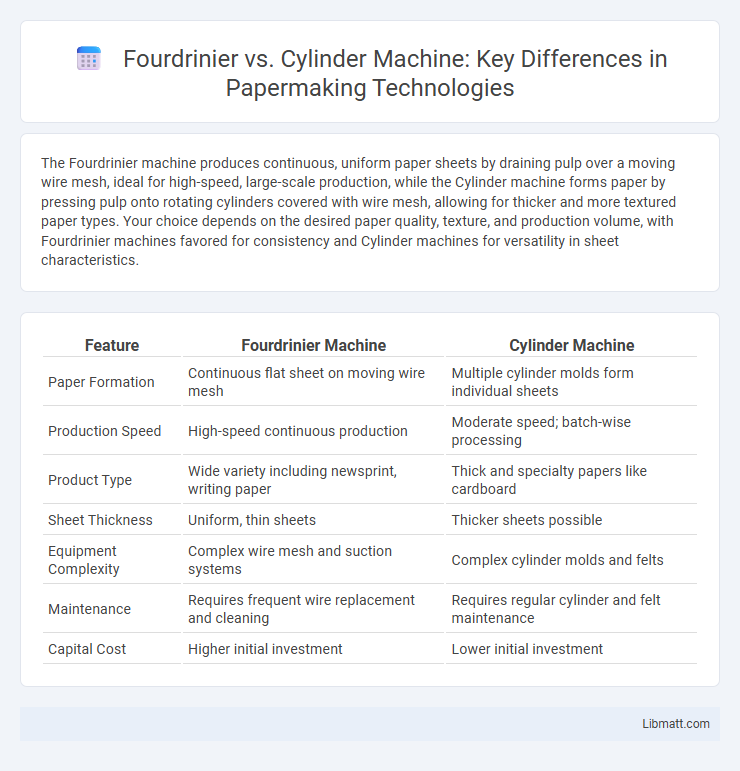

The Fourdrinier machine produces continuous, uniform paper sheets by draining pulp over a moving wire mesh, ideal for high-speed, large-scale production, while the Cylinder machine forms paper by pressing pulp onto rotating cylinders covered with wire mesh, allowing for thicker and more textured paper types. Your choice depends on the desired paper quality, texture, and production volume, with Fourdrinier machines favored for consistency and Cylinder machines for versatility in sheet characteristics.

Table of Comparison

| Feature | Fourdrinier Machine | Cylinder Machine |

|---|---|---|

| Paper Formation | Continuous flat sheet on moving wire mesh | Multiple cylinder molds form individual sheets |

| Production Speed | High-speed continuous production | Moderate speed; batch-wise processing |

| Product Type | Wide variety including newsprint, writing paper | Thick and specialty papers like cardboard |

| Sheet Thickness | Uniform, thin sheets | Thicker sheets possible |

| Equipment Complexity | Complex wire mesh and suction systems | Complex cylinder molds and felts |

| Maintenance | Requires frequent wire replacement and cleaning | Requires regular cylinder and felt maintenance |

| Capital Cost | Higher initial investment | Lower initial investment |

Introduction to Papermaking Machines

Papermaking machines such as the Fourdrinier and cylinder machines are essential in transforming pulp into continuous rolls or sheets of paper. The Fourdrinier machine uses a horizontal wire mesh to form a uniform paper web through drainage and pressing, ideal for producing high-quality, fine paper grades. Cylinder machines, on the other hand, employ rotating cylinders to shape the paper sheet, offering advantages in making thicker and specialty paper, giving you options based on your production requirements and paper type.

Overview of the Fourdrinier Machine

The Fourdrinier machine is a continuous papermaking machine that forms paper by depositing a slurry of fibers onto a moving woven wire mesh. This machine excels in producing wide rolls of uniform paper, making it ideal for high-volume production of printing and writing papers. Unlike cylinder machines, which use a rotating mold, the Fourdrinier's flat wire screen allows for more consistent paper thickness and surface quality.

Overview of the Cylinder Machine

The Cylinder Machine is a traditional papermaking device that uses a rotating cylindrical mold to form paper sheets, allowing for efficient dewatering and strong fiber bonding. Unlike the Fourdrinier Machine, which employs a continuous wire screen, the Cylinder Machine passes the slurry over a rotating wire-covered cylinder partially submerged in the pulp vat, producing thicker and more textured paper grades. Its design enables better handleability of mechanical and recycled fibers, making it ideal for specialty papers and heavier products.

Construction and Mechanism Comparison

The Fourdrinier machine features a continuous wide flat wire mesh conveyor belt that forms the paper web by draining water through the mesh, while the cylinder machine uses a rotating cylindrical mold partially submerged in pulp to form the paper sheet. In terms of construction, the Fourdrinier requires extensive wire section length and complicated dewatering systems, whereas the cylinder machine involves simpler mechanical design with multiple cylinders that can produce specialty papers and thicker sheets. Mechanically, the Fourdrinier emphasizes high-speed, wide-format production with consistent formation, contrasting with the cylinder machine's slower speed and enhanced flexibility for textured and multi-ply paper grades.

Differences in Papermaking Processes

The Fourdrinier machine produces paper by forming a continuous sheet from a slurry of pulp on a moving wire mesh, allowing water to drain through while fibers interlock. In contrast, the cylinder machine uses a series of rotating cylinders partially submerged in pulp, which pick up fibers layer by layer, creating thicker and denser paper sheets. Understanding these papermaking process differences helps you select the right machine for desired paper quality and production speed.

Quality of Paper Produced

The Fourdrinier machine produces paper with a uniform thickness and smoother surface, ideal for high-quality printing and writing applications. Cylinder machines excel in creating bulkier, more textured paper, suitable for packaging and specialty papers requiring greater stiffness. Paper quality differences stem from the continuous wire mesh in Fourdrinier systems versus the rotating mold cylinders in cylinder machines, impacting fiber orientation and sheet formation.

Production Speed and Efficiency

The Fourdrinier machine generally offers higher production speed and greater efficiency due to its continuous paper forming process, which allows for large-scale, consistent output suitable for various paper grades. Cylinder machines typically operate at slower speeds but provide better control over paper thickness and density, making them ideal for specialty papers requiring precision. Your choice between these two depends on whether production speed or paper quality and uniformity are the primary concerns.

Applications and End Uses

The Fourdrinier machine excels in producing large, continuous sheets of paper ideal for printing, writing, and packaging applications due to its efficient, high-speed operation. Cylinder machines are preferred for specialty papers, including heavy-weight cardboard, filter papers, and wallpapers, benefiting from precise layering and enhanced sheet formation. Both machines cater to diverse end uses, with Fourdrinier favoring mass production of standard grades and cylinder machines supporting niche, value-added paper products.

Advantages and Disadvantages

The Fourdrinier machine offers high-speed continuous paper production with uniform sheet formation, making it ideal for large-scale manufacturing, but it requires significant space and energy consumption. Cylinder machines provide better sheet thickness control and can handle heavier, textured papers, with lower initial investment and simpler maintenance, though they operate at slower speeds and yield less uniform sheets. Your choice depends on production volume needs, paper quality requirements, and available infrastructure.

Conclusion: Fourdrinier vs Cylinder Machine

The Fourdrinier machine offers continuous paper production with a flat wire screen, enabling higher speed and finer surface finish, ideal for lightweight and high-quality papers. Cylinder machines utilize rotating cylinders and molds, producing thicker, heavier, and more textured paper grades with better bulk and strength. Choosing between Fourdrinier and cylinder machines depends on specific production needs, such as paper type, quality requirements, and manufacturing scale.

Fourdrinier machine vs cylinder machine Infographic

libmatt.com

libmatt.com