Float glass offers a smooth, flat surface ideal for windows and mirrors due to its uniform thickness and clarity, while rolled glass features a textured surface created by passing molten glass through rollers, making it perfect for decorative applications and privacy solutions. Choosing between float glass and rolled glass depends on whether your project prioritizes transparency and precision or texture and light diffusion.

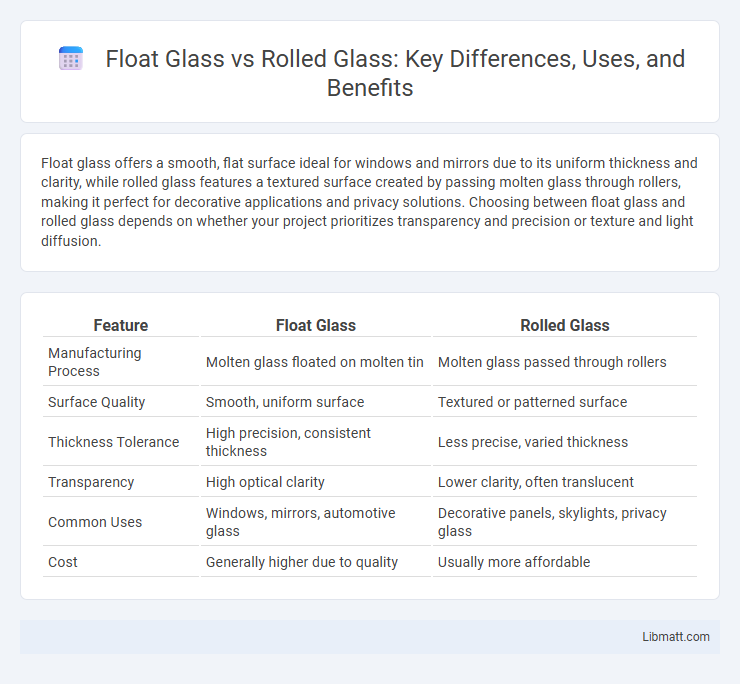

Table of Comparison

| Feature | Float Glass | Rolled Glass |

|---|---|---|

| Manufacturing Process | Molten glass floated on molten tin | Molten glass passed through rollers |

| Surface Quality | Smooth, uniform surface | Textured or patterned surface |

| Thickness Tolerance | High precision, consistent thickness | Less precise, varied thickness |

| Transparency | High optical clarity | Lower clarity, often translucent |

| Common Uses | Windows, mirrors, automotive glass | Decorative panels, skylights, privacy glass |

| Cost | Generally higher due to quality | Usually more affordable |

Introduction to Float Glass and Rolled Glass

Float glass is produced by floating molten glass on a bed of molten metal, typically tin, resulting in a smooth, uniform thickness and clarity ideal for windows and mirrors. Rolled glass is made by passing molten glass through heavy rollers, creating textured or patterned surfaces often used for decorative or privacy purposes. Your choice between float and rolled glass depends on whether clarity or texture is a priority for your application.

Manufacturing Processes Compared

Float glass is produced by floating molten glass on a bed of molten tin, creating a smooth, uniform surface with consistent thickness and high optical clarity. Rolled glass is made by passing molten glass through rollers, resulting in textured or patterned surfaces and variable thickness, often used for decorative or privacy purposes. Your choice depends on the required clarity, texture, and application in architectural or automotive glazing.

Key Differences in Physical Properties

Float glass boasts a smooth, uniform surface with consistent thickness due to its manufacturing process, providing superior optical clarity and strength compared to rolled glass. Rolled glass features a textured, wavy surface caused by pressing molten glass between rollers, resulting in less optical clarity and variable thickness. Your choice between float and rolled glass will depend on the specific requirements for transparency, strength, and texture in your application.

Optical Clarity and Appearance

Float glass offers superior optical clarity due to its smooth, even surfaces created by floating molten glass on a bed of molten tin, resulting in minimal distortion and high transparency. Rolled glass, produced by passing molten glass through rollers, has a textured or patterned surface that causes light diffusion, reducing clarity and creating a frosted or opaque appearance. This makes float glass ideal for applications requiring clear, undistorted views, while rolled glass suits decorative or privacy-focused uses.

Strength and Durability

Float glass offers superior strength and durability compared to rolled glass due to its uniform thickness and smooth surface, which reduce stress points and resistance to impact. Rolled glass, produced by passing molten glass between rollers, often contains surface imperfections and variable thickness, making it more prone to breakage under stress. The manufacturing process of float glass results in enhanced structural integrity, making it the preferred choice for applications requiring high strength and durability.

Common Applications of Each Type

Float glass is commonly used in architectural windows, automotive windshields, and furniture due to its smooth, uniform surface and high optical clarity. Rolled glass is often found in decorative applications, such as textured glass panels, shower enclosures, and privacy windows, where its embossed patterns diffuse light and obscure visibility. Both types serve distinct functions, with float glass preferred for clarity and strength, while rolled glass enhances aesthetics and light diffusion.

Cost and Availability

Float glass is generally more cost-effective and widely available compared to rolled glass, making it a preferred choice for many construction and automotive applications. Its uniform thickness and clarity are produced by floating molten glass on a bed of molten metal, ensuring consistent quality at a competitive price. You can easily source float glass in various sizes and thicknesses from most hardware and glass suppliers.

Energy Efficiency and Insulation

Float glass offers superior energy efficiency and insulation compared to rolled glass due to its smooth, uniform surface that enhances thermal performance and reduces heat transfer. The even thickness of float glass allows for better sealing in double-glazed windows, improving insulation properties and lowering energy consumption in buildings. Rolled glass, with its textured surface and inconsistent thickness, typically provides lower thermal resistance and less effective energy conservation.

Sustainability and Environmental Impact

Float glass production generates less energy consumption and fewer greenhouse gas emissions compared to rolled glass due to its more efficient manufacturing process. Recycled float glass can be incorporated at higher rates, reducing raw material extraction and landfill waste, enhancing its sustainability profile. Rolled glass, typically produced through energy-intensive methods with lower recycling rates, tends to have a greater environmental footprint, making float glass the preferred eco-friendly option in construction and design.

Choosing the Right Glass for Your Project

Float glass offers superior clarity and smooth surfaces, making it ideal for architectural and automotive applications where visual quality is crucial. Rolled glass features textured patterns that provide privacy and diffuse light, suitable for decorative or privacy-enhancing installations. Your decision should consider whether optical clarity or surface texture best aligns with your project's functional and aesthetic requirements.

float glass vs rolled glass Infographic

libmatt.com

libmatt.com