Vacuum glazing offers superior thermal insulation by creating a vacuum layer that minimizes heat transfer, making it thinner and lighter than traditional triple glazing. Your energy efficiency improves with vacuum glazing, especially in confined spaces where triple glazing's thicker profile may not be practical.

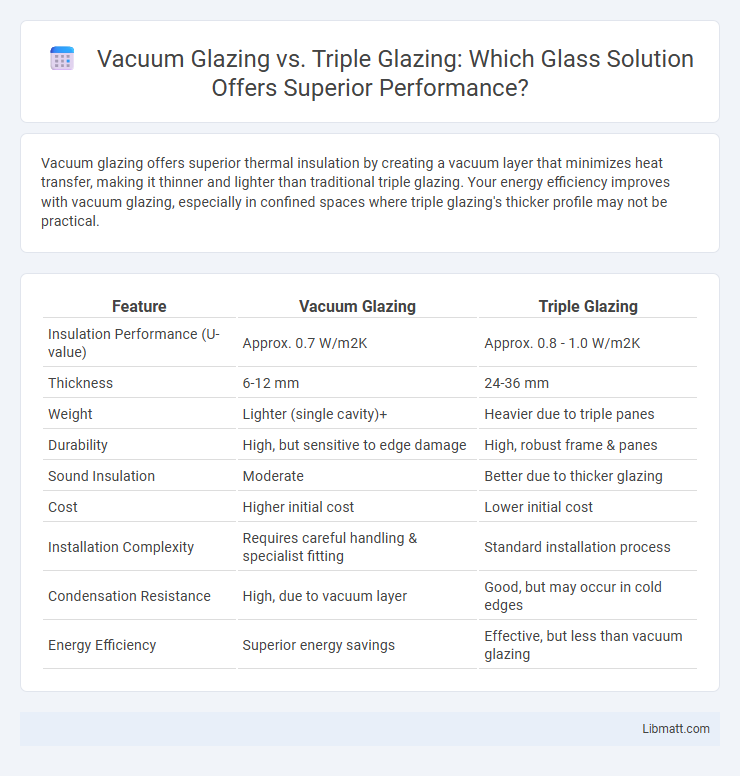

Table of Comparison

| Feature | Vacuum Glazing | Triple Glazing |

|---|---|---|

| Insulation Performance (U-value) | Approx. 0.7 W/m2K | Approx. 0.8 - 1.0 W/m2K |

| Thickness | 6-12 mm | 24-36 mm |

| Weight | Lighter (single cavity)+ | Heavier due to triple panes |

| Durability | High, but sensitive to edge damage | High, robust frame & panes |

| Sound Insulation | Moderate | Better due to thicker glazing |

| Cost | Higher initial cost | Lower initial cost |

| Installation Complexity | Requires careful handling & specialist fitting | Standard installation process |

| Condensation Resistance | High, due to vacuum layer | Good, but may occur in cold edges |

| Energy Efficiency | Superior energy savings | Effective, but less than vacuum glazing |

Introduction to Vacuum Glazing vs Triple Glazing

Vacuum glazing consists of two glass panes separated by a vacuum space that minimizes heat transfer, offering superior thermal insulation compared to traditional triple glazing. Triple glazing uses three glass panes with air or gas-filled spaces to reduce heat loss and improve energy efficiency in buildings. Your choice between vacuum and triple glazing depends on factors like insulation performance, thickness requirements, and budget.

How Vacuum Glazing Works

Vacuum glazing consists of two panes of glass separated by a thin vacuum layer that eliminates heat transfer through conduction and convection, significantly improving thermal insulation. Unlike triple glazing, which uses three glass panes with air or gas-filled spaces, vacuum glazing relies on maintaining a vacuum to minimize heat loss while keeping the window slim and lightweight. Your choice of glazing affects energy efficiency, with vacuum glazing offering superior insulation in tight spaces.

Understanding Triple Glazing Technology

Triple glazing technology uses three panes of glass separated by insulating gas-filled spaces to enhance thermal insulation and reduce heat loss. This arrangement significantly improves energy efficiency compared to double glazing by minimizing conductive and convective heat transfer. Vacuum glazing, meanwhile, replaces the gas-filled spaces with a near-vacuum to virtually eliminate heat conduction, offering superior insulation but at a higher cost and complexity.

Thermal Performance Comparison

Vacuum glazing offers superior thermal performance compared to triple glazing due to its extremely low heat transfer rate, achieved by a vacuum layer that minimizes conduction and convection. Triple glazing relies on multiple glass panes separated by inert gas fills like argon or krypton, which improves insulation but cannot match the near-complete heat barrier created by vacuum glazing. If maximizing energy efficiency and reducing heat loss is your priority, vacuum glazing provides a more effective thermal barrier, resulting in lower energy bills and enhanced indoor comfort.

Energy Efficiency and Insulation

Vacuum glazing offers superior thermal insulation by creating a near-perfect vacuum between glass panes, significantly reducing heat transfer compared to triple glazing's gas-filled spaces. You can expect vacuum glazing to enhance energy efficiency in buildings by minimizing heat loss and lowering heating and cooling costs. Its thin profile also allows for better insulation performance without the bulk of multiple glass layers found in triple glazing systems.

Soundproofing Capabilities

Vacuum glazing offers superior soundproofing capabilities due to its narrow gap filled with a vacuum, which effectively eliminates air-borne noise transmission. Triple glazing, with three layers of glass separated by air or gas-filled spaces, provides enhanced noise reduction but may not match the vacuum glazing's ability to block low-frequency sounds. Soundproofing performance depends on factors like glass thickness, spacer design, and sealing quality in both vacuum and triple glazing systems.

Thickness and Weight Differences

Vacuum glazing typically measures around 6mm in thickness, making it significantly thinner than triple glazing, which can range from 24mm to 36mm depending on the spacer width and glass layers. The weight of vacuum glazing is also considerably less, often about half that of triple glazing, due to its thinner glass panes and the absence of multiple gas-filled cavities. These differences make vacuum glazing a suitable option for applications requiring slim profiles and reduced structural load without sacrificing thermal insulation.

Cost Analysis and Investment Value

Vacuum glazing generally has a higher upfront cost compared to triple glazing due to advanced manufacturing techniques and materials, but it delivers superior thermal performance that can significantly reduce energy bills over time. Triple glazing offers a more affordable initial investment and improved insulation compared to double glazing, making it a popular choice for budget-conscious homeowners seeking energy efficiency. Your choice between vacuum and triple glazing should consider long-term savings and potential increases in property value, as higher-performing windows can enhance comfort and reduce heating and cooling expenses.

Durability and Lifespan

Vacuum glazing offers exceptional durability due to its sealed vacuum space, preventing moisture ingress and minimizing thermal expansion issues, which significantly extends its lifespan compared to traditional triple glazing. Triple glazing, while robust, is more susceptible to seal failures and condensation over time, potentially reducing its effective longevity. Manufacturers typically rate vacuum glazing systems to last over 50 years, whereas triple-glazed units often have warranties between 20 to 30 years, reflecting their differing durability and lifespan profiles.

Choosing the Right Glazing for Your Needs

Vacuum glazing offers superior thermal insulation by creating a near-vacuum space between glass panes, significantly reducing heat transfer compared to traditional triple glazing. Triple glazing, with its three layers of glass and gas fills like argon or krypton, provides excellent soundproofing and durability, making it ideal for harsh climates. Selecting between vacuum and triple glazing depends on priorities such as maximum energy efficiency, noise reduction, or budget constraints, ensuring the best fit for your building's performance requirements.

vacuum glazing vs triple glazing Infographic

libmatt.com

libmatt.com