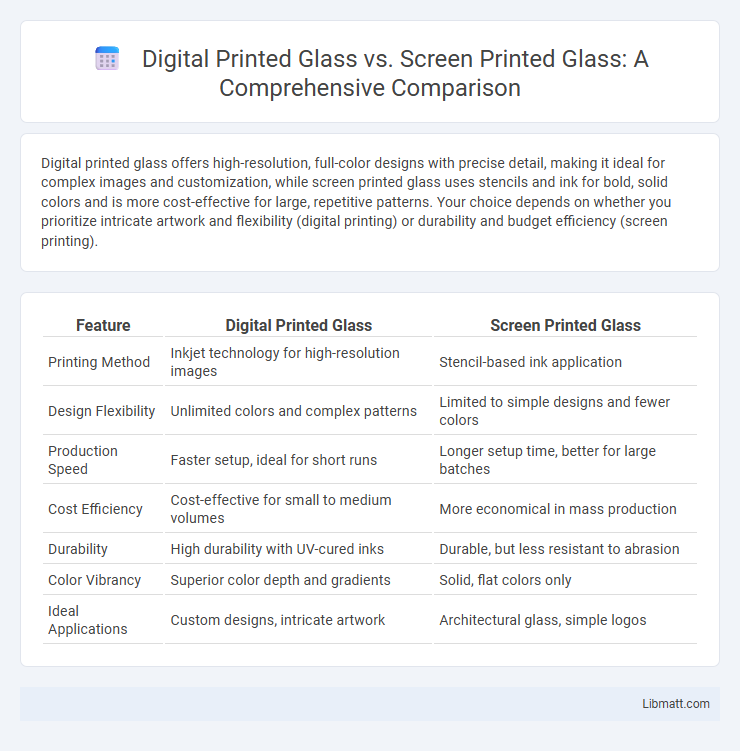

Digital printed glass offers high-resolution, full-color designs with precise detail, making it ideal for complex images and customization, while screen printed glass uses stencils and ink for bold, solid colors and is more cost-effective for large, repetitive patterns. Your choice depends on whether you prioritize intricate artwork and flexibility (digital printing) or durability and budget efficiency (screen printing).

Table of Comparison

| Feature | Digital Printed Glass | Screen Printed Glass |

|---|---|---|

| Printing Method | Inkjet technology for high-resolution images | Stencil-based ink application |

| Design Flexibility | Unlimited colors and complex patterns | Limited to simple designs and fewer colors |

| Production Speed | Faster setup, ideal for short runs | Longer setup time, better for large batches |

| Cost Efficiency | Cost-effective for small to medium volumes | More economical in mass production |

| Durability | High durability with UV-cured inks | Durable, but less resistant to abrasion |

| Color Vibrancy | Superior color depth and gradients | Solid, flat colors only |

| Ideal Applications | Custom designs, intricate artwork | Architectural glass, simple logos |

Overview of Digital Printed Glass and Screen Printed Glass

Digital printed glass utilizes advanced inkjet technology to apply high-resolution, full-color designs directly onto glass surfaces, allowing for intricate patterns and photographic-quality images with durable UV-cured inks. Screen printed glass involves pressing ink through a mesh stencil onto the glass, enabling precise application of single or limited colors, often used for bold, repetitive designs and functional coatings like frit patterns. Both methods enhance architectural aesthetics and functionality, but digital printing offers greater color variety and design complexity, while screen printing provides cost-effective, high-opacity results for large-scale production.

Key Differences in Printing Techniques

Digital printed glass uses high-resolution inkjet printers to apply detailed, full-color images directly onto the glass surface, allowing for greater design flexibility and gradient effects. Screen printed glass relies on mesh screens and stencils to apply layers of ceramic ink, producing more solid, opaque colors with excellent durability suited for repetitive patterns. Your choice depends on whether you prioritize intricate designs and color variety with digital printing or robust, consistent finishes offered by screen printing.

Image Quality and Design Flexibility

Digital printed glass offers superior image quality with high-resolution, photo-realistic prints and smooth color gradients, enabling intricate designs and vibrant visuals. Screen printed glass provides durable, consistent color application but is limited in design flexibility due to color layering and stencil constraints. Your choice depends on whether you prioritize detailed, customizable graphics or robust, uniform patterns for your project.

Color Reproduction and Range

Digital printed glass offers superior color reproduction with the ability to display intricate gradients and a wider color range, achieving photorealistic designs through precise inkjet technology. Screen printed glass, while effective for solid colors and repeat patterns, has a more limited palette and struggles with detailed color variations due to the use of stencils and thicker ink layers. The advanced ink formulations and pixel-by-pixel printing in digital methods provide enhanced vibrancy and tonal depth compared to the flat, uniform colors typical of screen printing.

Durability and Performance

Digital printed glass offers superior durability due to its advanced UV-cured inks that resist fading, scratching, and weathering better than traditional screen printed glass. Screen printed glass, while cost-effective for simple designs, tends to have lower performance in harsh environments because the ink layers are thicker and more prone to wear and delamination. When choosing between the two, your decision should factor in the intended application and exposure conditions to ensure optimal long-term performance.

Applications in Architecture and Interior Design

Digital printed glass offers high-resolution, full-color designs ideal for creating detailed artworks and custom patterns in modern architectural facades and interior partitions, enhancing aesthetic appeal with intricate visuals. Screen printed glass provides durable, uniform patterns and solid color blocks commonly used in shading, privacy screens, and decorative panels within office spaces and residential interiors. Your choice between digital and screen printed glass depends on the desired resolution, color complexity, and functional requirements of the architectural or interior design project.

Cost Comparison and Budget Considerations

Digital printed glass often presents higher initial costs due to advanced printing technology and detailed customization options, while screen printed glass remains more budget-friendly for large volume projects because of its simpler production process. Your choice depends on the scale and complexity of the design, as digital printing offers greater flexibility and precision for small batches, offsetting its higher price. Cost efficiency improves when matching the printing method with project requirements, ensuring optimal budget management.

Turnaround Time and Production Efficiency

Digital printed glass offers faster turnaround times due to direct printing technology, eliminating the need for stencil preparation and setup inherent in screen printed glass. This method enhances production efficiency by enabling on-demand, customizable prints with minimal downtime between runs. Your projects benefit from quicker delivery and the flexibility to produce complex designs without sacrificing quality or speed.

Environmental Impact and Sustainability

Digital printed glass uses less water and produces fewer chemical wastes than traditional screen printed glass, making it a more eco-friendly choice. It allows for precise ink application, reducing material waste and energy consumption during production. For your sustainable projects, choosing digital printed glass supports lower carbon emissions and promotes a greener building practice.

Choosing the Right Option for Your Project

When selecting between digital printed glass and screen printed glass, consider the complexity and color variety of your design; digital printing excels in detailed, multicolor images with high resolution, while screen printing suits simpler patterns with solid colors. Digital printing offers faster turnaround times and greater customization flexibility, ideal for projects requiring unique or small-batch prints. Your choice depends on the project's aesthetic requirements, budget, and production volume to ensure the best balance of quality and cost-efficiency.

Digital printed glass vs screen printed glass Infographic

libmatt.com

libmatt.com