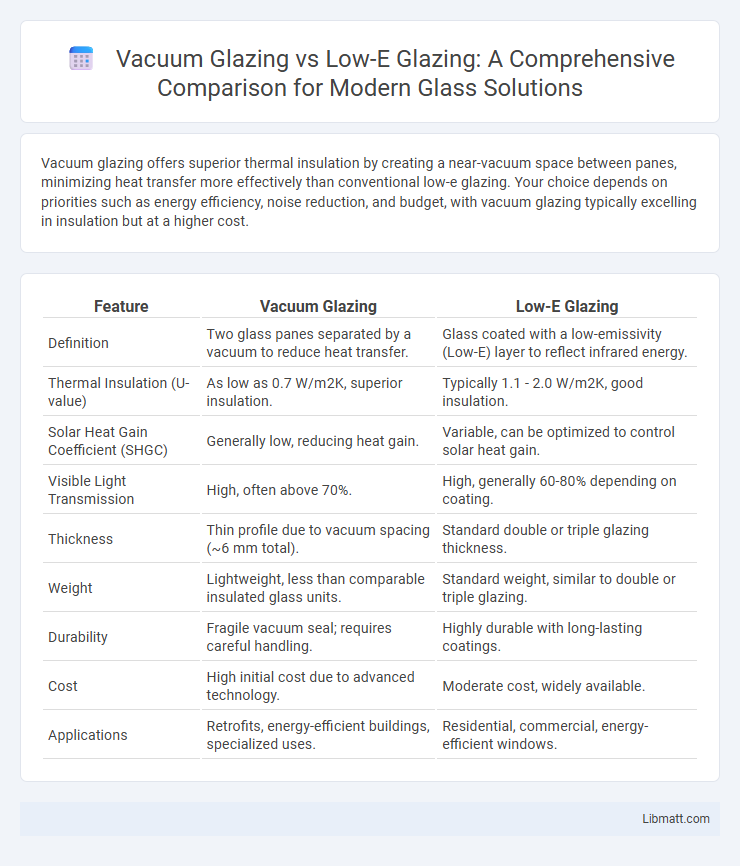

Vacuum glazing offers superior thermal insulation by creating a near-vacuum space between panes, minimizing heat transfer more effectively than conventional low-e glazing. Your choice depends on priorities such as energy efficiency, noise reduction, and budget, with vacuum glazing typically excelling in insulation but at a higher cost.

Table of Comparison

| Feature | Vacuum Glazing | Low-E Glazing |

|---|---|---|

| Definition | Two glass panes separated by a vacuum to reduce heat transfer. | Glass coated with a low-emissivity (Low-E) layer to reflect infrared energy. |

| Thermal Insulation (U-value) | As low as 0.7 W/m2K, superior insulation. | Typically 1.1 - 2.0 W/m2K, good insulation. |

| Solar Heat Gain Coefficient (SHGC) | Generally low, reducing heat gain. | Variable, can be optimized to control solar heat gain. |

| Visible Light Transmission | High, often above 70%. | High, generally 60-80% depending on coating. |

| Thickness | Thin profile due to vacuum spacing (~6 mm total). | Standard double or triple glazing thickness. |

| Weight | Lightweight, less than comparable insulated glass units. | Standard weight, similar to double or triple glazing. |

| Durability | Fragile vacuum seal; requires careful handling. | Highly durable with long-lasting coatings. |

| Cost | High initial cost due to advanced technology. | Moderate cost, widely available. |

| Applications | Retrofits, energy-efficient buildings, specialized uses. | Residential, commercial, energy-efficient windows. |

Introduction to Vacuum Glazing and Low-E Glazing

Vacuum glazing consists of two or more glass panes separated by a vacuum layer that significantly reduces heat transfer and enhances insulation performance, making it ideal for energy-efficient windows. Low-E glazing features a microscopically thin, transparent coating that reflects infrared energy while allowing visible light to pass through, thereby minimizing heat loss and gain. Your choice between vacuum glazing and low-E glazing depends on factors like thermal insulation needs, cost considerations, and specific climate conditions.

How Vacuum Glazing Works

Vacuum glazing works by creating a vacuum between two panes of glass, which significantly reduces heat transfer through conduction and convection, leading to superior thermal insulation compared to traditional low-e glazing. The vacuum layer prevents air molecules from passing heat, while low-e coatings reflect infrared radiation to minimize heat loss. Your energy efficiency improves as vacuum glazing effectively insulates while maintaining slim window profiles.

How Low-E Glazing Works

Low-E glazing works by applying a microscopically thin, transparent coating that reflects infrared heat while allowing visible light to pass through, enhancing energy efficiency. This coating reduces heat transfer, keeping your indoor space warmer in winter and cooler in summer. Unlike vacuum glazing, which uses a vacuum layer to minimize conduction and convection, Low-E glazing primarily targets radiative heat control through selective reflection.

Thermal Insulation Performance Comparison

Vacuum glazing offers superior thermal insulation performance by creating a near-vacuum space between glass panes, drastically reducing heat transfer through conduction and convection compared to traditional low-e glazing. Low-e glazing enhances insulation by reflecting infrared heat with a microscopically thin metallic coating, but it cannot match the ultra-low thermal conductivity of vacuum glazing. Your choice between the two should consider the higher energy efficiency and temperature stability benefits provided by vacuum glazing in extreme climates.

Energy Efficiency and Cost Savings

Vacuum glazing offers superior thermal insulation by creating a near-vacuum space between glass panes, significantly reducing heat transfer and enhancing energy efficiency compared to standard glazing options. Low-e glazing employs a microscopically thin, transparent coating that reflects infrared energy while allowing visible light, effectively reducing heating and cooling costs by minimizing heat loss in winter and heat gain in summer. Choosing vacuum glazing can result in higher upfront investment but delivers substantial long-term cost savings through reduced energy consumption, while low-e glazing provides a more affordable solution with moderate energy efficiency improvements.

Acoustic Insulation: Which Performs Better?

Vacuum glazing offers superior acoustic insulation due to its airless space between glass panes, which significantly reduces sound transmission compared to low-e glazing that relies on a thin metallic coating primarily designed to reflect infrared radiation. The vacuum gap in vacuum glazing minimizes pressure fluctuations, effectively blocking a broader range of sound frequencies, making it ideal for noisy urban environments. Low-e glazing improves energy efficiency and reduces UV rays but generally provides less sound attenuation compared to vacuum glazing's enhanced acoustic performance.

Thickness and Weight Differences

Vacuum glazing typically has a thickness of around 6 to 8 millimeters, which is thinner compared to low-e glazing that generally ranges from 10 to 12 millimeters due to its multiple glass layers and coatings. The lightweight nature of vacuum glazing results from the absence of a thick air gap, making it significantly lighter than low-e glazing, which relies on heavier insulating gas fills between glass panes. Your choice between the two can impact window frame compatibility and overall building weight.

Longevity and Durability

Vacuum glazing offers superior longevity and durability due to its sealed vacuum space that minimizes heat transfer and prevents moisture ingress, ensuring stable thermal performance over decades. Low-e glazing, while effective in reducing energy loss via its metallic coating, may degrade over time when exposed to environmental factors such as UV light and humidity. For Your investment in long-term energy efficiency, vacuum glazing provides a more resilient solution with extended lifespan and reduced maintenance needs.

Installation and Maintenance Considerations

Vacuum glazing requires professional installation due to its delicate sealed edge and precise vacuum space, ensuring long-term performance without gas fill degradation. Low-e glazing is easier to install since it functions like standard double glazing but may need careful handling to avoid damaging the thin metallic coating that enhances energy efficiency. Your choice should account for maintenance differences: vacuum glazing is virtually maintenance-free with excellent durability, while low-e coatings may degrade over time or require replacement to maintain optimum thermal performance.

Choosing the Right Glazing for Your Needs

Vacuum glazing offers superior thermal insulation by creating a near-vacuum space between glass panes, significantly reducing heat transfer and enhancing energy efficiency. Low-e glazing uses a microscopically thin, transparent coating to reflect infrared and ultraviolet light, maintaining natural daylight while minimizing heat loss and gain. Your choice depends on the priority between maximum insulation performance with vacuum glazing or the cost-effectiveness and light control benefits of low-e glazing.

vacuum glazing vs low-e glazing Infographic

libmatt.com

libmatt.com