Two pack paint offers superior durability and chemical resistance compared to PU paint, making it ideal for industrial applications where long-lasting protection is essential. Your choice depends on the specific requirements, as PU paint provides excellent flexibility and gloss, suitable for automotive and decorative finishes.

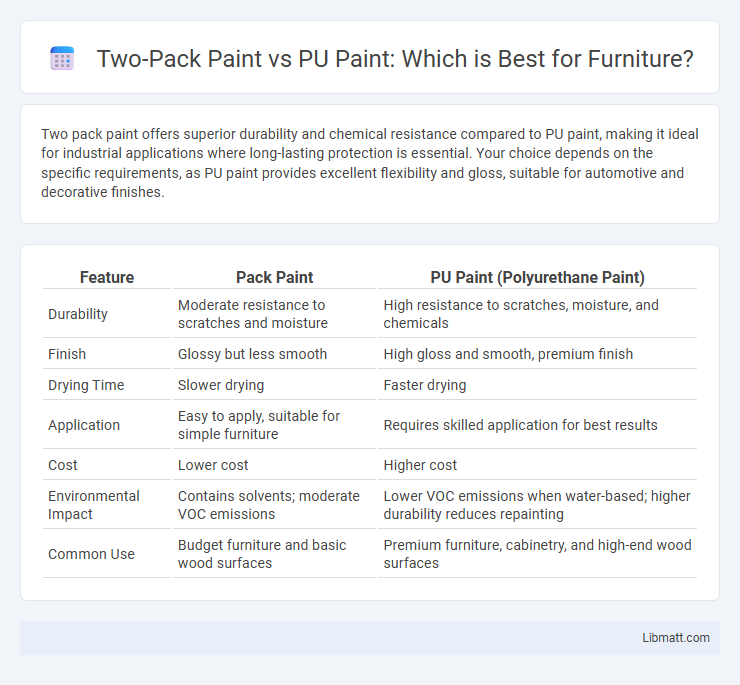

Table of Comparison

| Feature | Pack Paint | PU Paint (Polyurethane Paint) |

|---|---|---|

| Durability | Moderate resistance to scratches and moisture | High resistance to scratches, moisture, and chemicals |

| Finish | Glossy but less smooth | High gloss and smooth, premium finish |

| Drying Time | Slower drying | Faster drying |

| Application | Easy to apply, suitable for simple furniture | Requires skilled application for best results |

| Cost | Lower cost | Higher cost |

| Environmental Impact | Contains solvents; moderate VOC emissions | Lower VOC emissions when water-based; higher durability reduces repainting |

| Common Use | Budget furniture and basic wood surfaces | Premium furniture, cabinetry, and high-end wood surfaces |

Introduction to Two Pack Paint and PU Paint

Two Pack Paint consists of a resin and a hardener that chemically react to form a durable and glossy finish ideal for automotive and industrial applications. PU Paint, a type of Two Pack Paint, uses polyurethane as its base, offering superior flexibility, UV resistance, and chemical durability compared to traditional two pack systems. Choosing Your paint depends on the specific requirements for hardness, environmental resistance, and surface finish desired for the project.

Composition and Chemical Structure

Two-pack paint consists of a resin and a hardener that chemically react to form a durable, cross-linked polymer, offering high chemical and abrasion resistance. PU (polyurethane) paint is based on polyurethane polymers, featuring flexible urethane chains that provide excellent elasticity and UV resistance. Your choice depends on whether you prioritize chemical strength from two-pack paints or flexibility and weather resistance typical of PU coatings.

Application Methods and Techniques

Two pack paint requires precise mixing of resin and hardener before application, typically using spray guns to ensure a smooth, durable finish ideal for automotive and industrial surfaces. PU paint also benefits from spray application but is more versatile, allowing for brush or roller techniques on various substrates, including wood and metal. Proper surface preparation and controlled environmental conditions are critical for both paints to achieve optimal adhesion and curing performance.

Durability and Wear Resistance

Two-pack paint offers superior durability and wear resistance due to its chemical curing process, which creates a hard, tough coating ideal for high-traffic or industrial applications. PU paint, formulated with polyurethane, provides excellent flexibility and resistance to abrasion, chemicals, and UV radiation, enhancing long-term performance in outdoor and automotive environments. Both coatings deliver robust protection, but two-pack paint typically excels in hardness, while PU paint balances durability with elasticity.

Surface Finish and Aesthetics

Two pack paint offers a highly durable, glossy surface finish that enhances the color depth and provides excellent resistance to scratches and chemicals, ideal for automotive and industrial applications. PU paint (polyurethane) delivers a smooth, flexible finish with superior UV resistance and a vibrant appearance, making it perfect for outdoor furniture and decorative surfaces. Your choice depends on whether you prioritize hardness and durability (two pack) or elasticity and color retention (PU paint).

Drying and Curing Times

Two pack paint typically dries within 30 minutes to an hour and cures fully in 24 to 48 hours, offering faster turnaround times compared to PU paint. PU paint requires longer drying times, usually around 2 to 4 hours, and may take up to 7 days to cure completely, providing superior durability and chemical resistance. Understanding these drying and curing times helps you choose the right coating based on your project's time constraints and performance needs.

Environmental and Health Considerations

Two pack paint contains isocyanates and solvents that can release harmful VOCs, posing respiratory risks and requiring proper ventilation and protective gear during application. PU paint also emits VOCs but typically offers lower toxicity and better environmental resistance, making it a safer option for both your health and the environment. Choosing PU paint reduces exposure to hazardous chemicals while ensuring durable, eco-friendlier finishes.

Cost Comparison and Value for Money

Two pack paint generally costs more upfront than PU (Polyurethane) paint but offers superior durability and chemical resistance, making it a cost-effective choice for long-term projects. PU paint provides good gloss and flexibility at a lower price, ideal for budget-conscious applications requiring moderate wear resistance. Your decision should weigh initial expenses against the expected lifespan and maintenance frequency to ensure optimal value for money.

Typical Use Cases and Industry Applications

Two-pack paint, known for its chemical resistance and durability, is commonly used in automotive refinishing, industrial equipment, and heavy machinery coatings where strong adhesion and resistance to chemicals and abrasion are critical. PU paint (polyurethane paint) excels in applications requiring flexibility, UV resistance, and a high-gloss finish, making it popular in automotive topcoats, wood furniture, and aerospace industries. Both coatings offer robust protection, but two-pack paint suits high-performance industrial environments while PU paint is preferred for aesthetic finishes combined with durability in consumer goods.

Conclusion: Choosing Between Two Pack Paint and PU Paint

Choosing between two pack paint and PU paint depends on specific project requirements and durability needs. Two pack paint offers superior chemical resistance and hardness, making it ideal for industrial applications, while PU paint provides excellent flexibility and UV resistance suited for automotive and exterior surfaces. Evaluating factors such as environmental exposure, surface type, and desired finish quality ensures the optimal paint selection.

two pack paint vs PU paint Infographic

libmatt.com

libmatt.com