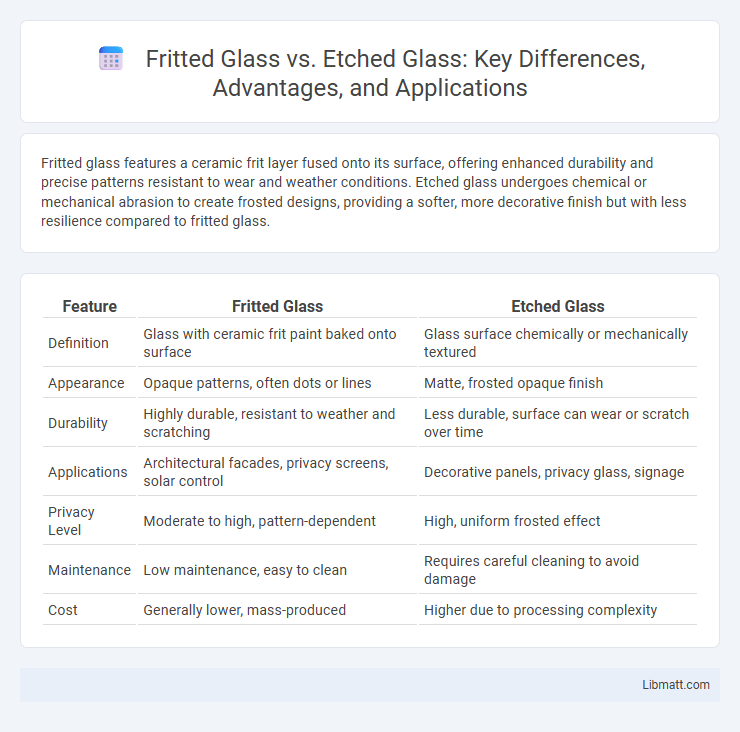

Fritted glass features a ceramic frit layer fused onto its surface, offering enhanced durability and precise patterns resistant to wear and weather conditions. Etched glass undergoes chemical or mechanical abrasion to create frosted designs, providing a softer, more decorative finish but with less resilience compared to fritted glass.

Table of Comparison

| Feature | Fritted Glass | Etched Glass |

|---|---|---|

| Definition | Glass with ceramic frit paint baked onto surface | Glass surface chemically or mechanically textured |

| Appearance | Opaque patterns, often dots or lines | Matte, frosted opaque finish |

| Durability | Highly durable, resistant to weather and scratching | Less durable, surface can wear or scratch over time |

| Applications | Architectural facades, privacy screens, solar control | Decorative panels, privacy glass, signage |

| Privacy Level | Moderate to high, pattern-dependent | High, uniform frosted effect |

| Maintenance | Low maintenance, easy to clean | Requires careful cleaning to avoid damage |

| Cost | Generally lower, mass-produced | Higher due to processing complexity |

Introduction to Fritted Glass and Etched Glass

Fritted glass features a ceramic enamel fused onto the surface during manufacturing, offering durability and customizable patterns for reduced glare and solar heat. Etched glass is created by acid or sandblasting processes to produce frosted, opaque designs that enhance privacy and aesthetic appeal. Understanding these differences helps you select the ideal glass type for your architectural or decorative needs.

Understanding Fritted Glass: Composition and Manufacturing

Fritted glass is created by fusing powdered glass, known as frit, onto a glass surface through high-temperature firing, resulting in a durable, textured coating that enhances light diffusion and reduces glare. This manufacturing process involves carefully controlling the size and distribution of the frit particles to achieve specific aesthetic and functional properties, such as improved thermal insulation and privacy. Unlike etched glass, which uses acid or abrasive techniques to create patterns by removing surface layers, fritted glass's composition integrates into the glass surface, providing greater longevity and resistance to wear.

Etched Glass: Techniques and Applications

Etched glass involves creating intricate designs by using acid, sandblasting, or laser engraving techniques to remove the surface layer, resulting in a frosted appearance. Common applications include privacy windows, decorative panels, and signage in residential and commercial spaces. This technique allows for high customization and detailed artwork, enhancing both aesthetic appeal and functionality.

Key Visual Differences: Fritted vs Etched Glass

Fritted glass features a ceramic enamel pattern fused onto the surface through high-temperature baking, creating distinct, durable designs that can be opaque or translucent, while etched glass is produced by acid or sandblasting techniques, resulting in a matte, frosted appearance with softer, diffuse patterns. Fritted glass typically shows sharp, geometric or custom patterns with clear edges, whereas etched glass offers more subtle, uniform textures without crisp lines. Your choice depends on whether you prefer bold, well-defined visuals or gentle, understated aesthetics for architectural or decorative applications.

Durability and Maintenance Comparison

Fritted glass features a durable ceramic frit coating that withstands harsh weather and resists scratches better than etched glass, making it ideal for high-traffic or outdoor applications. Etched glass, created by acid etching or sandblasting, offers a softer, matte finish but is more prone to surface wear and requires gentle cleaning to maintain its appearance. Your choice should consider the long-term maintenance effort, with fritted glass demanding less frequent upkeep due to its robust coating.

Light Diffusion and Privacy Capabilities

Fritted glass features ceramic patterns baked onto the surface, providing superior light diffusion while maintaining partial transparency, making it ideal for balanced privacy and natural light. Etched glass uses acid or sandblasting techniques to create a frosted, translucent surface that maximizes privacy by obscuring clear views but can reduce the amount of light passing through. Both materials enhance privacy, with fritted glass offering more nuanced light control and etched glass delivering greater opacity for concealment.

Cost and Installation Considerations

Fritted glass typically involves screen-printed ceramic frit, making it more expensive due to the durability and precision of the manufacturing process, while etched glass generally incurs lower costs as it uses acid or sandblasting techniques. Installation of fritted glass requires careful handling to preserve the ceramic coating, often necessitating professional expertise, whereas etched glass is lighter and easier to install, allowing for quicker and more flexible application. Your choice depends on budget constraints and installation complexity, with fritted glass offering long-term durability and etched glass providing cost-effective versatility.

Common Uses in Architecture and Interior Design

Fritted glass is commonly used in architectural applications for energy efficiency and safety, including facades, skylights, and sunshades, where its patterned ceramic coating reduces glare and solar heat gain. Etched glass enhances interior design through decorative purposes, often found in partitions, doors, and bathroom windows, providing privacy while allowing light transmission. Your choice between fritted and etched glass depends on whether you prioritize functional performance or aesthetic texture in your space.

Environmental Impact and Sustainability

Fritted glass features ceramic frit baked onto its surface, creating patterns that reduce solar heat gain and improve energy efficiency in buildings, contributing to lower carbon footprints. Etched glass, produced by acid or sandblasting processes, often requires more energy-intensive chemicals and results in less energy performance enhancement. The durability and longevity of fritted glass also support sustainability by reducing the need for replacements and minimizing material waste over time.

Choosing Between Fritted and Etched Glass: Factors to Consider

When choosing between fritted and etched glass, consider factors such as durability, light diffusion, and aesthetic appeal. Fritted glass offers superior durability with its baked-in ceramic frit pattern, providing enhanced UV resistance and reduced glare, ideal for exterior applications. Etched glass delivers a softer, translucent finish created through acid or sandblasting, perfect for decorative interiors requiring privacy without compromising natural light.

Fritted glass vs etched glass Infographic

libmatt.com

libmatt.com