Borosilicate glass offers superior thermal resistance and chemical durability compared to soda-lime glass, making it ideal for laboratory equipment and cookware. Your choice depends on needing heat resistance or cost-effectiveness, as soda-lime glass is more affordable but less resistant to temperature changes.

Table of Comparison

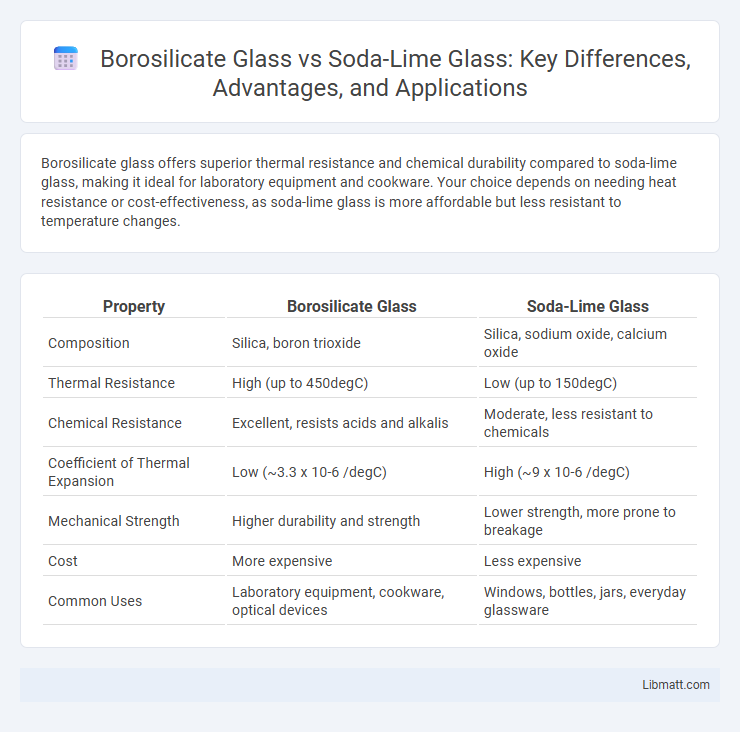

| Property | Borosilicate Glass | Soda-Lime Glass |

|---|---|---|

| Composition | Silica, boron trioxide | Silica, sodium oxide, calcium oxide |

| Thermal Resistance | High (up to 450degC) | Low (up to 150degC) |

| Chemical Resistance | Excellent, resists acids and alkalis | Moderate, less resistant to chemicals |

| Coefficient of Thermal Expansion | Low (~3.3 x 10-6 /degC) | High (~9 x 10-6 /degC) |

| Mechanical Strength | Higher durability and strength | Lower strength, more prone to breakage |

| Cost | More expensive | Less expensive |

| Common Uses | Laboratory equipment, cookware, optical devices | Windows, bottles, jars, everyday glassware |

Introduction to Borosilicate and Soda-Lime Glass

Borosilicate glass contains about 12-13% boron trioxide, which gives it superior thermal resistance and chemical durability compared to soda-lime glass, primarily composed of silica, soda, and lime. Soda-lime glass is the most common glass type found in windows and bottles, offering affordability and ease of manufacturing but lower resistance to thermal shock. Your choice between borosilicate and soda-lime glass should consider factors like heat resistance, durability, and application requirements.

Chemical Composition Differences

Borosilicate glass contains silica and boron trioxide, which provide superior thermal resistance and chemical durability compared to soda-lime glass, primarily composed of silica, sodium oxide, and calcium oxide. The presence of boron in borosilicate glass reduces its coefficient of thermal expansion, making it less prone to cracking under temperature changes. Your choice of glass should consider these chemical composition differences for applications requiring enhanced heat and chemical resistance.

Manufacturing Processes Compared

Borosilicate glass is manufactured using higher temperature processes and contains boron oxide, which enhances thermal resistance and durability, making it ideal for labware and cookware. Soda-lime glass, produced from sand, soda ash, and limestone at lower temperatures, is more cost-effective but less resistant to thermal shock. Your choice depends on the need for heat tolerance versus manufacturing cost efficiency.

Thermal Resistance and Heat Tolerance

Borosilicate glass exhibits superior thermal resistance with a low coefficient of thermal expansion (approximately 3.3 x 10-6 /degC), enabling it to withstand rapid temperature changes up to 450degC without cracking. In contrast, soda-lime glass has a higher thermal expansion coefficient (around 9 x 10-6 /degC) and lower heat tolerance, typically tolerating temperatures up to 150degC before deformation or breakage occurs. These properties make borosilicate glass ideal for laboratory equipment and cookware that require exposure to high heat and sudden temperature fluctuations.

Mechanical Strength and Durability

Borosilicate glass exhibits superior mechanical strength and durability compared to soda-lime glass due to its low thermal expansion coefficient, which minimizes stress from temperature fluctuations. Its chemical composition, rich in silica and boron oxide, enhances resistance to mechanical shocks and prevents surface degradation over time. While soda-lime glass is more prone to crack formation and wear under mechanical stress, borosilicate glass maintains structural integrity in demanding environments and industrial applications.

Optical Clarity and Transparency

Borosilicate glass offers superior optical clarity and transparency due to its lower iron content and higher purity, resulting in less color distortion and enhanced light transmission compared to soda-lime glass. Soda-lime glass, commonly used in everyday applications, tends to have a slight greenish tint caused by higher iron levels, which can reduce visual clarity. When your projects demand the highest level of clear, true-to-color visibility, borosilicate glass is the optimal choice for precise optical performance.

Common Applications and Uses

Borosilicate glass is widely used in laboratory equipment, cookware, and high-quality glassware due to its exceptional thermal resistance and durability. Soda-lime glass, the most common glass type, is primarily found in windows, bottles, and everyday containers where cost-effectiveness and ease of manufacturing are key. Understanding the differences between these materials helps you select the right glass for applications that demand either heat resistance or affordability.

Cost and Availability Analysis

Borosilicate glass typically costs more than soda-lime glass due to its enhanced thermal resistance and durability, making it ideal for laboratory and high-performance kitchenware, while soda-lime glass remains the most widely produced and accessible option for everyday use. You can find soda-lime glass in most household products at a lower price point because it benefits from large-scale manufacturing and abundant raw materials. The higher price of borosilicate glass reflects its specialized production process, limiting its availability compared to the mass-produced soda-lime glass.

Environmental Impact and Recyclability

Borosilicate glass generates lower carbon emissions during production due to its durability and thermal resistance, reducing the need for frequent replacements compared to soda-lime glass. Soda-lime glass is more widely recycled because of its higher global recycling infrastructure, but borosilicate glass's specialized composition often leads to challenges in standard recycling processes. Both types contribute to environmental sustainability when properly recycled, yet borosilicate glass's longer lifespan offsets some recycling limitations by minimizing waste generation.

Choosing the Right Glass for Your Needs

Borosilicate glass offers superior thermal resistance and durability, making it ideal for laboratory equipment, cookware, and high-heat applications compared to soda-lime glass, which is more affordable and suitable for everyday use like windows and bottles. Your choice depends on the need for heat tolerance and chemical resistance versus cost-effectiveness and practicality. For tasks involving rapid temperature changes or chemical exposure, borosilicate glass ensures safety and longevity, while soda-lime glass suffices for general household purposes.

borosilicate glass vs soda-lime glass Infographic

libmatt.com

libmatt.com