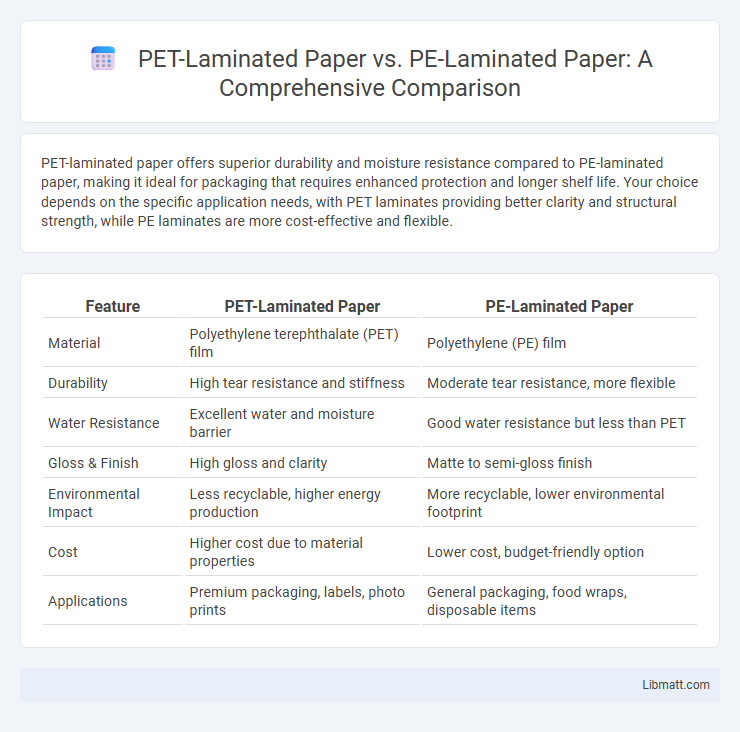

PET-laminated paper offers superior durability and moisture resistance compared to PE-laminated paper, making it ideal for packaging that requires enhanced protection and longer shelf life. Your choice depends on the specific application needs, with PET laminates providing better clarity and structural strength, while PE laminates are more cost-effective and flexible.

Table of Comparison

| Feature | PET-Laminated Paper | PE-Laminated Paper |

|---|---|---|

| Material | Polyethylene terephthalate (PET) film | Polyethylene (PE) film |

| Durability | High tear resistance and stiffness | Moderate tear resistance, more flexible |

| Water Resistance | Excellent water and moisture barrier | Good water resistance but less than PET |

| Gloss & Finish | High gloss and clarity | Matte to semi-gloss finish |

| Environmental Impact | Less recyclable, higher energy production | More recyclable, lower environmental footprint |

| Cost | Higher cost due to material properties | Lower cost, budget-friendly option |

| Applications | Premium packaging, labels, photo prints | General packaging, food wraps, disposable items |

Introduction to Laminated Paper Materials

PET-laminated paper offers superior durability, moisture resistance, and clarity compared to PE-laminated paper, making it ideal for premium packaging and labels requiring enhanced protection and print quality. PE-laminated paper, while more cost-effective and flexible, provides adequate moisture barrier and wrinkle resistance, suitable for general packaging applications. Your choice depends on the specific performance needs, balancing budget with desired strength and visual appeal.

Understanding PET-Laminated Paper

PET-laminated paper consists of a layer of polyethylene terephthalate (PET) film bonded to paper, enhancing durability, moisture resistance, and print quality compared to non-laminated paper. It offers superior tensile strength, chemical resistance, and temperature stability, making it ideal for high-end packaging, labels, and outdoor applications. PET-laminated paper improves product lifespan and aesthetic appeal by combining the rigidity of paper with the protective benefits of PET polymer.

Key Features of PE-Laminated Paper

PE-laminated paper features excellent moisture resistance, flexibility, and cost-effectiveness, making it ideal for packaging applications such as food wrappers and grocery bags. Its polyethylene coating provides a strong water barrier while maintaining recyclability compared to PET-laminated paper. The lightweight and durable nature of PE-laminated paper ensures efficient handling and protection of products during storage and transport.

Comparative Barrier Properties

PET-laminated paper exhibits superior barrier properties compared to PE-laminated paper, providing enhanced resistance to moisture, oxygen, and grease penetration. The polyethylene terephthalate layer offers a denser molecular structure, resulting in lower permeability and improved protection for sensitive products. PE-laminated paper is more cost-effective but generally offers lower barrier performance, making it suitable for applications with less stringent moisture and oxygen control requirements.

Printability and Aesthetics

PET-laminated paper offers superior printability with high gloss and vibrant color reproduction, ensuring sharp and clear images, while PE-laminated paper tends to have a matte or semi-gloss finish with less color vibrancy. The smooth surface of PET lamination enhances the aesthetics by providing a sleek, premium look and stronger durability against scratches. Your choice depends on whether you prioritize high-quality visual appeal and print detail (PET) or cost-effectiveness with decent finish (PE).

Environmental Impact and Recyclability

PET-laminated paper offers superior recyclability compared to PE-laminated paper due to its compatibility with existing recycling streams and reduced contamination risks. Environmental impact assessments reveal that PET lamination involves higher energy consumption during production but results in lower greenhouse gas emissions over the product lifecycle. In contrast, PE-laminated paper, while generally less energy-intensive to produce, poses greater challenges for recycling and often ends up in landfill or incineration, contributing to environmental pollution.

Cost Considerations and Market Availability

PET-laminated paper typically incurs higher production costs due to the superior durability and chemical resistance of polyethylene terephthalate, making it less budget-friendly compared to PE-laminated paper. PE-laminated paper, favored for its cost-effectiveness and widespread availability, is commonly used in packaging applications requiring moderate moisture resistance. Market availability of PET-laminated paper is relatively limited, often reserved for premium packaging segments, while PE-laminated paper enjoys broader distribution across various industries and regional suppliers.

Typical Applications in Packaging

PET-laminated paper is commonly used in food packaging, such as snack wrappers and frozen foods, due to its excellent barrier properties against moisture and oxygen. PE-laminated paper is favored for packaging applications requiring flexibility and heat-sealability, like cartons for fresh produce, bakery items, and liquid containers. Your choice depends on the need for durability and barrier protection, with PET offering superior resistance and PE providing cost-effective, sealable solutions.

Performance in Food Safety and Freshness

PET-laminated paper offers superior barrier properties against moisture, oxygen, and grease, significantly enhancing food safety and prolonging freshness compared to PE-laminated paper. Your packaged products benefit from PET's higher heat resistance and durability, reducing the risk of contamination and spoilage during storage and transportation. PE-laminated paper provides basic protection but lacks the advanced barrier capabilities necessary for maintaining optimal food quality over extended periods.

Choosing the Right Laminate for Your Needs

PET-laminated paper offers superior durability, higher heat resistance, and excellent clarity, making it ideal for packaging requiring extended shelf life and premium presentation. PE-laminated paper provides cost-effective moisture barrier properties and flexibility, suitable for products needing effective water resistance without heavy-duty demands. Understanding your product's protection requirements and budget will guide you in selecting the laminate that ensures optimal performance and customer satisfaction.

PET-laminated paper vs PE-laminated paper Infographic

libmatt.com

libmatt.com