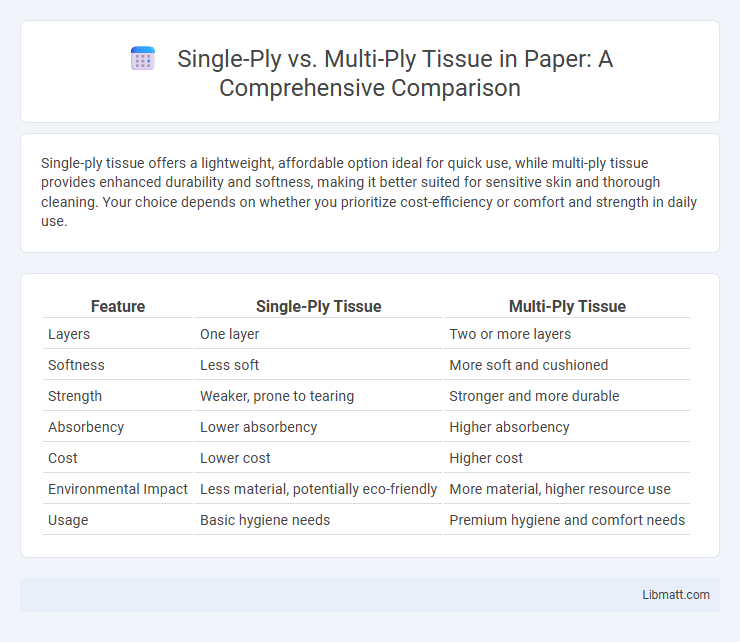

Single-ply tissue offers a lightweight, affordable option ideal for quick use, while multi-ply tissue provides enhanced durability and softness, making it better suited for sensitive skin and thorough cleaning. Your choice depends on whether you prioritize cost-efficiency or comfort and strength in daily use.

Table of Comparison

| Feature | Single-Ply Tissue | Multi-Ply Tissue |

|---|---|---|

| Layers | One layer | Two or more layers |

| Softness | Less soft | More soft and cushioned |

| Strength | Weaker, prone to tearing | Stronger and more durable |

| Absorbency | Lower absorbency | Higher absorbency |

| Cost | Lower cost | Higher cost |

| Environmental Impact | Less material, potentially eco-friendly | More material, higher resource use |

| Usage | Basic hygiene needs | Premium hygiene and comfort needs |

Introduction to Tissue Types: Single-Ply vs Multi-Ply

Single-ply tissue consists of a single layer of paper, offering a lightweight and cost-effective option primarily used in commercial and public settings. Multi-ply tissue features two or more layers, providing enhanced softness, durability, and absorbency ideal for residential bathrooms and premium commercial use. Choosing between single-ply and multi-ply depends on balancing factors such as comfort, strength, and price efficiency.

What is Single-Ply Tissue?

Single-ply tissue consists of a single layer of paper designed for lightweight use, often prioritizing softness and cost-efficiency. It is commonly used in residential or light commercial settings where moderate strength and absorbency suffice. Compared to multi-ply tissue, single-ply offers less durability but can improve airflow and reduce paper waste.

What is Multi-Ply Tissue?

Multi-ply tissue consists of two or more layers of paper bonded together, offering enhanced strength, absorbency, and softness compared to single-ply options. This construction makes multi-ply tissue ideal for your everyday needs, providing greater durability and comfort when wiping or cleaning. Manufacturers achieve these qualities by using advanced layering techniques and high-quality fibers.

Differences in Manufacturing Processes

Single-ply tissue is produced by layering fibers into a single sheet through a simpler manufacturing process, resulting in a thinner and more lightweight product. Multi-ply tissue involves bonding multiple sheets together, often using adhesives or thermal bonding techniques, which enhances strength, absorbency, and softness. Your choice between single-ply and multi-ply tissues depends on the desired durability and comfort preferences driven by these distinct manufacturing methods.

Strength and Durability Comparison

Single-ply tissue typically offers less strength and durability due to its thinner, lighter construction, making it more prone to tearing during use. Multi-ply tissue incorporates multiple layers that enhance structural integrity, resulting in greater strength, absorbency, and resistance to disintegration. Your choice between single-ply and multi-ply should consider the need for durability and comfort, with multi-ply providing a more robust and reliable option.

Softness and Comfort: User Experience

Single-ply tissue offers a lightweight, delicate feel that provides moderate softness, suitable for general use but potentially less cushioned for sensitive skin. Multi-ply tissue combines two or more layers, enhancing softness and overall comfort by adding thickness, absorbency, and durability, making it ideal for users seeking a plush, gentle experience. Consumer reviews consistently highlight multi-ply options as superior for preventing irritation and ensuring a more comfortable, luxurious touch during use.

Absorbency and Effectiveness

Single-ply tissue is generally less absorbent due to its thinner construction, making it less effective for tasks requiring higher moisture retention. Multi-ply tissue offers enhanced absorbency and durability by combining multiple layers, which improves overall effectiveness for drying and cleaning purposes. The increased thickness of multi-ply tissue allows for better liquid absorption and reduces the likelihood of tearing during use.

Cost Analysis: Single-Ply vs Multi-Ply

Single-ply tissue generally costs less due to lower manufacturing expenses and reduced material use, making it a budget-friendly option for bulk purchases. Multi-ply tissue, while more expensive, offers enhanced durability and absorbency, often justifying the higher price in environments demanding quality and comfort. Evaluating Your specific needs for cost versus performance can guide an efficient choice between single-ply and multi-ply tissue products.

Environmental Impact and Sustainability

Single-ply tissue typically generates less environmental waste due to its lighter weight and reduced material usage, leading to lower transportation emissions compared to multi-ply options. Multi-ply tissue, while offering enhanced durability and comfort, consumes more raw materials and energy during production, increasing its overall carbon footprint. Sustainability efforts often favor single-ply tissue with recycled content, which minimizes deforestation and supports eco-friendly manufacturing practices.

Choosing the Right Tissue for Your Needs

Selecting between single-ply and multi-ply tissue depends on your specific requirements for softness, strength, and cost-efficiency. Single-ply tissue offers lightweight and economical options ideal for environments prioritizing affordability and frequent replacement. Multi-ply tissue provides enhanced durability and absorbency, suitable for households or facilities seeking comfort and superior performance in hygiene products.

single-ply vs multi-ply tissue Infographic

libmatt.com

libmatt.com