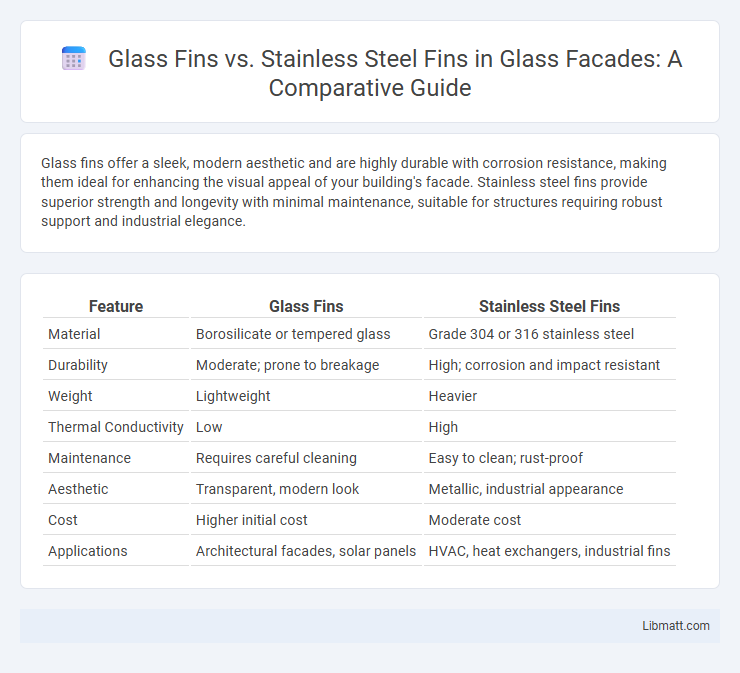

Glass fins offer a sleek, modern aesthetic and are highly durable with corrosion resistance, making them ideal for enhancing the visual appeal of your building's facade. Stainless steel fins provide superior strength and longevity with minimal maintenance, suitable for structures requiring robust support and industrial elegance.

Table of Comparison

| Feature | Glass Fins | Stainless Steel Fins |

|---|---|---|

| Material | Borosilicate or tempered glass | Grade 304 or 316 stainless steel |

| Durability | Moderate; prone to breakage | High; corrosion and impact resistant |

| Weight | Lightweight | Heavier |

| Thermal Conductivity | Low | High |

| Maintenance | Requires careful cleaning | Easy to clean; rust-proof |

| Aesthetic | Transparent, modern look | Metallic, industrial appearance |

| Cost | Higher initial cost | Moderate cost |

| Applications | Architectural facades, solar panels | HVAC, heat exchangers, industrial fins |

Introduction to Glass Fins and Stainless Steel Fins

Glass fins offer superior corrosion resistance and transparency, making them ideal for architectural applications requiring aesthetic appeal and durability. Stainless steel fins provide exceptional strength, thermal conductivity, and resistance to harsh environmental conditions, frequently used in industrial heat exchangers and HVAC systems. Both materials optimize heat transfer efficiency, with glass fins excelling in visibility and stainless steel fins in mechanical robustness.

Material Composition and Properties

Glass fins consist primarily of silica-based glass fibers combined with resin matrices, offering excellent thermal insulation, corrosion resistance, and a lightweight structure. Stainless steel fins are composed of high-grade alloys such as 304 or 316 stainless steel, providing superior durability, high tensile strength, and resistance to oxidation and mechanical damage under harsh environmental conditions. The choice between glass fins and stainless steel fins depends on the application's requirements for thermal performance, structural integrity, and exposure to corrosive elements.

Structural Performance Comparison

Glass fins exhibit high tensile strength and excellent rigidity, allowing for slender and aesthetically pleasing structural designs in architectural applications. Stainless steel fins offer superior durability and resistance to corrosion while maintaining robust load-bearing capacity in various environmental conditions. The choice between glass and stainless steel fins depends on specific project requirements, balancing transparency and visual lightness with long-term structural resilience.

Aesthetic and Design Flexibility

Glass fins offer superior aesthetic appeal with their sleek, transparent appearance, allowing natural light to flow and enhancing modern architectural designs. Stainless steel fins provide greater design flexibility due to their strength and ability to be shaped into complex forms, enabling dynamic and bold structural statements. Your choice depends on whether you prioritize a minimalist, elegant look or versatile, robust design possibilities.

Durability and Weather Resistance

Glass fins offer superior durability and weather resistance due to their high resistance to corrosion, UV damage, and temperature fluctuations, making them ideal for harsh environments. Stainless steel fins provide strong structural integrity and good corrosion resistance, but may require regular maintenance to prevent rust and degradation over time. Your choice depends on the specific environmental conditions and maintenance capacity to ensure longevity and optimal performance.

Installation Methods and Complexity

Glass fins typically require specialized glazing systems and precision anchoring techniques to ensure structural integrity and aesthetic appeal, often demanding skilled labor and longer installation times. Stainless steel fins offer more straightforward installation through mechanical fasteners or welding, providing flexibility and faster assembly on-site. Both materials necessitate consideration of weight, thermal expansion, and building codes, but stainless steel's durability often simplifies long-term maintenance.

Maintenance and Longevity

Glass fins require less frequent maintenance as they are highly resistant to corrosion and staining, making them ideal for environments exposed to moisture or chemicals. Stainless steel fins offer exceptional durability and strength but may need regular cleaning to prevent rust and maintain their appearance over time. Your choice between these materials should consider the balance between ease of maintenance and the expected lifespan in your specific application.

Cost Analysis and Budget Considerations

Glass fins typically have a higher upfront cost due to specialized manufacturing processes but offer long-term savings through durability and low maintenance requirements. Stainless steel fins present a more affordable initial investment but may incur additional expenses over time due to corrosion and maintenance needs. Budget considerations should weigh the total cost of ownership, factoring in installation, longevity, and upkeep for both materials.

Environmental Impact and Sustainability

Glass fins offer a more sustainable option due to their recyclability and lower carbon footprint during manufacturing compared to stainless steel fins. Stainless steel fins, while durable, require significant energy-intensive mining and processing that contribute to higher greenhouse gas emissions. Choosing glass fins supports reduced environmental impact by promoting the use of eco-friendly materials with lower embodied energy.

Applications and Project Suitability

Glass fins excel in architectural projects requiring sleek, modern aesthetics and high transparency, commonly used in facades, atriums, and curtain walls where light transmission and minimal visual obstruction are critical. Stainless steel fins offer superior durability and corrosion resistance, making them ideal for exterior applications exposed to harsh weather, industrial environments, and high-traffic commercial buildings. Choosing between glass and stainless steel fins depends on project-specific factors such as structural load requirements, environmental conditions, and desired visual impact.

Glass fins vs stainless steel fins Infographic

libmatt.com

libmatt.com