Chemically strengthened glass undergoes an ion-exchange process where smaller ions in the glass are replaced by larger ones, resulting in higher surface compression and superior scratch resistance compared to thermally strengthened glass. Your choice depends on the desired strength, optical clarity, and durability, with chemically strengthened glass offering enhanced toughness and thermal stability.

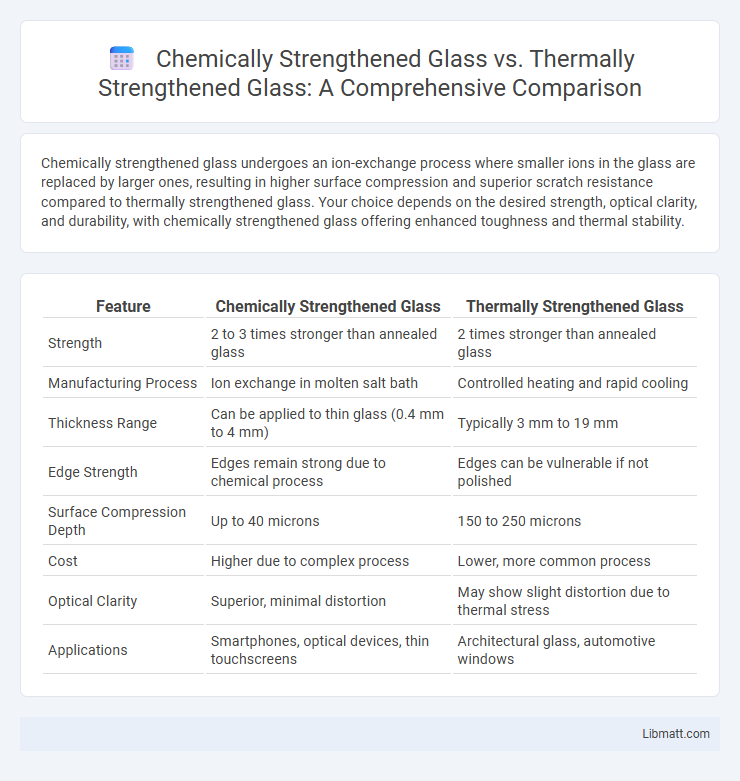

Table of Comparison

| Feature | Chemically Strengthened Glass | Thermally Strengthened Glass |

|---|---|---|

| Strength | 2 to 3 times stronger than annealed glass | 2 times stronger than annealed glass |

| Manufacturing Process | Ion exchange in molten salt bath | Controlled heating and rapid cooling |

| Thickness Range | Can be applied to thin glass (0.4 mm to 4 mm) | Typically 3 mm to 19 mm |

| Edge Strength | Edges remain strong due to chemical process | Edges can be vulnerable if not polished |

| Surface Compression Depth | Up to 40 microns | 150 to 250 microns |

| Cost | Higher due to complex process | Lower, more common process |

| Optical Clarity | Superior, minimal distortion | May show slight distortion due to thermal stress |

| Applications | Smartphones, optical devices, thin touchscreens | Architectural glass, automotive windows |

Introduction to Strengthened Glass Types

Chemically strengthened glass is produced by ion exchange, where smaller sodium ions are replaced by larger potassium ions, creating a compressive stress layer that enhances surface strength. Thermally strengthened glass undergoes controlled heating and rapid cooling, inducing surface compression and increased mechanical strength, though it remains less strong than chemically strengthened glass. Both types offer improved resistance to impact and thermal stress compared to untreated annealed glass, with chemical strengthening providing higher strength and better edge durability.

Overview of Chemically Strengthened Glass

Chemically strengthened glass undergoes an ion-exchange process where smaller sodium ions in the glass surface are replaced by larger potassium ions, creating compressive stress that enhances durability and scratch resistance. This method achieves higher surface strength and resistance to damage compared to thermally strengthened glass, which is hardened through rapid cooling. The enhanced structural integrity of chemically strengthened glass makes it ideal for applications requiring thin, lightweight, and high-performance glass panels.

Overview of Thermally Strengthened Glass

Thermally strengthened glass undergoes a controlled heating process followed by rapid cooling, creating surface compressive stresses that enhance its strength compared to annealed glass. This glass typically achieves a tensile strength around 100 MPa, making it more resistant to impacts and thermal stress but less strong than chemically strengthened glass, which can reach over 700 MPa. Common applications include architectural facades, automotive windows, and glass balustrades where moderate strength and improved safety are required without the higher cost of chemical strengthening.

Manufacturing Processes: Chemical vs Thermal Strengthening

Chemical strengthening of glass involves immersing the glass in a molten salt bath, typically potassium nitrate, where smaller sodium ions are replaced by larger potassium ions from the salt, creating a compressive stress layer on the surface. Thermal strengthening, on the other hand, heats the glass to a temperature just below its melting point before rapidly cooling it with air jets, inducing compressive stresses through controlled cooling rates. Your choice between chemically and thermally strengthened glass depends on the required surface strength, durability, and the complexity of the glass shaping process.

Comparative Strength and Durability

Chemically strengthened glass offers superior surface compressive stress, typically around 700 MPa, resulting in higher resistance to scratches and impact compared to thermally strengthened glass, which exhibits compressive stress near 100-200 MPa. Thermally strengthened glass undergoes rapid cooling, enhancing overall strength and thermal resistance but remains more prone to surface damage. The deeper compression layer in chemically strengthened glass translates to improved durability and longevity in demanding applications like touchscreen devices and architectural glazing.

Applications in Modern Industries

Chemically strengthened glass offers exceptional surface compression, making it ideal for smartphones, tablets, and wearable devices where thinness and durability are critical. Thermally strengthened glass, with its higher bending strength, is widely used in architectural applications such as building facades, automotive windows, and glass railings. Both types enhance safety and performance, but chemical strengthening excels in precision electronics while thermal strengthening dominates structural and safety glass markets.

Cost and Production Efficiency

Chemically strengthened glass typically incurs higher costs due to the complex ion-exchange process requiring specialized chemicals and longer production times. Thermally strengthened glass benefits from faster production through controlled reheating and quenching, resulting in lower manufacturing expenses. Despite higher initial costs, chemically strengthened glass offers superior surface compression and strength, potentially reducing long-term maintenance and replacement costs.

Visual Clarity and Aesthetics

Chemically strengthened glass offers superior visual clarity compared to thermally strengthened glass due to its uniform surface compression and minimal distortion, making it ideal for applications requiring pristine aesthetics. Thermally strengthened glass often exhibits slight warping or roller wave patterns from the tempering process, which can affect transparency and visual quality. Therefore, chemically strengthened glass is preferred in high-end architectural and display applications where optical performance and aesthetic perfection are critical.

Safety, Breakage, and Fragmentation Patterns

Chemically strengthened glass undergoes ion exchange, enhancing surface compressive stress, resulting in superior resistance to scratches and higher tensile strength compared to thermally strengthened glass, which is tempered through rapid cooling. Chemically strengthened glass typically breaks with fewer, larger fragments, reducing the risk of injury, whereas thermally strengthened glass shatters into smaller, blunt granules, offering greater safety through minimized sharp edges. In terms of safety performance, chemically strengthened glass provides better durability against incidents involving high impact and improves overall longevity in harsh environments.

Choosing the Ideal Strengthened Glass

Chemically strengthened glass features enhanced surface compression achieved through ion exchange, resulting in higher strength and superior scratch resistance compared to thermally strengthened glass, which gains toughness from controlled thermal tempering processes. When choosing the ideal strengthened glass, consider factors such as the required durability, thickness limitations, optical clarity, and budget constraints, as chemically strengthened glass offers thinner profiles with better edge strength and visual quality but at a higher cost. Applications demanding maximum safety, impact resistance, and aesthetic appeal often benefit from chemically strengthened glass, whereas thermally strengthened glass remains a cost-effective option for general architectural usage.

Chemically strengthened glass vs thermally strengthened glass Infographic

libmatt.com

libmatt.com