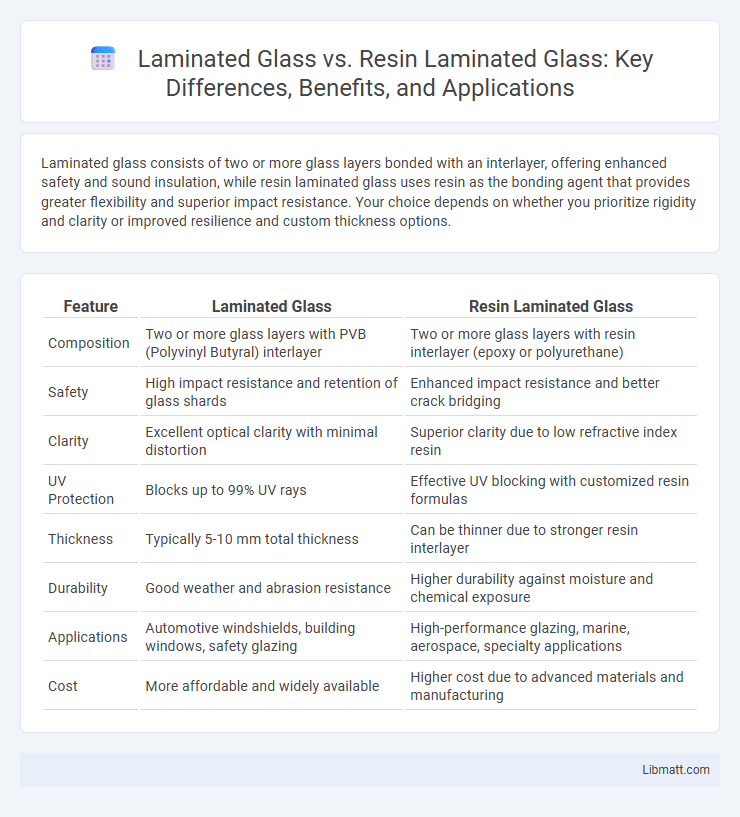

Laminated glass consists of two or more glass layers bonded with an interlayer, offering enhanced safety and sound insulation, while resin laminated glass uses resin as the bonding agent that provides greater flexibility and superior impact resistance. Your choice depends on whether you prioritize rigidity and clarity or improved resilience and custom thickness options.

Table of Comparison

| Feature | Laminated Glass | Resin Laminated Glass |

|---|---|---|

| Composition | Two or more glass layers with PVB (Polyvinyl Butyral) interlayer | Two or more glass layers with resin interlayer (epoxy or polyurethane) |

| Safety | High impact resistance and retention of glass shards | Enhanced impact resistance and better crack bridging |

| Clarity | Excellent optical clarity with minimal distortion | Superior clarity due to low refractive index resin |

| UV Protection | Blocks up to 99% UV rays | Effective UV blocking with customized resin formulas |

| Thickness | Typically 5-10 mm total thickness | Can be thinner due to stronger resin interlayer |

| Durability | Good weather and abrasion resistance | Higher durability against moisture and chemical exposure |

| Applications | Automotive windshields, building windows, safety glazing | High-performance glazing, marine, aerospace, specialty applications |

| Cost | More affordable and widely available | Higher cost due to advanced materials and manufacturing |

Introduction to Laminated Glass and Resin Laminated Glass

Laminated glass consists of two or more layers of glass bonded together with an interlayer, typically polyvinyl butyral (PVB), providing enhanced safety and sound insulation. Resin laminated glass replaces the traditional PVB interlayer with a resin material, offering superior clarity, improved impact resistance, and the ability to incorporate larger glass sizes without distortion. Both types are widely used in automotive, architectural, and security applications, but resin laminated glass is preferred for high-performance requirements due to its durability and optical advantages.

Composition and Manufacturing Processes

Laminated glass consists of two or more glass layers bonded with an interlayer, typically polyvinyl butyral (PVB), through heat and pressure to enhance safety and durability. Resin laminated glass replaces the traditional PVB interlayer with a resin material, which is injected and cured between the glass layers, offering improved clarity and resistance to moisture. The manufacturing process of resin laminated glass involves precise resin infusion and UV curing techniques, whereas standard laminated glass relies on autoclaving to achieve adhesion.

Key Differences Between Laminated Glass Types

Laminated glass consists of two or more glass layers bonded with an interlayer, typically polyvinyl butyral (PVB), offering impact resistance and safety by holding shards together upon breakage. Resin laminated glass uses a clear resin interlayer, such as epoxy or polyurethane, providing enhanced structural integrity, optical clarity, and customization options for thickness and impact resistance. Your choice depends on specific application needs, where resin laminated glass excels in durability and transparency, while traditional laminated glass is preferred for cost-effective safety glazing.

Strength and Impact Resistance Comparison

Laminated glass consists of two or more glass layers bonded with a polyvinyl butyral (PVB) interlayer, offering high strength and impact resistance by preventing shattering upon impact. Resin laminated glass replaces the traditional PVB with a resin interlayer, providing enhanced impact resistance, greater flexibility, and improved performance against dynamic loads and ballistic impacts. Your choice between these materials depends on the specific strength requirements and the level of safety needed for your application.

Acoustic and Thermal Insulation Performance

Laminated glass provides effective acoustic insulation by using a polyvinyl butyral (PVB) interlayer that dampens sound vibrations but may have limited thermal insulation properties depending on the glass thickness and composition. Resin laminated glass, however, incorporates a resin interlayer that enhances both acoustic and thermal insulation performance due to its superior energy-absorbing characteristics and improved resistance to heat transfer. This makes resin laminated glass a more efficient choice for environments requiring higher soundproofing and thermal management, such as in commercial buildings and premium residential applications.

Safety and Security Features

Laminated glass consists of two or more glass layers bonded with an interlayer, providing enhanced shatter resistance and preventing dangerous shards from causing injury. Resin laminated glass uses a resin interlayer, offering superior impact resistance and improved energy absorption, making it ideal for high-security applications. Your choice between the two affects the level of protection against forced entry, impact hazards, and safety in case of breakage.

Durability and Longevity Assessment

Laminated glass consists of two or more glass layers bonded with an interlayer, offering high impact resistance and durability suitable for architectural and automotive applications. Resin laminated glass incorporates a resin interlayer, enhancing flexibility and improved resistance to delamination, especially in large or curved installations. The resin interlayer's superior adhesion properties contribute to increased longevity by preventing moisture ingress and maintaining structural integrity under varying environmental conditions.

Design Flexibility and Applications

Laminated glass offers excellent design flexibility by incorporating various interlayers like PVB or SGP, allowing customization in color, opacity, and acoustic performance for architectural and automotive applications. Resin laminated glass enhances this flexibility by using clear or colored resin interlayers that enable intricate shapes and embedded materials, ideal for innovative facades, decorative installations, and safety glazing in high-impact environments. Your choice between these options depends on the specific design requirements and performance criteria of your project.

Cost and Installation Considerations

Laminated glass generally offers a lower upfront cost compared to resin laminated glass, making it a budget-friendly choice for large-scale projects or standard safety applications. Installation of traditional laminated glass is typically quicker and more straightforward due to established industry practices and the rigid interlayer, which simplifies handling and fitting. Resin laminated glass, although more expensive, requires specialized installation techniques to ensure the resin properly cures and bonds, particularly in applications demanding enhanced clarity and impact resistance.

Choosing the Right Option for Your Project

Laminated glass consists of two or more glass layers bonded with a plastic interlayer, offering enhanced safety and sound insulation, ideal for architectural and automotive applications. Resin laminated glass uses a transparent resin as the interlayer, providing superior clarity, flexibility, and impact resistance, suitable for custom designs and structural glazing. Selecting between laminated glass and resin laminated glass depends on your project's requirements for durability, aesthetic appeal, and performance under stress.

Laminated glass vs resin laminated glass Infographic

libmatt.com

libmatt.com