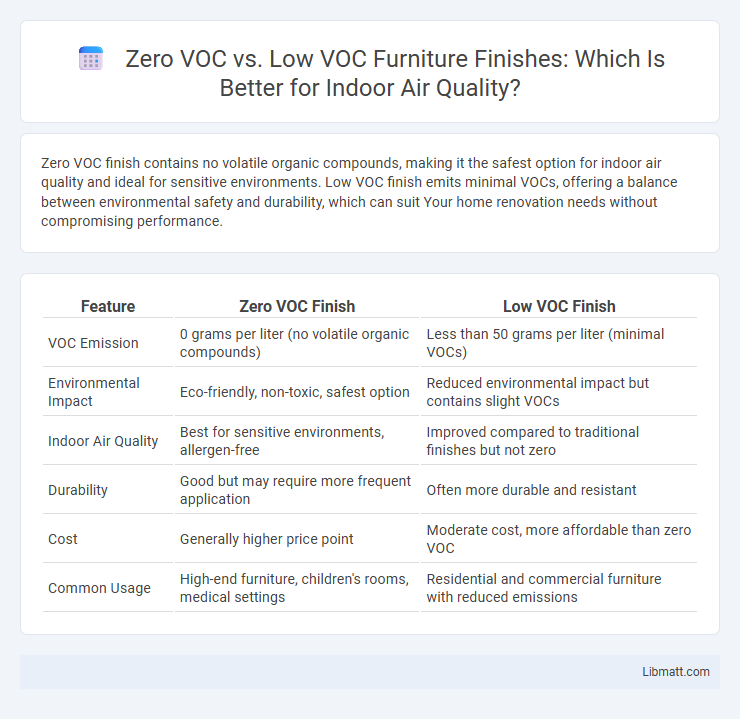

Zero VOC finish contains no volatile organic compounds, making it the safest option for indoor air quality and ideal for sensitive environments. Low VOC finish emits minimal VOCs, offering a balance between environmental safety and durability, which can suit Your home renovation needs without compromising performance.

Table of Comparison

| Feature | Zero VOC Finish | Low VOC Finish |

|---|---|---|

| VOC Emission | 0 grams per liter (no volatile organic compounds) | Less than 50 grams per liter (minimal VOCs) |

| Environmental Impact | Eco-friendly, non-toxic, safest option | Reduced environmental impact but contains slight VOCs |

| Indoor Air Quality | Best for sensitive environments, allergen-free | Improved compared to traditional finishes but not zero |

| Durability | Good but may require more frequent application | Often more durable and resistant |

| Cost | Generally higher price point | Moderate cost, more affordable than zero VOC |

| Common Usage | High-end furniture, children's rooms, medical settings | Residential and commercial furniture with reduced emissions |

Understanding VOCs: What Are They?

Volatile Organic Compounds (VOCs) are chemicals emitted from finishes that contribute to air pollution and can impact indoor air quality by causing health issues like headaches and respiratory irritation. Zero VOC finishes contain no measurable levels of these harmful compounds, making them safer for your living environment, while low VOC finishes have reduced but still present VOC content. Choosing between zero and low VOC finishes involves considering the balance between environmental impact, performance, and your health priorities.

Health Impacts of VOC Exposure

Zero VOC finishes emit no volatile organic compounds, significantly reducing indoor air pollution and lowering the risk of respiratory issues, headaches, and allergic reactions. Low VOC finishes contain small amounts of VOCs, which can still contribute to short-term health effects such as eye irritation and long-term exposure risks like asthma or chronic respiratory problems. Choosing a zero VOC finish protects your indoor environment by minimizing harmful emissions and promoting healthier air quality.

Zero VOC Finishes: Definition and Benefits

Zero VOC finishes contain no volatile organic compounds, making them a safer and healthier choice for indoor environments by minimizing harmful emissions. These finishes improve indoor air quality, reduce allergy risks, and are environmentally friendly, supporting sustainable living. Choosing zero VOC products protects your family and enhances air purity without compromising on durability or aesthetic appeal.

Low VOC Finishes: Definition and Advantages

Low VOC finishes contain a limited amount of volatile organic compounds, typically below 50 grams per liter, making them safer for indoor air quality and reducing environmental impact. These finishes offer a balance between performance and health benefits by minimizing harmful emissions while providing durable protection for surfaces. Your choice of low VOC finishes supports healthier living spaces without sacrificing aesthetic appeal or long-term durability.

Key Differences: Zero VOC vs Low VOC Finishes

Zero VOC finishes contain no volatile organic compounds, ensuring the highest level of indoor air quality and reducing health risks associated with chemical emissions. Low VOC finishes have minimal volatile organic compounds, typically below 50 grams per liter, balancing environmental impact with performance. Both types improve sustainability, but zero VOC is the optimal choice for sensitive environments and eco-friendly projects.

Performance and Durability Comparison

Zero VOC finishes provide excellent durability and resistance to wear, making them ideal for high-traffic areas, while ensuring no harmful chemical emissions. Low VOC finishes offer solid performance with slightly elevated VOC levels but may contain additives that improve drying time and surface hardness. Your choice between the two should consider the specific environmental sensitivity and longevity requirements of your project.

Environmental Impact: Which Is Greener?

Zero VOC finishes contain no volatile organic compounds, significantly reducing air pollution and health risks compared to low VOC finishes, which still emit small amounts of VOCs. The absence of VOCs in zero VOC finishes makes them more environmentally friendly, as they minimize ozone formation and indoor air contamination. Choosing zero VOC finishes supports greater sustainability goals by limiting harmful emissions and improving overall air quality.

Application and Drying Times

Zero VOC finishes typically offer longer drying times due to the absence of volatile organic compounds, which slows solvent evaporation and requires careful application for a smooth finish. Low VOC finishes contain small amounts of VOCs that expedite drying, allowing for quicker recoating and reduced project duration. Your choice between the two influences both the time needed for application and the overall finishing process efficiency.

Cost Considerations: Zero VOC vs Low VOC

Zero VOC finishes typically command higher upfront costs due to stricter formulation requirements and premium raw materials, making them more expensive than low VOC alternatives. Low VOC finishes offer a cost-effective balance by significantly reducing emissions while keeping prices closer to conventional finishes. Budget-conscious projects often choose low VOC options to achieve improved indoor air quality without the premium expense of zero VOC products.

Choosing the Best Finish for Your Project

Zero VOC finishes contain no volatile organic compounds, ensuring the highest indoor air quality and environmental safety, ideal for sensitive spaces like nurseries or healthcare facilities. Low VOC finishes offer reduced emissions compared to traditional paints, balancing durability, color options, and eco-friendliness, making them suitable for most residential or commercial projects. When choosing the best finish for your project, consider factors such as air quality needs, durability requirements, and environmental impact to select the optimal VOC level.

Zero VOC finish vs low VOC finish Infographic

libmatt.com

libmatt.com