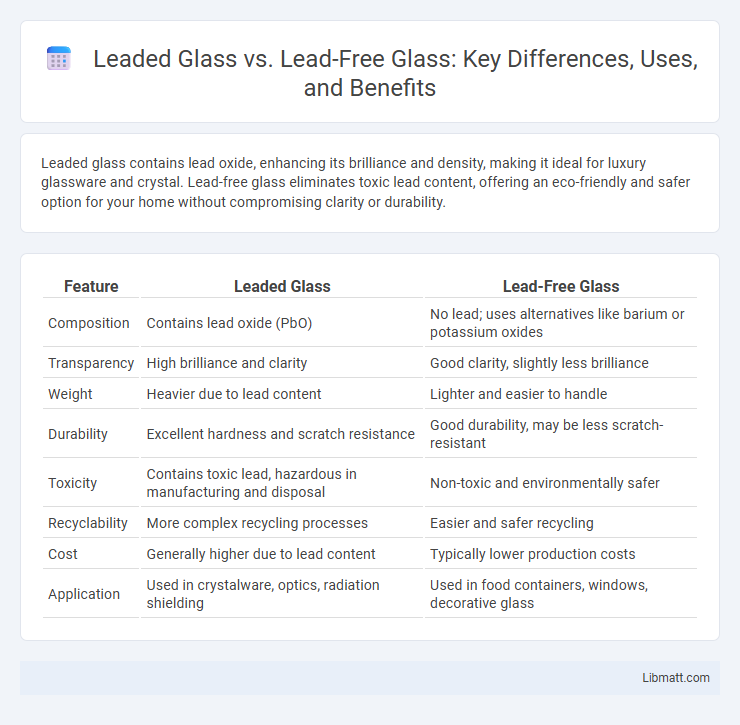

Leaded glass contains lead oxide, enhancing its brilliance and density, making it ideal for luxury glassware and crystal. Lead-free glass eliminates toxic lead content, offering an eco-friendly and safer option for your home without compromising clarity or durability.

Table of Comparison

| Feature | Leaded Glass | Lead-Free Glass |

|---|---|---|

| Composition | Contains lead oxide (PbO) | No lead; uses alternatives like barium or potassium oxides |

| Transparency | High brilliance and clarity | Good clarity, slightly less brilliance |

| Weight | Heavier due to lead content | Lighter and easier to handle |

| Durability | Excellent hardness and scratch resistance | Good durability, may be less scratch-resistant |

| Toxicity | Contains toxic lead, hazardous in manufacturing and disposal | Non-toxic and environmentally safer |

| Recyclability | More complex recycling processes | Easier and safer recycling |

| Cost | Generally higher due to lead content | Typically lower production costs |

| Application | Used in crystalware, optics, radiation shielding | Used in food containers, windows, decorative glass |

Introduction to Leaded Glass and Lead-Free Glass

Leaded glass contains lead oxide, enhancing its refractive index and brilliance, commonly used in decorative items and radiation shielding applications. Lead-free glass replaces lead oxide with alternative compounds like barium or zinc oxide to reduce toxicity while maintaining optical clarity and durability. Both types serve specific industry needs, balancing performance, safety, and environmental impact.

Historical Background and Development

Leaded glass, historically developed in the late 17th century by George Ravenscroft, revolutionized glassmaking with its high refractive index and brilliance, becoming a staple in fine crystal production. Lead-free glass emerged in the late 20th century due to environmental and health concerns, utilizing alternative additives like barium and zinc oxides to mimic the clarity and weight of traditional leaded glass. Your choice between leaded and lead-free glass reflects a balance between classic craftsmanship and modern sustainability standards.

Composition and Manufacturing Processes

Leaded glass contains lead oxide, typically 24% to 32% by weight, which increases its density and refractive index, while lead-free glass replaces lead oxide with alternatives like barium oxide, zinc oxide, or potassium oxide to maintain optical clarity and durability. The manufacturing process of leaded glass involves melting raw materials including silica, lead oxide, and soda ash at high temperatures to achieve its characteristic brilliance and weight. Lead-free glass, on the other hand, uses modified melting formulas and careful temperature control to produce a glass with similar optical properties but reduced environmental and health risks associated with lead.

Optical Properties and Clarity

Leaded glass offers superior optical properties with higher refractive index and brilliance, resulting in exceptional clarity and sparkle ideal for decorative and fine glassware. Lead-free glass, while environmentally friendly and safer, typically has a lower refractive index, which can lead to less light dispersion and reduced visual impact. Your choice between these materials depends on whether maximum brilliance or safety and sustainability is the priority in your application.

Radiation Shielding and Safety Applications

Leaded glass contains high amounts of lead oxide, providing superior radiation shielding properties essential in medical imaging, nuclear facilities, and radiation therapy rooms by effectively absorbing harmful X-rays and gamma rays. Lead-free glass, often produced using alternative heavy metals like barium or zinc, offers safer environmental and health profiles while maintaining comparable transparency and mechanical strength but generally exhibits slightly reduced attenuation of ionizing radiation. The choice between leaded and lead-free glass depends on balancing optimal radiation protection standards with regulatory requirements and concerns about toxicity and environmental impact in safety-critical applications.

Environmental Impact and Sustainability

Leaded glass contains toxic lead components that pose significant environmental hazards during manufacturing, disposal, and recycling due to lead leaching into soil and water. Lead-free glass offers a sustainable alternative by eliminating harmful lead, reducing environmental contamination and health risks while facilitating easier recycling processes. The shift towards lead-free glass supports eco-friendly manufacturing practices aligned with global environmental regulations and sustainability goals.

Health Concerns and Regulatory Compliance

Leaded glass contains toxic lead oxide, posing significant health risks such as lead poisoning and environmental contamination, prompting strict regulations in many countries. Lead-free glass, often made from safer alternatives like barium or zinc oxide, offers a non-toxic option that meets global safety standards and regulatory compliance. Your choice of glass should prioritize lead-free materials to ensure health safety and adherence to evolving environmental regulations.

Cost Comparison and Market Availability

Leaded glass typically incurs higher costs due to its lead content and specialized manufacturing processes, making it less affordable compared to lead-free glass, which utilizes alternative, cheaper materials. Market availability favors lead-free glass, as increasing environmental regulations and health concerns drive demand and production of lead-free options globally. When considering your purchase, lead-free glass offers a more cost-effective solution with broader accessibility in the market.

Common Uses and Industry Preferences

Leaded glass is often preferred in applications requiring high refractive indexes and superior clarity, such as in fine crystalware and decorative lighting fixtures. Lead-free glass is favored in the electronics and food packaging industries because it eliminates toxic lead exposure while maintaining strength and durability. Your choice between leaded and lead-free glass should consider the need for optical quality versus environmental and health safety standards in your specific industry.

Choosing the Right Glass Type: Key Considerations

When choosing between leaded glass and lead-free glass, consider the application's safety requirements, weight, and optical clarity. Leaded glass offers superior radiation shielding and enhanced brilliance but is heavier and contains toxic lead, necessitating careful handling and disposal. Your decision should balance performance needs with environmental and health considerations to ensure the optimal glass type for your specific project.

Leaded glass vs lead-free glass Infographic

libmatt.com

libmatt.com