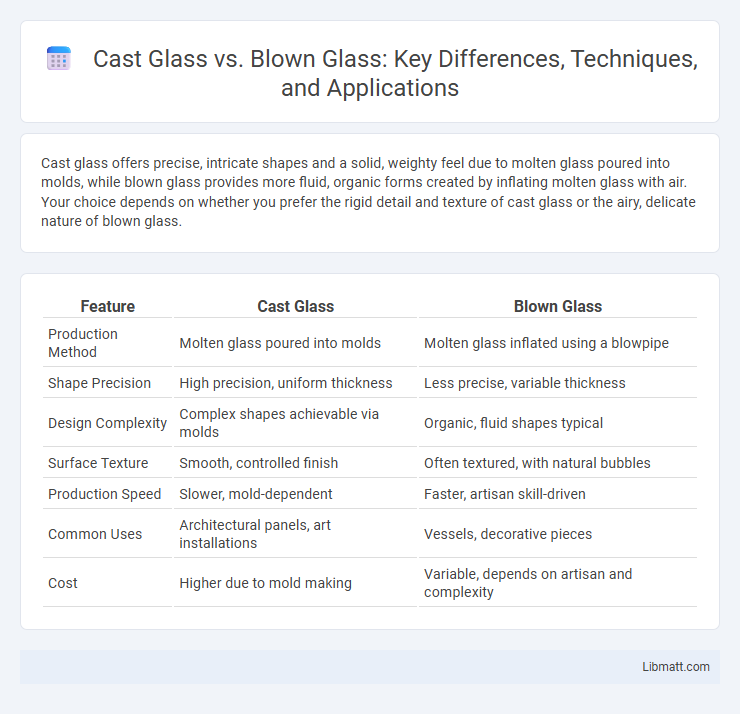

Cast glass offers precise, intricate shapes and a solid, weighty feel due to molten glass poured into molds, while blown glass provides more fluid, organic forms created by inflating molten glass with air. Your choice depends on whether you prefer the rigid detail and texture of cast glass or the airy, delicate nature of blown glass.

Table of Comparison

| Feature | Cast Glass | Blown Glass |

|---|---|---|

| Production Method | Molten glass poured into molds | Molten glass inflated using a blowpipe |

| Shape Precision | High precision, uniform thickness | Less precise, variable thickness |

| Design Complexity | Complex shapes achievable via molds | Organic, fluid shapes typical |

| Surface Texture | Smooth, controlled finish | Often textured, with natural bubbles |

| Production Speed | Slower, mold-dependent | Faster, artisan skill-driven |

| Common Uses | Architectural panels, art installations | Vessels, decorative pieces |

| Cost | Higher due to mold making | Variable, depends on artisan and complexity |

Introduction to Cast Glass and Blown Glass

Cast glass involves melting glass into molds to create solid, often thick and detailed shapes characterized by precise edges and varied textures, while blown glass is crafted by inflating molten glass into hollow forms using a blowpipe, allowing for delicate, lightweight, and fluid designs. The casting process suits architectural and sculptural works requiring substantial thickness and durability, whereas blown glass is favored for decorative and functional items like vases and ornaments, emphasizing transparency and intricate shapes. Understanding these techniques helps you appreciate the distinct artistic and practical applications each glass form offers.

Defining Cast Glass: Techniques and Processes

Cast glass is created by melting glass chunks and pouring the molten material into molds, allowing it to cool and solidify into specific shapes and textures. Techniques include kiln casting, where glass is heated slowly in a kiln to fill detailed molds, and pate de verre, involving finely crushed glass packed into a mold and fused at lower temperatures. This process results in thicker, more solid pieces with varied translucency and intricate surface details compared to the more fluid and delicate forms achieved with blown glass.

Understanding Blown Glass: Methods and Tradition

Blown glass involves shaping molten glass by inflating it through a blowpipe, a technique dating back to the 1st century BC that allows for intricate, lightweight creations with unique textures. This traditional method requires skillful manipulation of temperature and air pressure, producing diverse forms from delicate vases to large art pieces. Your appreciation of blown glass deepens when you understand the craftsmanship and historical legacy behind each handcrafted item.

Key Differences Between Cast and Blown Glass

Cast glass is created by pouring molten glass into a mold, resulting in thicker, more solid pieces with intricate shapes and textures, while blown glass is formed by inflating molten glass into a bubble using a blowpipe, producing lighter, more delicate, and hollow objects. Cast glass allows for greater control over thickness and detailed surface patterns, making it ideal for sculptural and architectural applications, whereas blown glass offers dynamic, thin-walled forms suited for functional items like vases and glassware. Your choice between cast and blown glass depends on the desired strength, shape complexity, and aesthetic qualities.

Artistic Applications: Cast vs. Blown Glass Creations

Cast glass allows artists to create intricate, three-dimensional sculptures with precise detail and texture, making it ideal for architectural and decorative art pieces. Blown glass excels in producing fluid, organic forms with vibrant color gradients and dynamic shapes, perfect for functional art like vases and ornamental objects. Both techniques offer unique artistic applications, with cast glass emphasizing solidity and form, while blown glass highlights fluidity and expression.

Structural and Functional Properties of Each Technique

Cast glass features a denser, more uniform structure due to molten glass being poured into molds, resulting in increased strength and excellent thermal insulation, suitable for architectural applications. Blown glass exhibits a lighter, more flexible structure with variable wall thickness, providing greater elasticity and intricate shapes ideal for decorative and functional art pieces. The functional properties of cast glass prioritize durability and load-bearing capacity, while blown glass emphasizes aesthetic versatility and delicate craftsmanship.

Aesthetic Qualities: Textures, Forms, and Finishes

Cast glass offers rich textures and complex forms due to its mold-based creation process, resulting in surfaces that can be smooth, rippled, or intricately patterned with a weighty, solid appearance. Blown glass, by contrast, is characterized by its fluid, organic shapes and delicate, translucent finishes that emphasize lightness and translucency. Choosing between these methods impacts Your aesthetic preferences, as cast glass provides a sculptural and tactile quality, while blown glass showcases elegance through its airy and seamless contours.

Cost and Accessibility: Comparing Cast and Blown Glass

Cast glass typically incurs higher production costs due to the specialized molds and longer cooling times required, making it less accessible for mass production compared to blown glass. Blown glass offers greater affordability and accessibility because its creation process is faster, utilizes fewer resources, and can be produced in larger quantities. Artists and manufacturers often prefer blown glass for cost-effective projects, while cast glass remains favored for intricate, high-end designs despite its expense.

Sustainability and Environmental Considerations

Cast glass production typically consumes more energy due to prolonged heating and cooling cycles, resulting in a higher carbon footprint compared to blown glass, which uses a more direct heating process. Blown glass often supports sustainable practices by enabling smaller batch production, reducing material waste and energy consumption. Recycling options exist for both techniques, but blown glass benefits from easier reuse and reshaping, enhancing its environmental advantages.

Choosing Between Cast Glass and Blown Glass for Your Project

Choosing between cast glass and blown glass depends on your project's design complexity and functional requirements. Cast glass offers precise shapes and textured surfaces ideal for architectural installations, while blown glass excels in creating delicate, intricate forms suited for decorative art pieces. Consider the durability, production time, and cost factors of cast glass's mold-based process versus the artisanal techniques of blown glass when making your decision.

Cast glass vs blown glass Infographic

libmatt.com

libmatt.com