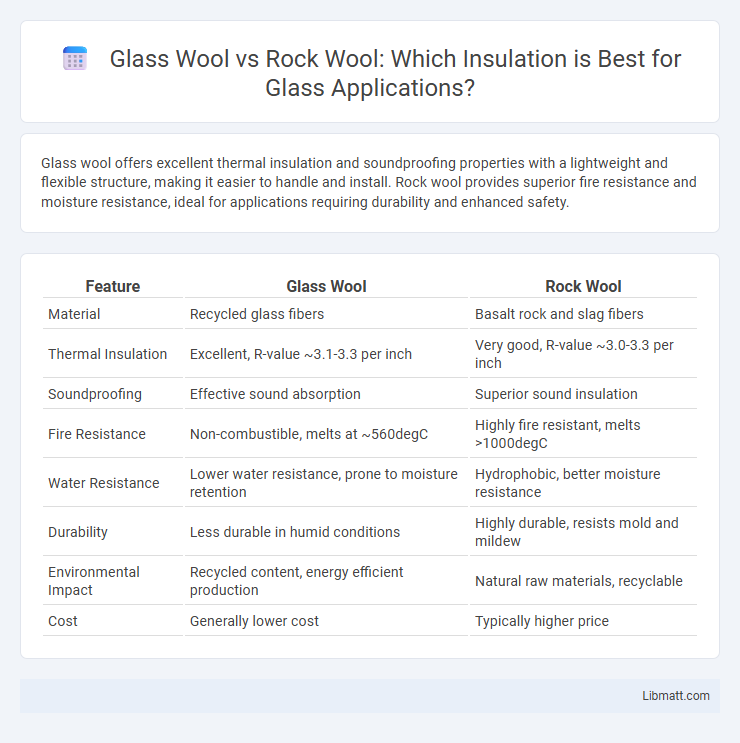

Glass wool offers excellent thermal insulation and soundproofing properties with a lightweight and flexible structure, making it easier to handle and install. Rock wool provides superior fire resistance and moisture resistance, ideal for applications requiring durability and enhanced safety.

Table of Comparison

| Feature | Glass Wool | Rock Wool |

|---|---|---|

| Material | Recycled glass fibers | Basalt rock and slag fibers |

| Thermal Insulation | Excellent, R-value ~3.1-3.3 per inch | Very good, R-value ~3.0-3.3 per inch |

| Soundproofing | Effective sound absorption | Superior sound insulation |

| Fire Resistance | Non-combustible, melts at ~560degC | Highly fire resistant, melts >1000degC |

| Water Resistance | Lower water resistance, prone to moisture retention | Hydrophobic, better moisture resistance |

| Durability | Less durable in humid conditions | Highly durable, resists mold and mildew |

| Environmental Impact | Recycled content, energy efficient production | Natural raw materials, recyclable |

| Cost | Generally lower cost | Typically higher price |

Introduction to Glass Wool and Rock Wool

Glass wool and rock wool are two common types of mineral wool insulation known for their thermal and acoustic properties. Glass wool is made from recycled glass and sand melted into fibers, while rock wool is derived from natural basalt or diabase stone heated and spun into fibrous material. Both materials offer fire resistance and sound absorption, but differ in composition and environmental impact.

Composition and Material Differences

Glass wool is primarily made from recycled glass and sand, melted and spun into fine fibers, resulting in a lightweight insulation material with excellent thermal and acoustic properties. Rock wool, also known as stone wool, is produced by melting basalt or diabase rocks at high temperatures and spinning the molten rock into fibers, providing superior fire resistance and soundproofing compared to glass wool. Both materials offer distinct advantages based on their composition, with glass wool excelling in cost-effectiveness and flexibility, while rock wool is favored for durability and higher temperature tolerance.

Thermal Insulation Performance

Glass wool and rock wool both provide excellent thermal insulation, but glass wool typically offers a slightly higher R-value per inch, enhancing energy efficiency in temperature regulation. Rock wool excels in withstanding higher temperatures and maintaining insulating properties under extreme heat, making it suitable for fire-resilient applications. Your choice depends on specific insulation needs, balancing thermal performance with fire resistance.

Soundproofing Capabilities

Glass wool offers excellent sound absorption, making it effective for reducing airborne noise in residential and commercial buildings. Rock wool, with its higher density and rigidity, excels at both sound absorption and soundproofing by blocking airborne and impact noise more efficiently. For your project, choosing rock wool can provide superior soundproofing capabilities, especially in environments requiring enhanced noise control.

Fire Resistance Comparison

Glass wool and rock wool both offer excellent fire resistance, but rock wool outperforms glass wool due to its higher melting point, typically around 1170degC compared to glass wool's 540degC. This makes rock wool non-combustible and capable of providing superior fire insulation in high-temperature environments. You can rely on rock wool for enhanced fire safety in construction projects requiring stringent fire resistance standards.

Moisture and Water Resistance

Glass wool exhibits lower moisture absorption compared to rock wool, making it more resistant to water damage and maintaining its insulating properties in damp environments. Rock wool, although denser and more durable, tends to absorb more moisture, which can reduce its thermal efficiency and promote mold growth if not properly protected. Both materials require vapor barriers for optimal performance in high-humidity settings to prevent water intrusion and maintain insulation integrity.

Installation and Handling

Glass wool offers lightweight, flexible batts that simplify cutting and fitting around irregular spaces, enhancing ease of installation. Rock wool is denser and more rigid, requiring sturdier support and precise measurements during handling to avoid gaps. Both materials demand protective gear during installation due to their fibrous nature, but glass wool generally produces less skin irritation than rock wool.

Environmental Impact and Sustainability

Glass wool is made from recycled glass and sand, making it a more sustainable option with a lower carbon footprint compared to rock wool, which primarily consists of natural volcanic rock and industrial slag. Both materials are recyclable and contribute to energy efficiency in buildings, but glass wool typically requires less energy during production. Rock wool offers superior fire resistance and durability, which can enhance building longevity and reduce long-term environmental impact despite its higher initial energy consumption.

Cost and Availability

Glass wool typically offers a lower upfront cost compared to rock wool, making it a budget-friendly choice for many insulation projects. Rock wool, however, tends to be more widely available in various densities and thicknesses, providing more options depending on your specific insulation needs. Choosing between glass wool and rock wool will depend on balancing your budget constraints with the availability of materials in your local market.

Applications and Best Use Cases

Glass wool excels in thermal and acoustic insulation for residential walls, attics, and HVAC systems due to its lightweight and flexible properties. Rock wool is preferred for fire-resistant applications, industrial insulation, and soundproofing in commercial buildings because of its high density and superior fire resistance. Both materials are suitable for insulation, but glass wool is best for general thermal efficiency, while rock wool is ideal in environments requiring enhanced fire protection and durability.

glass wool vs rock wool Infographic

libmatt.com

libmatt.com