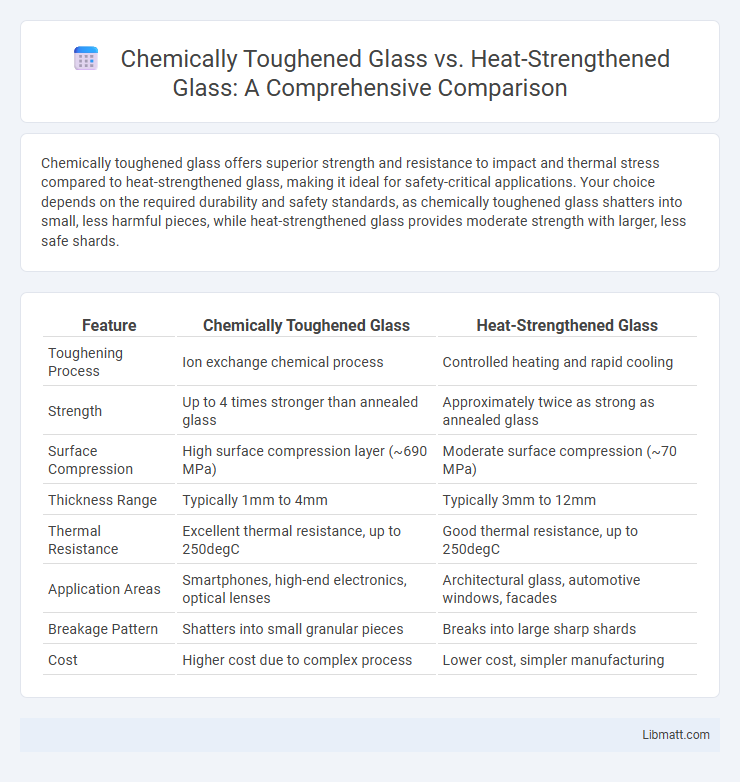

Chemically toughened glass offers superior strength and resistance to impact and thermal stress compared to heat-strengthened glass, making it ideal for safety-critical applications. Your choice depends on the required durability and safety standards, as chemically toughened glass shatters into small, less harmful pieces, while heat-strengthened glass provides moderate strength with larger, less safe shards.

Table of Comparison

| Feature | Chemically Toughened Glass | Heat-Strengthened Glass |

|---|---|---|

| Toughening Process | Ion exchange chemical process | Controlled heating and rapid cooling |

| Strength | Up to 4 times stronger than annealed glass | Approximately twice as strong as annealed glass |

| Surface Compression | High surface compression layer (~690 MPa) | Moderate surface compression (~70 MPa) |

| Thickness Range | Typically 1mm to 4mm | Typically 3mm to 12mm |

| Thermal Resistance | Excellent thermal resistance, up to 250degC | Good thermal resistance, up to 250degC |

| Application Areas | Smartphones, high-end electronics, optical lenses | Architectural glass, automotive windows, facades |

| Breakage Pattern | Shatters into small granular pieces | Breaks into large sharp shards |

| Cost | Higher cost due to complex process | Lower cost, simpler manufacturing |

Introduction to Chemically Toughened and Heat-Strengthened Glass

Chemically toughened glass undergoes an ion-exchange process that replaces smaller ions in the glass surface with larger ones, creating high compressive stress and enhancing strength up to four times that of untreated glass. Heat-strengthened glass is produced by controlled thermal tempering with slower cooling than fully tempered glass, resulting in strength twice that of annealed glass and improved resistance to thermal stress. Both types offer improved durability and safety but differ in manufacturing methods, mechanical properties, and typical applications.

Manufacturing Processes: Chemical vs. Heat Strengthening

Chemically toughened glass undergoes an ion-exchange process where smaller sodium ions in the glass surface are replaced by larger potassium ions from a molten salt bath, creating a compressive stress layer. Heat-strengthened glass is produced by heating the glass to just below its melting point and then rapidly cooling it with air, inducing surface compression and internal tension. Understanding these distinct manufacturing processes helps you select the optimal glass type based on performance and durability requirements.

Key Differences in Glass Strength and Durability

Chemically toughened glass exhibits enhanced strength through ion exchange, replacing smaller sodium ions with larger potassium ions, resulting in surface compression up to 10 times greater than heat-strengthened glass. Heat-strengthened glass undergoes thermal treatment by heating to approximately 650degC and rapid cooling, offering strength twice that of annealed glass but less than chemically toughened variants. Chemically toughened glass demonstrates superior durability against impacts and thermal stresses, making it ideal for demanding safety applications, whereas heat-strengthened glass provides moderate strength enhancement for less critical structural use.

Surface Compression Comparison

Chemically toughened glass exhibits a higher surface compression layer, typically around 690 MPa, compared to heat-strengthened glass, which ranges from 100 to 300 MPa. This increased surface compression in chemically toughened glass significantly enhances its resistance to impact and thermal stress. The deeper compression layer in chemically toughened glass, often up to 40 microns, contrasts with the shallower layer in heat-strengthened glass, generally less than 10 microns, resulting in superior durability and safety performance.

Resistance to Thermal and Mechanical Stress

Chemically toughened glass offers superior resistance to thermal and mechanical stress due to its ion-exchange strengthening process, which creates a deep compressive layer on the surface, enhancing durability and reducing the risk of breakage under extreme temperature variations. Heat-strengthened glass, while stronger than annealed glass and capable of withstanding moderate thermal and mechanical stress, has a lower surface compression and is more prone to breakage under sudden thermal shock compared to chemically toughened glass. You should choose chemically toughened glass when maximum resistance to thermal and mechanical stress is crucial for your application.

Applications of Chemically Toughened Glass

Chemically toughened glass is widely used in applications requiring superior strength and high scratch resistance, such as smartphone screens, architectural facades, and automotive windows. This glass undergoes an ion-exchange process that enhances its durability, making it ideal for touchscreens, eyewear lenses, and high-performance solar panels. Your projects can benefit from chemically toughened glass when impact resistance and optical clarity are critical.

Applications of Heat-Strengthened Glass

Heat-strengthened glass is commonly used in architectural applications where enhanced strength and thermal resistance are required, such as building facades, skylights, and curtain walls. It offers approximately twice the strength of annealed glass, making it ideal for locations prone to moderate impact or thermal stress. Your project can benefit from heat-strengthened glass in areas that demand safety and durability without the need for the higher impact resistance of fully tempered glass.

Safety Considerations and Breakage Patterns

Chemically toughened glass offers enhanced safety due to its high tensile surface stress, causing it to break into small, blunt fragments that reduce injury risk. Heat-strengthened glass, with moderate internal stress, fractures into larger, more jagged shards, posing a greater hazard upon breakage. Choosing chemically toughened glass improves safety in applications requiring strict impact resistance and minimal injury potential.

Cost and Availability Analysis

Chemically toughened glass typically costs more than heat-strengthened glass due to its complex ion-exchange manufacturing process, making it less widely available in standard markets. Heat-strengthened glass offers a cost-effective alternative with faster production times and broader availability, often found through local suppliers. Your choice depends on balancing higher expense and limited supply of chemically toughened glass against the affordability and accessibility of heat-strengthened options.

Choosing the Right Glass for Your Project

Chemically toughened glass offers higher strength and better edge stability compared to heat-strengthened glass, making it ideal for applications requiring enhanced safety and durability. Heat-strengthened glass is more cost-effective and provides moderate strength, suitable for projects with less stringent performance demands. Your project's specific structural requirements and budget will guide the optimal choice between chemically toughened and heat-strengthened glass.

Chemically toughened glass vs heat-strengthened glass Infographic

libmatt.com

libmatt.com