the right method depends on the desired finish, material compatibility, and application durability requirements.

Hot Press Laminate vs Cold Press Laminate Infographic

libmatt.com

libmatt.com