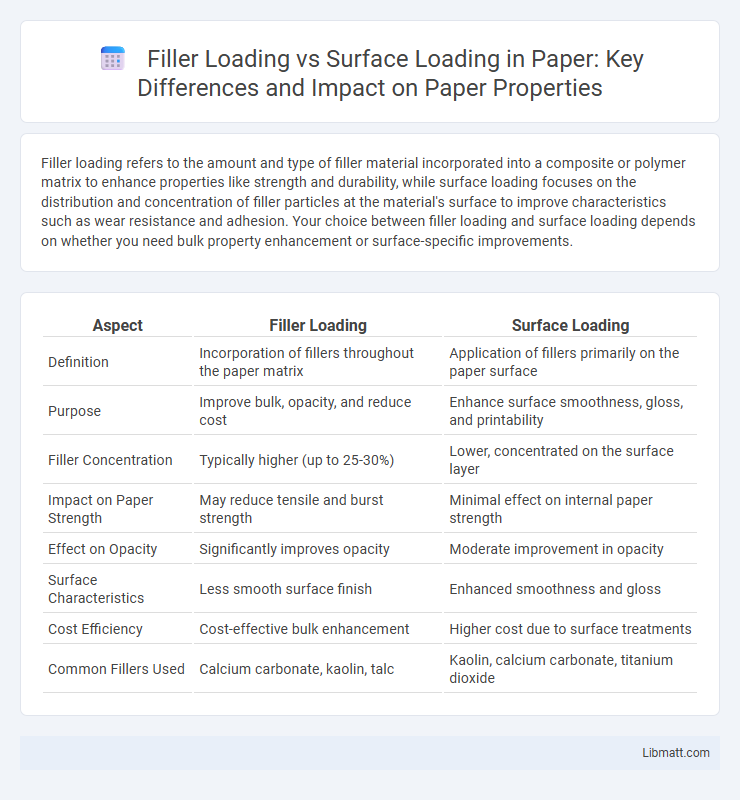

Filler loading refers to the amount and type of filler material incorporated into a composite or polymer matrix to enhance properties like strength and durability, while surface loading focuses on the distribution and concentration of filler particles at the material's surface to improve characteristics such as wear resistance and adhesion. Your choice between filler loading and surface loading depends on whether you need bulk property enhancement or surface-specific improvements.

Table of Comparison

| Aspect | Filler Loading | Surface Loading |

|---|---|---|

| Definition | Incorporation of fillers throughout the paper matrix | Application of fillers primarily on the paper surface |

| Purpose | Improve bulk, opacity, and reduce cost | Enhance surface smoothness, gloss, and printability |

| Filler Concentration | Typically higher (up to 25-30%) | Lower, concentrated on the surface layer |

| Impact on Paper Strength | May reduce tensile and burst strength | Minimal effect on internal paper strength |

| Effect on Opacity | Significantly improves opacity | Moderate improvement in opacity |

| Surface Characteristics | Less smooth surface finish | Enhanced smoothness and gloss |

| Cost Efficiency | Cost-effective bulk enhancement | Higher cost due to surface treatments |

| Common Fillers Used | Calcium carbonate, kaolin, talc | Kaolin, calcium carbonate, titanium dioxide |

Introduction to Filler Loading and Surface Loading

Filler loading employs the incorporation of particulate materials within a polymer matrix to enhance mechanical, thermal, or electrical properties by distributing fillers throughout the bulk material. Surface loading concentrates fillers primarily on the outer layer or surface of a composite, improving surface characteristics such as abrasion resistance, conductivity, or barrier properties. Your choice between these methods influences the overall performance, processing techniques, and application suitability of composite materials.

Definitions: Filler Loading vs Surface Loading

Filler loading refers to the process of incorporating particulate materials into a composite matrix to enhance mechanical, thermal, or electrical properties by volume fraction or weight percentage. Surface loading involves the deposition or placement of coatings, treatments, or additives on the external surface of a material rather than within its bulk, aiming to modify surface characteristics such as adhesion, corrosion resistance, or hydrophobicity. Understanding the distinction between filler loading, which alters bulk properties, and surface loading, which targets surface modifications, is crucial for tailoring material performance in applications like polymer composites and coatings.

Key Differences Between Filler Loading and Surface Loading

Filler loading involves incorporating fillers within the bulk of a material, enhancing properties like strength and thermal stability without significantly altering the surface appearance. Surface loading refers to applying additives or coatings onto a material's exterior, primarily improving surface characteristics such as wear resistance or hydrophobicity. The key difference lies in filler loading modifying internal structure and bulk performance, while surface loading targets exterior functionality and aesthetics.

Material Properties Influenced by Filler Loading

Filler loading significantly affects the mechanical, thermal, and electrical properties of composite materials by altering density, stiffness, and thermal conductivity. Higher filler content typically increases a material's rigidity and heat resistance but may reduce impact strength and flexibility depending on the filler type and dispersion. Understanding these changes helps optimize Your composite's performance by balancing filler loading with surface area interactions, which are critical in surface loading techniques for enhancing adhesion and surface finish.

Impact of Surface Loading on Performance

Surface loading significantly influences composite material performance by affecting stress distribution and interfacial bonding. High surface loading can enhance mechanical strength and stiffness but may lead to agglomeration and reduced impact resistance. Optimizing surface loading balances improved durability with maintaining material flexibility and toughness.

Advantages of Filler Loading Approaches

Filler loading enhances composite materials by improving mechanical strength, thermal stability, and cost-efficiency through uniform dispersion within the matrix. This approach allows for tailored material properties such as increased stiffness and improved wear resistance, which are critical in automotive and aerospace applications. Filler-loaded composites often exhibit better processability and reduced shrinkage compared to surface loading methods, optimizing overall performance and durability.

Pros and Cons of Surface Loading Techniques

Surface loading techniques offer precise control over filler placement, enhancing the mechanical properties and surface aesthetics of composites. They minimize filler waste and reduce processing time, but may lead to uneven dispersion and weak interfacial bonding, potentially compromising durability. Surface loading is ideal for applications requiring targeted reinforcement but demands careful optimization to avoid filler agglomeration and performance inconsistencies.

Applications in Industry: Filler vs Surface Loading

Filler loading enhances mechanical properties such as strength and thermal stability in polymer composites, making it ideal for automotive and aerospace applications where durability is critical. Surface loading optimizes surface characteristics like adhesion and conductivity, frequently used in coatings, electronics, and packaging industries to improve interface performance. Understanding these distinctions helps you select the right method to tailor material properties for specific industrial applications.

Comparative Analysis: Cost and Efficiency

Filler loading generally reduces material costs by incorporating inexpensive additives like calcium carbonate, enhancing bulk without significantly increasing price, but may impact mechanical properties and processing efficiency. Surface loading, involving coatings on filler particles, improves compatibility with polymer matrices, leading to better dispersion and enhanced product performance, although it increases manufacturing costs due to additional processing steps. Balancing cost-effectiveness and efficiency depends on the application-specific requirements for mechanical strength, durability, and overall production scalability.

Future Trends in Filler and Surface Loading Technologies

Filler loading and surface loading technologies are evolving rapidly, driven by advancements in nanomaterials and sustainable composites. Future trends highlight increased use of bio-based fillers combined with surface modifications to enhance mechanical properties and environmental compatibility. Your product performance can significantly improve through tailored surface treatments that optimize filler-matrix interactions for various industrial applications.

Filler loading vs surface loading Infographic

libmatt.com

libmatt.com