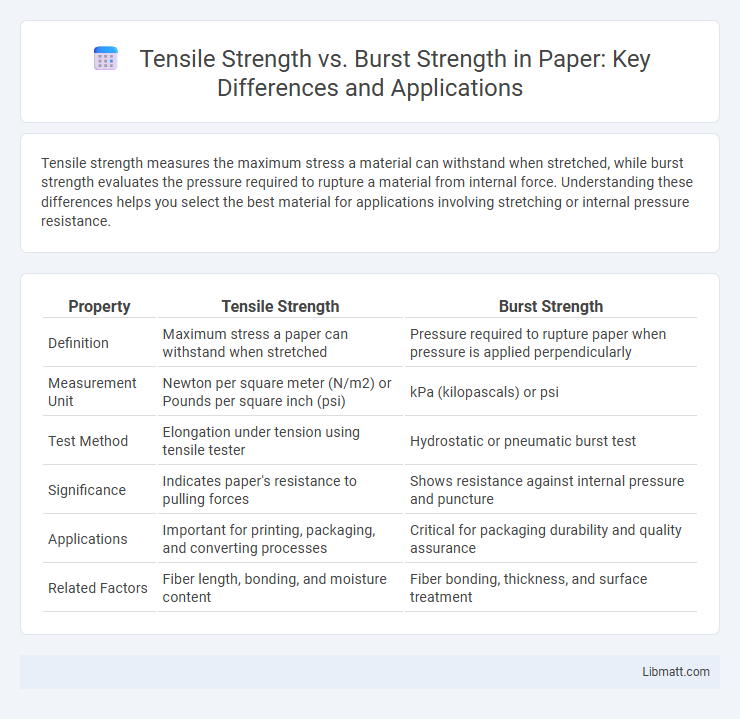

Tensile strength measures the maximum stress a material can withstand when stretched, while burst strength evaluates the pressure required to rupture a material from internal force. Understanding these differences helps you select the best material for applications involving stretching or internal pressure resistance.

Table of Comparison

| Property | Tensile Strength | Burst Strength |

|---|---|---|

| Definition | Maximum stress a paper can withstand when stretched | Pressure required to rupture paper when pressure is applied perpendicularly |

| Measurement Unit | Newton per square meter (N/m2) or Pounds per square inch (psi) | kPa (kilopascals) or psi |

| Test Method | Elongation under tension using tensile tester | Hydrostatic or pneumatic burst test |

| Significance | Indicates paper's resistance to pulling forces | Shows resistance against internal pressure and puncture |

| Applications | Important for printing, packaging, and converting processes | Critical for packaging durability and quality assurance |

| Related Factors | Fiber length, bonding, and moisture content | Fiber bonding, thickness, and surface treatment |

Introduction to Tensile Strength and Burst Strength

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking, typically expressed in units like pounds per square inch (psi) or megapascals (MPa). Burst strength refers to the pressure required to rupture a material when subjected to force applied perpendicular to its surface, commonly used in testing packaging and fabrics. Both properties are critical for evaluating durability and performance in engineering, manufacturing, and material science applications.

Defining Tensile Strength: What Does It Measure?

Tensile strength measures the maximum amount of stress a material can withstand while being stretched or pulled before breaking, indicating its resistance to tension. It evaluates how much force your material can handle in applications where stretching occurs, crucial for fabrics, metals, and plastics. Unlike burst strength, which tests pressure resistance, tensile strength specifically focuses on the material's ability to endure pulling forces without failure.

Understanding Burst Strength in Materials

Burst strength measures a material's ability to withstand internal pressure before rupture, crucial in applications like packaging and flexible containers. It is determined by quantifying the pressure required to burst a sample, often reflecting the material's resistance to puncture and deformation under stress. Unlike tensile strength, which gauges resistance to tension forces, burst strength evaluates performance under multidirectional stress conditions.

Key Differences Between Tensile and Burst Strength

Tensile strength measures the maximum stress a material can withstand while being stretched before breaking, focusing on linear force resistance. Burst strength evaluates the pressure a material can endure before rupturing, emphasizing resistance to multidirectional forces. The key difference lies in tensile strength assessing pulling forces along a single axis, whereas burst strength tests performance under internal pressure from all directions.

Testing Methods for Tensile Strength

Tensile strength testing measures the maximum force a material can withstand while being stretched before breaking, typically using a universal testing machine that applies a uniaxial load to a specimen. Common methods include the ASTM D638 standard for plastics and ASTM D5034 for textiles, where the material's elongation and force are recorded to determine its tensile strength. Unlike burst strength, which is assessed by applying pressure until rupture (following standards such as ASTM D3786), tensile strength testing provides precise data on material elasticity and ultimate failure point under tension.

How Burst Strength Is Measured

Burst strength is measured by applying increasing pressure to a material until it ruptures, typically using a Mullen tester or burst tester. This test evaluates the material's resistance to rupture under multidirectional stress, which is essential for materials like paper, cardboard, and textiles. Your product's burst strength data helps ensure it can withstand operational pressures without failure.

Material Types: When Is Tensile or Burst Strength More Important?

Tensile strength measures a material's resistance to breaking under tension, making it crucial for applications involving pulling or stretching forces, such as in fabrics, metals, and plastics. Burst strength evaluates the ability to withstand pressure applied uniformly until failure, which is essential for flexible materials like paper, packaging films, and inflatable products. Your choice between tensile and burst strength depends on whether the material must endure stretching loads or internal pressure, guiding the selection of suitable materials based on the specific mechanical demands.

Applications: Practical Uses for Both Strengths

Tensile strength is crucial in applications requiring materials to withstand pulling or stretching forces, such as in bridge cables, ropes, and fabric manufacturing where durability under tension is essential. Burst strength is vital for materials used in pressure vessels, packaging, and pipelines that must resist internal pressure without rupturing, ensuring safety and integrity under high stress. Both strengths guide engineers in selecting materials to optimize performance based on the specific mechanical demands of practical applications.

Factors Affecting Tensile and Burst Strength

Tensile strength and burst strength are influenced by material composition, thickness, and manufacturing processes. The weave pattern, fiber orientation, and adhesive bonding significantly impact tensile strength, while burst strength depends heavily on the material's ability to withstand multidirectional pressure or internal force. Understanding these factors helps you select the appropriate fabric or material for applications requiring specific strength properties.

Choosing the Right Strength Test for Your Needs

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking, making it ideal for applications involving tension. Burst strength evaluates the pressure required to rupture a material by applying force perpendicular to its surface, which is crucial for assessing resistance to internal pressure or impact. Choosing the right strength test for your needs depends on whether your application involves stretching forces or pressure, ensuring accurate performance evaluation and material reliability.

Tensile strength vs burst strength Infographic

libmatt.com

libmatt.com