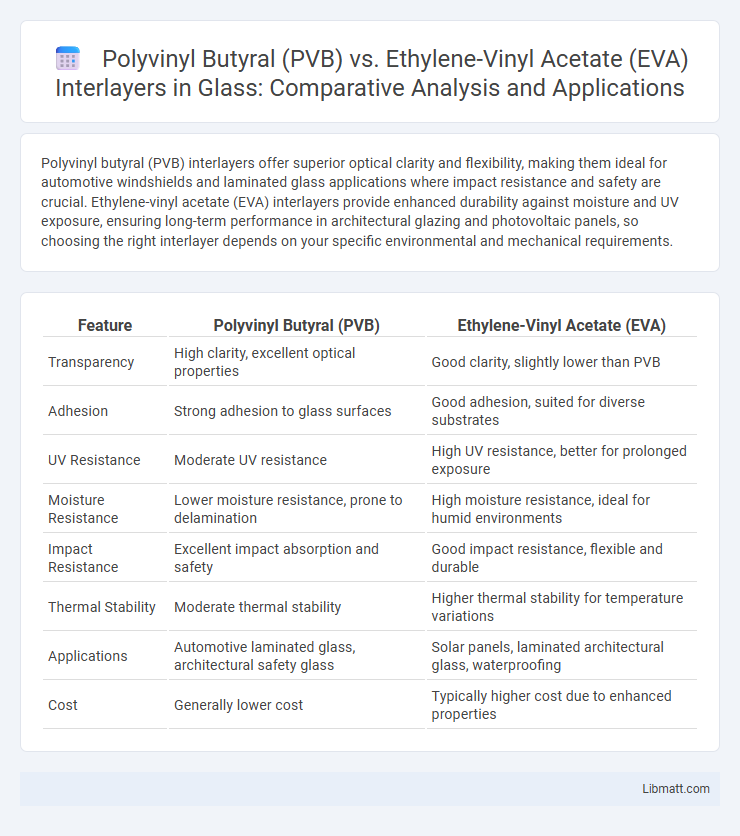

Polyvinyl butyral (PVB) interlayers offer superior optical clarity and flexibility, making them ideal for automotive windshields and laminated glass applications where impact resistance and safety are crucial. Ethylene-vinyl acetate (EVA) interlayers provide enhanced durability against moisture and UV exposure, ensuring long-term performance in architectural glazing and photovoltaic panels, so choosing the right interlayer depends on your specific environmental and mechanical requirements.

Table of Comparison

| Feature | Polyvinyl Butyral (PVB) | Ethylene-Vinyl Acetate (EVA) |

|---|---|---|

| Transparency | High clarity, excellent optical properties | Good clarity, slightly lower than PVB |

| Adhesion | Strong adhesion to glass surfaces | Good adhesion, suited for diverse substrates |

| UV Resistance | Moderate UV resistance | High UV resistance, better for prolonged exposure |

| Moisture Resistance | Lower moisture resistance, prone to delamination | High moisture resistance, ideal for humid environments |

| Impact Resistance | Excellent impact absorption and safety | Good impact resistance, flexible and durable |

| Thermal Stability | Moderate thermal stability | Higher thermal stability for temperature variations |

| Applications | Automotive laminated glass, architectural safety glass | Solar panels, laminated architectural glass, waterproofing |

| Cost | Generally lower cost | Typically higher cost due to enhanced properties |

Introduction to Polyvinyl Butyral (PVB) and Ethylene-Vinyl Acetate (EVA) Interlayers

Polyvinyl Butyral (PVB) interlayers are widely used in laminated glass due to their excellent adhesion, optical clarity, and impact resistance, providing enhanced safety and durability in automotive and architectural applications. Ethylene-Vinyl Acetate (EVA) interlayers offer superior UV resistance, moisture durability, and flexibility, making them ideal for photovoltaic panels and specialty laminated glass products. Both PVB and EVA interlayers contribute to improved laminated glass performance, but their distinct chemical properties and environmental resilience determine their specific suitability across various industries.

Chemical Composition and Physical Properties

Polyvinyl butyral (PVB) interlayers consist of polyvinyl alcohol modified with butyraldehyde, providing excellent adhesion, flexibility, and optical clarity. Ethylene-vinyl acetate (EVA) interlayers are copolymers of ethylene and vinyl acetate, known for their toughness, moisture resistance, and good bonding in laminated glass applications. Your selection between PVB and EVA depends on specific requirements for impact resistance, UV stability, and environmental conditions.

Manufacturing Processes: PVB vs EVA

Polyvinyl butyral (PVB) interlayers undergo a complex manufacturing process involving alcoholysis of polyvinyl acetate followed by blending with plasticizers to achieve high adhesion and optical clarity. Ethylene-vinyl acetate (EVA) interlayers are produced through polymerization of ethylene and vinyl acetate monomers, followed by compounding and lamination, resulting in flexible and durable films with enhanced moisture resistance. PVB manufacturing emphasizes meticulous purification and plasticizer integration, whereas EVA production focuses on polymer blending and crosslinking to optimize impact resistance and UV stability.

Optical Clarity and Light Transmission

Polyvinyl butyral (PVB) interlayers offer superior optical clarity with minimal haze, ensuring high light transmission rates typically above 85%, making them ideal for automotive and architectural laminated glass. Ethylene-vinyl acetate (EVA) interlayers, while providing good clarity, often exhibit slightly lower light transmittance due to their tendency to yellow over time under UV exposure. Advanced PVB formulations maintain consistent transparency and resist UV-induced degradation, outperforming EVA in applications demanding prolonged optical performance.

Adhesion and Bonding Capabilities

Polyvinyl butyral (PVB) interlayers exhibit superior adhesion and bonding capabilities to glass surfaces due to their strong polar functional groups, enhancing laminate durability and impact resistance. Ethylene-vinyl acetate (EVA) offers good adhesion but generally underperforms compared to PVB in long-term bonding strength and moisture resistance. Your choice between PVB and EVA should consider the specific application requirements, especially where maximum interlayer-to-glass adhesion is critical.

Durability: Moisture, UV, and Temperature Resistance

Polyvinyl butyral (PVB) interlayers exhibit moderate moisture resistance but tend to degrade under prolonged UV exposure, leading to reduced durability in harsh outdoor conditions. Ethylene-vinyl acetate (EVA) interlayers offer superior moisture and UV resistance, maintaining better optical clarity and adhesion over time, especially in laminated glass applications subjected to variable temperatures. EVA's thermal stability enhances its performance in environments with fluctuating temperatures, making it more resilient compared to PVB for long-term durability.

Safety and Performance in Laminated Glass

Polyvinyl butyral (PVB) interlayers offer superior adhesion and clarity, enhancing impact resistance and preventing glass shards from causing injury, which ensures high safety in laminated glass applications. Ethylene-vinyl acetate (EVA) interlayers provide excellent UV resistance and better moisture durability, making them ideal for outdoor environments with prolonged sun exposure. Your choice between PVB and EVA affects the balance between safety performance and environmental resilience in laminated glass.

Applications: Architectural, Automotive, and Photovoltaic Uses

Polyvinyl butyral (PVB) interlayers are widely used in automotive windshields and architectural laminated glass due to their excellent adhesion, clarity, and impact resistance, ensuring enhanced safety and durability. Ethylene-vinyl acetate (EVA) interlayers dominate in photovoltaic module encapsulation, providing superior moisture resistance, flexibility, and long-term weatherability essential for solar panel longevity. Your choice between PVB and EVA interlayers depends on the specific application requirements, balancing factors like mechanical strength, optical clarity, and environmental exposure.

Cost Comparison and Market Availability

Polyvinyl butyral (PVB) interlayers generally have a higher cost than ethylene-vinyl acetate (EVA) due to their advanced adhesion properties and superior optical clarity, making them the preferred choice in automotive and architectural applications. EVA interlayers offer a more budget-friendly alternative, widely used in photovoltaic modules and laminated safety glass where cost efficiency is critical. Market availability favors PVB with extensive global production capacity and well-established supply chains, whereas EVA, though widely available, is more commonly sourced from specialized manufacturers focused on solar and packaging industries.

Choosing the Right Interlayer: Key Considerations

Polyvinyl butyral (PVB) offers superior clarity, adhesion, and impact resistance, making it ideal for laminated safety glass, whereas ethylene-vinyl acetate (EVA) provides better moisture resistance and durability in harsh environments. Your choice should consider factors such as UV resistance, acoustic insulation requirements, and the specific application's exposure to weather conditions. Selecting the right interlayer ensures optimal performance, safety, and longevity for laminated glass products.

Polyvinyl butyral (PVB) vs ethylene-vinyl acetate (EVA) interlayers Infographic

libmatt.com

libmatt.com