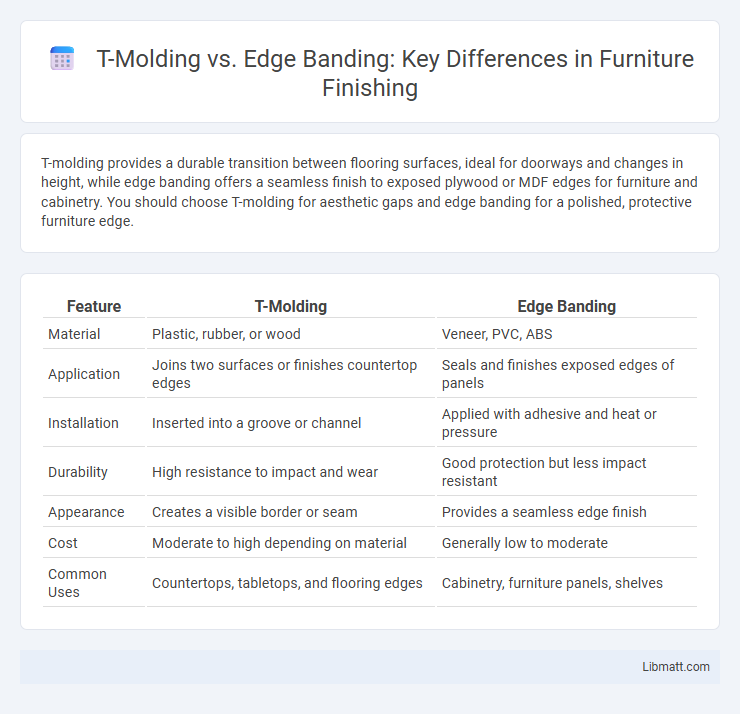

T-molding provides a durable transition between flooring surfaces, ideal for doorways and changes in height, while edge banding offers a seamless finish to exposed plywood or MDF edges for furniture and cabinetry. You should choose T-molding for aesthetic gaps and edge banding for a polished, protective furniture edge.

Table of Comparison

| Feature | T-Molding | Edge Banding |

|---|---|---|

| Material | Plastic, rubber, or wood | Veneer, PVC, ABS |

| Application | Joins two surfaces or finishes countertop edges | Seals and finishes exposed edges of panels |

| Installation | Inserted into a groove or channel | Applied with adhesive and heat or pressure |

| Durability | High resistance to impact and wear | Good protection but less impact resistant |

| Appearance | Creates a visible border or seam | Provides a seamless edge finish |

| Cost | Moderate to high depending on material | Generally low to moderate |

| Common Uses | Countertops, tabletops, and flooring edges | Cabinetry, furniture panels, shelves |

Introduction to T-Molding and Edge Banding

T-molding is a flexible trim used to bridge the gap between two different flooring surfaces, providing a smooth transition and preventing tripping hazards. Edge banding is a thin strip of material, often made from wood veneer or PVC, applied to the exposed edges of plywood or MDF panels to cover raw edges and enhance durability. Both techniques improve the aesthetics and functionality of flooring and cabinetry by protecting vulnerable edges and creating a polished finish.

What is T-Molding?

T-molding is a durable finishing strip used to cover and protect the exposed edges of flooring or countertops, typically made from plastic, wood, or metal. It fits into a T-shaped gap between two surfaces, providing a smooth transition and preventing damage from wear or moisture. Preferred in high-traffic areas, T-molding offers both aesthetic appeal and functional edge protection compared to edge banding.

What is Edge Banding?

Edge banding is a thin strip of material, typically made from wood veneer, PVC, or ABS, applied to the exposed edges of plywood, particleboard, or MDF to create a finished, durable look. It protects furniture and cabinetry from moisture, damage, and wear while enhancing aesthetic appeal by seamlessly covering raw edges. Common edge banding applications include kitchen cabinets, countertops, and office furniture, providing both functional and decorative benefits.

Key Differences Between T-Molding and Edge Banding

T-molding and edge banding differ primarily in application and appearance; T-molding is a T-shaped strip used to create seamless transitions between floorings or countertop edges, while edge banding is a thin veneer or laminate applied to cover the exposed edges of plywood or particleboard. T-molding offers a more durable and flexible finish ideal for flooring joints, whereas edge banding provides a smooth, polished look to furniture edges, enhancing aesthetic appeal. Choosing between these methods depends on your project's functional needs and design preferences.

Material Options for T-Molding and Edge Banding

T-molding is commonly made from durable materials such as PVC, rubber, and aluminum, designed to provide a flexible yet sturdy edge suitable for curved or irregular shapes. Edge banding materials include thermoplastic, wood veneer, melamine, and PVC, each offering a different aesthetic and level of heat and wear resistance tailored for flat board edges. Both options offer diverse material selections to match specific durability needs and design preferences in cabinetry and furniture finishing.

Installation Process: T-Molding vs Edge Banding

T-molding installation involves fitting a pre-formed T-shaped strip into a groove cut along the edge of countertops or flooring, providing a visible seam that accommodates expansion and contraction. Edge banding entails applying a thin strip of veneer, PVC, or wood along exposed panel edges using heat, adhesive, or pressure, creating a seamless, finished appearance. The T-molding process requires precise groove cutting and snap-in placement, while edge banding demands specialized machinery or iron-on techniques for effective adhesion and trimming.

Durability and Maintenance Comparison

T-molding offers superior durability with a robust profile that resists chipping and wear, making it ideal for high-traffic areas. Edge banding, while providing a sleek finish, tends to be less durable due to its thinner application and potential for peeling or damage over time. Maintenance for T-molding is minimal, requiring only occasional cleaning, whereas edge banding may need regular touch-ups or replacements to maintain its appearance and integrity.

Aesthetics and Design Versatility

T-molding provides a sleek, uniform finish that enhances the visual appeal of tabletops with its seamless transition between surfaces, making it ideal for modern and contemporary designs. Edge banding offers greater design versatility by allowing a wide range of colors, textures, and materials to be applied, enabling customization to match various styles from traditional to minimalist. The choice between T-molding and edge banding significantly influences the final aesthetic, with T-molding favoring a clean, defined edge and edge banding supporting more diverse and intricate design possibilities.

Cost Factors: T-Molding vs Edge Banding

T-molding typically incurs higher initial costs due to specialized materials and installation labor, while edge banding offers a more cost-effective solution with lower material and application expenses. Edge banding uses thin strips of laminate or veneer adhered to panel edges, reducing waste and simplifying the process, which minimizes overall project costs. For budget-sensitive projects, edge banding provides a financially efficient choice without compromising edge durability compared to T-molding.

Choosing the Right Solution for Your Project

T-molding offers a durable, flexible option ideal for covering exposed edges in flooring and countertops, providing a clean transition between surfaces. Edge banding is perfect for a seamless, cost-effective finish on plywood or MDF, enhancing both appearance and moisture resistance. Selecting the right solution depends on material type, aesthetic preference, and project durability requirements.

T-molding vs edge banding Infographic

libmatt.com

libmatt.com