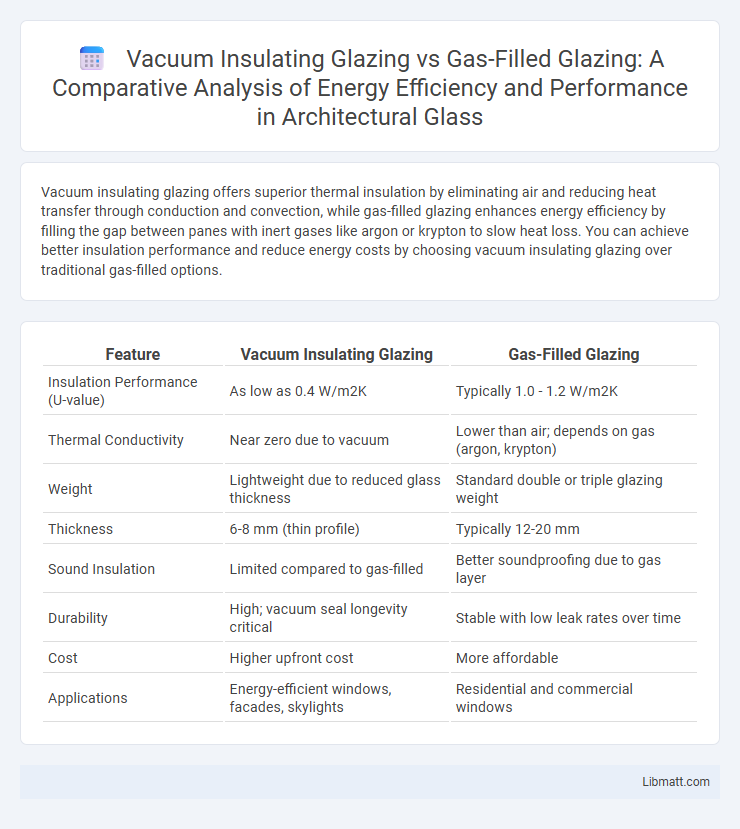

Vacuum insulating glazing offers superior thermal insulation by eliminating air and reducing heat transfer through conduction and convection, while gas-filled glazing enhances energy efficiency by filling the gap between panes with inert gases like argon or krypton to slow heat loss. You can achieve better insulation performance and reduce energy costs by choosing vacuum insulating glazing over traditional gas-filled options.

Table of Comparison

| Feature | Vacuum Insulating Glazing | Gas-Filled Glazing |

|---|---|---|

| Insulation Performance (U-value) | As low as 0.4 W/m2K | Typically 1.0 - 1.2 W/m2K |

| Thermal Conductivity | Near zero due to vacuum | Lower than air; depends on gas (argon, krypton) |

| Weight | Lightweight due to reduced glass thickness | Standard double or triple glazing weight |

| Thickness | 6-8 mm (thin profile) | Typically 12-20 mm |

| Sound Insulation | Limited compared to gas-filled | Better soundproofing due to gas layer |

| Durability | High; vacuum seal longevity critical | Stable with low leak rates over time |

| Cost | Higher upfront cost | More affordable |

| Applications | Energy-efficient windows, facades, skylights | Residential and commercial windows |

Introduction to Vacuum Insulating Glazing and Gas-Filled Glazing

Vacuum insulating glazing uses a near-vacuum layer between glass panes to minimize heat transfer and enhance thermal performance, outperforming traditional gas-filled glazing that relies on inert gases like argon or krypton to reduce conductivity. This technology significantly improves insulation by nearly eliminating convection and conduction, leading to greater energy savings and comfort in buildings. Your choice between vacuum and gas-filled glazing depends on factors such as insulation efficiency, cost, and application requirements.

How Vacuum Insulating Glazing Works

Vacuum insulating glazing works by eliminating air between two panes of glass, creating a near-perfect vacuum that drastically reduces heat transfer through conduction and convection. This vacuum space, typically less than 1 millimeter thick, limits thermal bridging and enhances insulation performance, surpassing gas-filled glazing's heat retention abilities. Specialized edge seals maintain the vacuum environment, ensuring long-term durability and energy efficiency in architectural applications.

Key Features of Gas-Filled Glazing

Gas-filled glazing uses inert gases like argon or krypton between glass panes to improve thermal insulation by reducing heat transfer. Its key features include enhanced energy efficiency, noise reduction, and condensation resistance due to the gas's low thermal conductivity. This glazing technology is widely employed in energy-efficient windows to optimize indoor climate control and reduce heating and cooling costs.

Thermal Performance Comparison

Vacuum insulating glazing offers superior thermal performance by minimizing heat transfer through the removal of air or gas between panes, resulting in near-zero convection and conduction losses. Gas-filled glazing typically uses argon or krypton gas to reduce heat transfer, but its insulating effect is less effective compared to the vacuum's near-perfect thermal barrier. Your choice between vacuum insulating glazing and gas-filled glazing will significantly impact energy efficiency, with vacuum glazing generally providing better insulation and lower U-values.

Energy Efficiency and Cost Savings

Vacuum insulating glazing offers superior energy efficiency by minimizing heat transfer through its near-complete air removal, resulting in lower U-values typically around 0.3 W/m2K compared to gas-filled glazing, which usually ranges from 1.0 to 1.4 W/m2K. This advanced thermal insulation translates to significant cost savings on heating and cooling bills over time, especially in extreme climates. Although vacuum glazing tends to have a higher upfront cost than gas-filled alternatives like argon or krypton-filled units, its long-term energy savings and durability make it a more economical choice for energy-conscious buildings.

Acoustic Insulation Capabilities

Vacuum insulating glazing exhibits superior acoustic insulation capabilities compared to gas-filled glazing due to the absence of gas molecules, significantly reducing sound transmission through the unit. The vacuum layer effectively minimizes sound vibration and external noise, achieving noise reduction levels of up to 50 dB. Gas-filled glazing, typically using argon or krypton, provides moderate soundproofing but cannot match the near-complete sound deadening properties of vacuum insulation.

Durability and Longevity

Vacuum insulating glazing offers superior durability due to the absence of gas that can leak or degrade over time, ensuring consistent thermal performance for decades. Gas-filled glazing, commonly filled with argon or krypton, may experience gas leakage that reduces its insulating efficiency and lifespan. Choosing vacuum insulating glazing enhances your window's longevity by maintaining optimal insulation without the risk of gas depletion.

Environmental Impact Analysis

Vacuum insulating glazing significantly reduces heat transfer by eliminating gas convection and conduction, resulting in lower energy consumption for heating and cooling compared to gas-filled glazing, which retains insulating gases like argon or krypton. The production of vacuum glazing materials typically involves fewer greenhouse gas emissions, as it avoids the use of gases that can eventually leak and contribute to global warming. Your choice of vacuum insulating glazing can enhance environmental sustainability by improving building energy efficiency and minimizing the carbon footprint associated with climate control.

Suitability for Residential and Commercial Buildings

Vacuum insulating glazing offers superior thermal insulation and slim profile advantages, making it highly suitable for both residential and commercial buildings seeking energy efficiency and space-saving window solutions. Gas-filled glazing, often using argon or krypton, provides cost-effective thermal performance and sound insulation, commonly preferred in residential construction and mid-rise commercial buildings. The choice depends on project-specific insulation requirements, budget constraints, and desired window thickness.

Choosing the Right Glazing Technology

Vacuum insulating glazing offers superior thermal insulation by eliminating air between panes, reducing heat transfer more effectively than gas-filled glazing, which relies on noble gases like argon or krypton to improve energy efficiency. When choosing the right glazing technology, consider factors such as climate, window frame compatibility, and budget constraints, as vacuum glazing typically provides higher insulation with a thinner profile but at a greater cost. For projects demanding enhanced thermal performance in compact spaces, vacuum insulating glazing is ideal, whereas gas-filled glazing suits applications prioritizing cost-effectiveness and ease of installation.

Vacuum insulating glazing vs gas-filled glazing Infographic

libmatt.com

libmatt.com