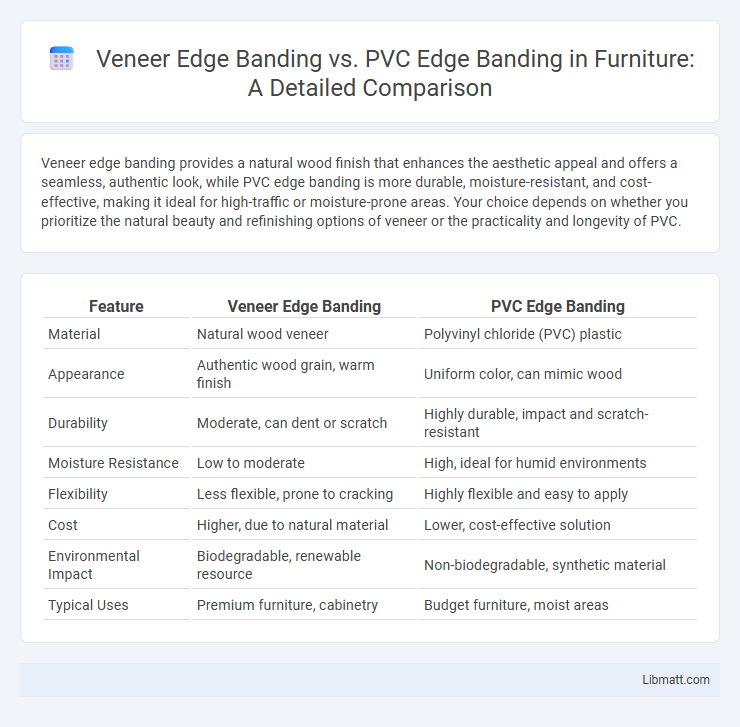

Veneer edge banding provides a natural wood finish that enhances the aesthetic appeal and offers a seamless, authentic look, while PVC edge banding is more durable, moisture-resistant, and cost-effective, making it ideal for high-traffic or moisture-prone areas. Your choice depends on whether you prioritize the natural beauty and refinishing options of veneer or the practicality and longevity of PVC.

Table of Comparison

| Feature | Veneer Edge Banding | PVC Edge Banding |

|---|---|---|

| Material | Natural wood veneer | Polyvinyl chloride (PVC) plastic |

| Appearance | Authentic wood grain, warm finish | Uniform color, can mimic wood |

| Durability | Moderate, can dent or scratch | Highly durable, impact and scratch-resistant |

| Moisture Resistance | Low to moderate | High, ideal for humid environments |

| Flexibility | Less flexible, prone to cracking | Highly flexible and easy to apply |

| Cost | Higher, due to natural material | Lower, cost-effective solution |

| Environmental Impact | Biodegradable, renewable resource | Non-biodegradable, synthetic material |

| Typical Uses | Premium furniture, cabinetry | Budget furniture, moist areas |

Introduction to Edge Banding

Veneer edge banding offers a natural wood finish by applying thin slices of real wood to furniture edges, enhancing aesthetic appeal and texture. PVC edge banding provides a durable, moisture-resistant plastic covering that protects furniture edges from wear and tear while offering a wide range of colors and finishes. Both types improve the structural integrity and visual appeal of furniture but cater to different needs regarding appearance, durability, and cost.

What is Veneer Edge Banding?

Veneer edge banding consists of a thin layer of natural wood applied to the edges of furniture or cabinetry, providing an authentic wood finish that enhances durability and aesthetics. It is typically made from real wood veneers, allowing for a seamless match with hardwood surfaces while offering resistance to chipping and moisture. Your choice of veneer edge banding ensures a high-quality, eco-friendly alternative to synthetic materials like PVC, preserving the natural beauty of wood grain.

What is PVC Edge Banding?

PVC edge banding is a durable plastic material used to cover the exposed edges of plywood, particleboard, or MDF to protect against moisture, impact, and wear. It offers a wide range of colors and finishes, making it ideal for creating seamless, cost-effective furniture edges. Compared to veneer edge banding, PVC provides superior resistance to scratches and heat, ensuring long-lasting edge protection in high-traffic environments.

Aesthetic Differences: Veneer vs PVC

Veneer edge banding offers a natural wood grain appearance that seamlessly matches solid wood surfaces, enhancing the authenticity and warmth of furniture. PVC edge banding provides a consistent, smooth finish available in a wide range of colors and patterns but lacks the organic texture found in veneer. The choice impacts the overall visual appeal, with veneer favored for high-end, natural aesthetics and PVC suited for cost-effective, uniform designs.

Durability and Longevity Comparison

Veneer edge banding offers a natural wood appearance with moderate durability, but it is more susceptible to moisture damage and chipping over time compared to PVC edge banding. PVC edge banding provides superior resistance to impact, moisture, and heat, making it a more durable and long-lasting option for high-traffic or wet environments. Choosing the right edge banding for your project ensures optimal protection and extended lifespan of your surfaces.

Installation Process and Ease of Use

Veneer edge banding requires careful handling during installation, often involving hot-melt glue and precise trimming tools to achieve a seamless, natural wood look, making it more suited for skilled users. PVC edge banding features a straightforward, user-friendly application process using heat activation or adhesive tapes, offering quick and efficient installation with minimal tools. Choosing between the two depends on your need for ease of use versus the authenticity and finish of natural wood veneer.

Environmental Impact and Sustainability

Veneer edge banding, made from thin slices of natural wood, offers a more sustainable option as it is biodegradable and sourced from renewable materials, reducing environmental impact compared to PVC edge banding. PVC edge banding, composed of non-biodegradable plastic derived from fossil fuels, contributes to pollution and landfill waste due to its slow decomposition. Choosing veneer edge banding supports eco-conscious manufacturing and promotes a circular economy by enabling easier recycling or composting.

Cost Analysis: Veneer vs PVC Edge Banding

Veneer edge banding typically incurs higher costs due to the natural wood material and intricate finishing processes, whereas PVC edge banding offers a more budget-friendly solution with lower raw material and manufacturing expenses. The durability of PVC, combined with its ease of installation and availability in various colors, often results in cost savings over time despite veneer's premium appearance. Cost analysis should consider initial investment, maintenance, and potential replacement expenses, where PVC generally outperforms veneer in economic efficiency.

Best Applications for Each Type

Veneer edge banding is best suited for high-end furniture, cabinetry, and decor where natural wood aesthetics are prioritized, offering an authentic wood grain finish and easy refinishing options. PVC edge banding excels in environments requiring durability and moisture resistance, such as kitchens, bathrooms, and commercial settings, providing a cost-effective, maintenance-free alternative available in various colors and textures. Choosing between the two depends on project requirements regarding appearance, budget, and environmental exposure.

Conclusion: Choosing the Right Edge Banding

Veneer edge banding offers a natural wood appearance and can be sanded or stained to match your furniture, making it ideal for high-end cabinetry and hardwood projects. PVC edge banding provides greater durability, moisture resistance, and a wider range of colors and finishes, suited for commercial and moisture-prone environments. Your choice depends on balancing aesthetics, durability, and budget to achieve the desired finish for your woodworking project.

veneer edge banding vs PVC edge banding Infographic

libmatt.com

libmatt.com