Low-iron glass offers superior clarity and color accuracy compared to regular glass, making it ideal for applications where visual quality is crucial, such as in display cases and architectural features. Your choice of low-iron glass enhances the overall aesthetic by reducing the greenish tint commonly found in standard glass, ensuring a cleaner and brighter appearance.

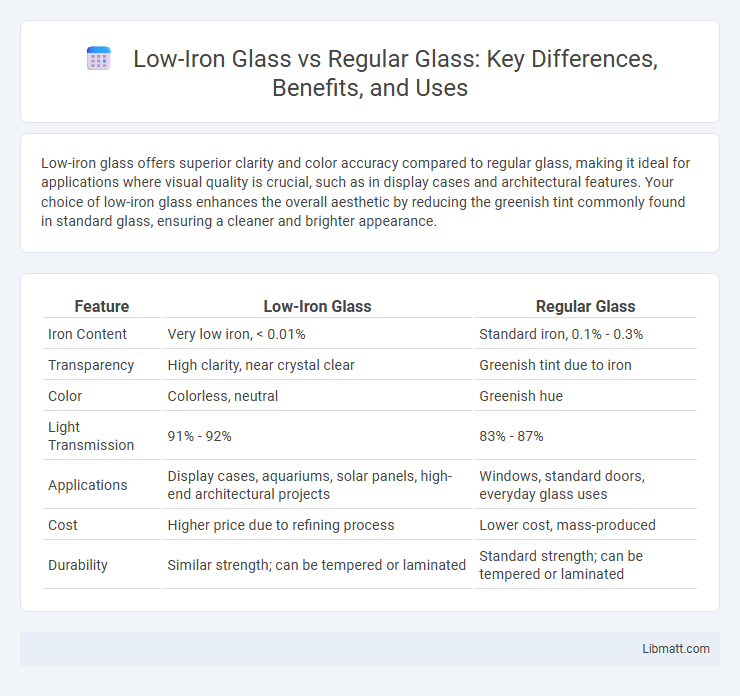

Table of Comparison

| Feature | Low-Iron Glass | Regular Glass |

|---|---|---|

| Iron Content | Very low iron, < 0.01% | Standard iron, 0.1% - 0.3% |

| Transparency | High clarity, near crystal clear | Greenish tint due to iron |

| Color | Colorless, neutral | Greenish hue |

| Light Transmission | 91% - 92% | 83% - 87% |

| Applications | Display cases, aquariums, solar panels, high-end architectural projects | Windows, standard doors, everyday glass uses |

| Cost | Higher price due to refining process | Lower cost, mass-produced |

| Durability | Similar strength; can be tempered or laminated | Standard strength; can be tempered or laminated |

Introduction to Low-Iron Glass and Regular Glass

Low-iron glass contains significantly reduced iron content, resulting in higher clarity and enhanced light transmission compared to regular glass, which has a noticeable green tint due to its iron oxide content. Regular glass is the standard option commonly used in windows and framing but lacks the purity and optical precision of low-iron glass. Choosing low-iron glass improves the visual quality of your projects by minimizing color distortion and maximizing transparency.

Composition Differences: What Sets Them Apart

Low-iron glass contains significantly less iron oxide compared to regular glass, resulting in higher clarity and enhanced light transmission. The reduced iron content minimizes the greenish tint typically found in standard glass, making low-iron glass ideal for applications requiring true color visibility and maximum transparency. Your choice between the two types depends on whether color fidelity and clarity are critical for your project.

Optical Clarity and Transparency Comparison

Low-iron glass offers significantly higher optical clarity and enhanced transparency compared to regular glass due to its reduced iron oxide content, which minimizes the greenish tint typically present in standard glass. This increased transparency allows for truer color representation and greater light transmission, making low-iron glass ideal for architectural applications requiring maximum visibility. Regular glass, containing higher iron levels, exhibits a noticeable green hue that can distort color perception and reduce clarity, especially in thicker panels.

Color and Visual Appearance

Low-iron glass exhibits significantly higher clarity and a more neutral, true-to-color appearance compared to regular glass, which often has a noticeable green tint due to iron content. This enhanced transparency in low-iron glass makes it ideal for applications requiring minimal color distortion and maximum light transmission. Consequently, low-iron glass is preferred in architectural and display settings where accurate color representation and aesthetic appeal are critical.

Applications and Common Uses

Low-iron glass is preferred in applications requiring superior clarity and true color representation, such as in high-end windows, display cases, solar panels, and aquariums. Regular glass, while more economical, is commonly used for standard windows, picture frames, and everyday glassware where slight greenish tint and lower clarity are acceptable. Your choice between low-iron and regular glass depends on the need for optical performance versus cost efficiency in common uses.

Strength and Durability Analysis

Low-iron glass exhibits enhanced strength and durability compared to regular glass due to its higher purity and reduced iron content, which minimizes weaknesses caused by iron oxide inclusions. This type of glass is less prone to discoloration and degradation when exposed to UV light and environmental stressors, contributing to longer lifespan in architectural and automotive applications. The structural integrity of low-iron glass supports better resistance to impact and pressure, making it suitable for high-performance requirements.

Cost Considerations: Low-Iron vs Regular Glass

Low-iron glass typically costs 20-40% more than regular glass due to its higher manufacturing purity and enhanced clarity, which reduces the greenish tint found in standard glass. This premium price can be justified in applications where aesthetics and light transmission are critical, such as in display cases, aquariums, or high-end architectural projects. Evaluating your budget against these benefits will help determine if the improved visual quality of low-iron glass aligns with your specific project needs.

Impact on Energy Efficiency and UV Transmission

Low-iron glass offers superior energy efficiency compared to regular glass by allowing higher solar heat gain and maximizing natural daylight, which reduces reliance on artificial lighting and heating. It transmits up to 90% of visible light with minimal green tint, enhancing transparency and aesthetic appeal in architectural applications. Additionally, low-iron glass significantly reduces ultraviolet (UV) transmission, protecting interiors from UV-induced fading and deterioration.

Design Flexibility and Aesthetics

Low-iron glass offers superior clarity and color accuracy compared to regular glass, enhancing design flexibility by allowing architects and designers to create visually striking spaces with true-to-life colors and minimal greenish tint. Its increased light transmission improves natural illumination, making it ideal for applications where aesthetics and transparency are paramount, such as in facades, display cases, and interior partitions. Using low-iron glass, you can achieve modern, sleek designs that elevate the overall visual appeal without compromising structural integrity.

Choosing the Right Glass: Factors to Consider

Low-iron glass offers enhanced clarity and true color representation due to its reduced iron content compared to regular glass, making it ideal for applications requiring maximal light transmission and minimal green tint. Consider factors such as the intended use, aesthetic preferences, budget constraints, and energy efficiency requirements when choosing between low-iron and regular glass. In architectural and display settings where visibility and color accuracy are crucial, low-iron glass provides superior performance despite a higher cost.

Low-iron glass vs regular glass Infographic

libmatt.com

libmatt.com